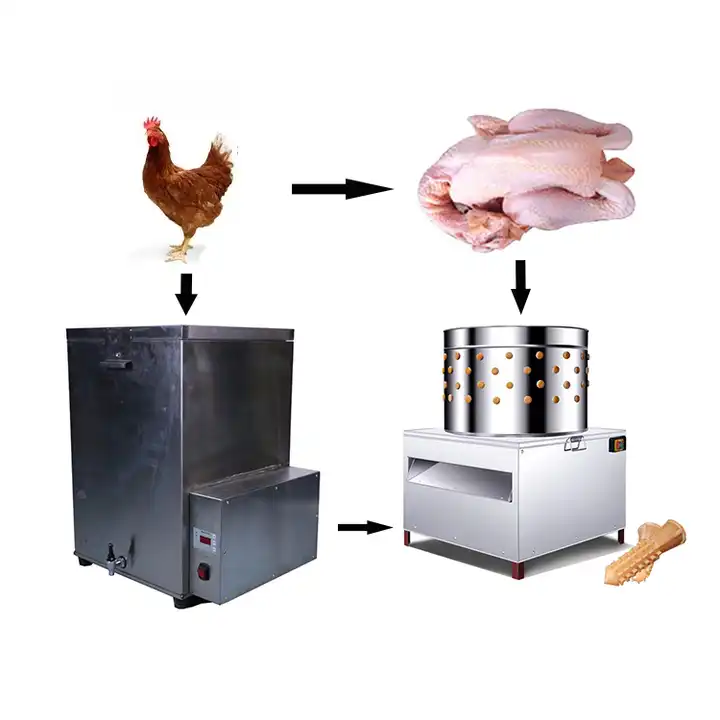

Chicken scalder plucker machine for sale poultry scalder chicken plucking machine

- 1.High-quality materials: Chicken cages are usually made of high-quality materials such as galvanized steel wire, which are corrosion-resistant, durable, and easy to clean.

- 2. Scientific design: Chicken cages are designed to provide chickens with a comfortable living environment, including adequate light, ventilation, and feeding and drinking facilities.

- 3. Easy to install and operate: Chicken cages are easy to install and operate, which can save time and labor costs.

- 4. Customization: Chicken cages can be customized according to the specific needs of farmers, including the size, capacity, and accessories.

1. Voltage : 220-240V/110V-120V

2. fowl scalding machine Power : 2 kw

3. fowl scalding machine with water tap

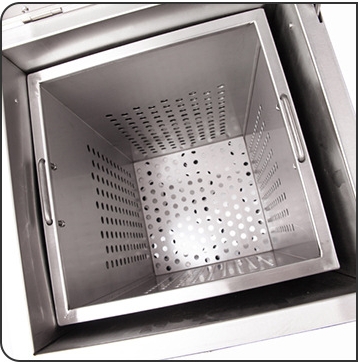

4. fowl scalding machine with stainless steel basket

5. chicken scalder machine sizes :380*460*620 mm

6. High efficient heating element

7. Auto Thermostat for over temperature automatic fault detection and recover quickly

8. On/Off Switch for easy operation

9.Large Capacity basket for ease of cleaning

*Stainless steel housing for a lifetime of service

*Has the Volume / Thermal Mass to scald 10kg batches of freshly-killed poultry in quick succession

*Much more economical to operate than a gas burner

*Easy to clean - Drain cock fitted - The heating element is covered by a removable grate

|

Model |

Voltage |

Power |

Capacity |

Weight |

Size(mm) |

|

TUNE-70 |

220-240V |

2kw |

70L |

15Kg |

350*350*600 |

|

TUNE-120 |

220-240V |

2+2Kw |

120L |

23Kg |

500*500*630 |

what is this product?

How to Use A Scalder :

- Fill the scalder with water (Keep 1/2 water box's deepnesswith water height),

- Turn the thermostat to "0" position, plug i, then swith it on. And set the thermostat to proper temperature.

- When the temperture reach the setted one, immerse the bird/chickens in the water and agitate briefly. (We recommend scalding at 80-90 degrees)

- Check if the wing feather will come out. If they can be pulled, scalding is compete. If not, dip the bird/chickens again. (Do not leave the bird in the scalder.Scald just long enough so featehrs can be picked. Leaving birds in the water causes unnecessary drops in water temperature and damages the skin.)

production.

this product application.

How to choose layer cages for your poultry farm ?

Choosing the right poultry scalder for your business involves considering several factors to ensure efficiency, safety, and compliance with industry standards. Here are some key considerations:

Capacity:

Determine the scale of your poultry operation to choose a scalder with the appropriate capacity. Consider your current needs as well as potential future growth.

Type of Poultry:

Different poultry species may require different scalding conditions. Ensure that the scalder you choose can handle the specific types of poultry you are processing.

Scalding Temperature and Time:

Understand the optimal scalding temperature and time for the type of poultry you are processing. The scalder should be capable of maintaining consistent temperatures and provide the required scalding duration.

Construction Material:

Choose a scalder made from durable and corrosion-resistant materials, typically stainless steel. This ensures longevity and ease of cleaning.

Ease of Cleaning and Maintenance:

Hygiene is critical in poultry processing. Look for a scalder with design features that facilitate easy cleaning and maintenance. Removable parts and access panels can make the cleaning process more efficient.

Energy Efficiency:

Consider the energy efficiency of the scalder. Look for features such as insulation to reduce heat loss and energy consumption. Energy-efficient equipment can contribute to cost savings in the long run.

Water Consumption:

Be mindful of water usage, as excessive water consumption can contribute to operational costs. Choose a scalder that efficiently uses water while ensuring proper scalding.

Automation and Controls:

Some scalders come with automated controls that allow for precise adjustment of temperature and other parameters. Automation can contribute to consistency in processing.

Compliance with Regulations:

Ensure that the scalder complies with local regulations and industry standards for poultry processing. This includes safety standards, hygiene regulations, and any other relevant guidelines.