Manure Belt Cleaning System: Faster, Cleaner, Cost-Saving?

Oct . 02, 2025 12:25 Back to list

Manure Belt Cleaning System: Faster, Cleaner, Cost-Saving?

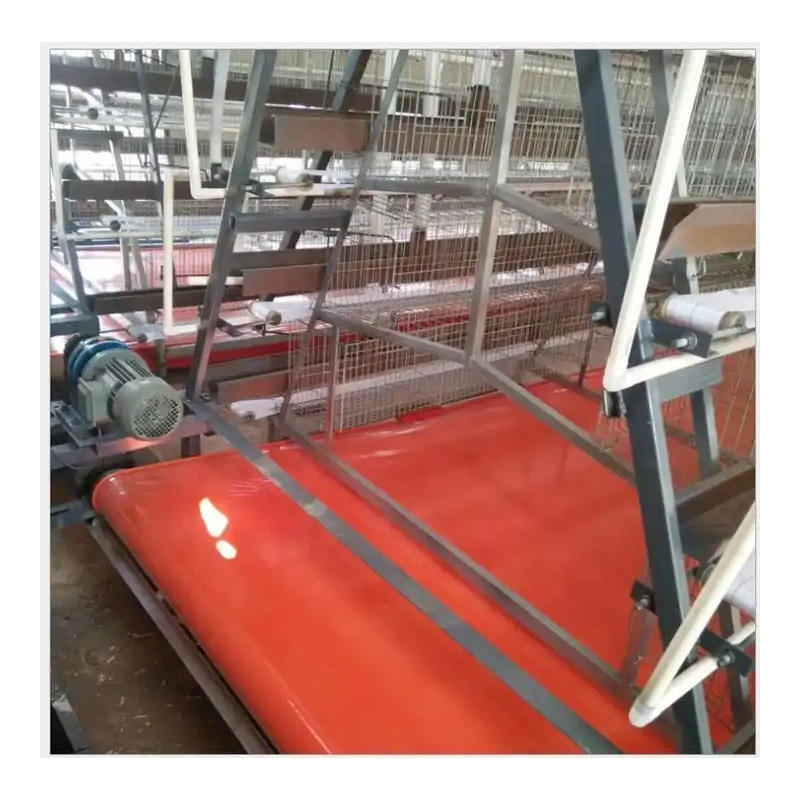

Inside Poultry Houses: The Belt That Quietly Keeps Ammonia at Bay

When you walk a long layer house on a humid morning, you can smell if the cleanout is on schedule. That’s why a modern manure belt cleaning system matters more than brochures admit. I’ve seen farms swing from chaos to clockwork just by upgrading the belt train and drive.

What’s Trending (and what actually works)

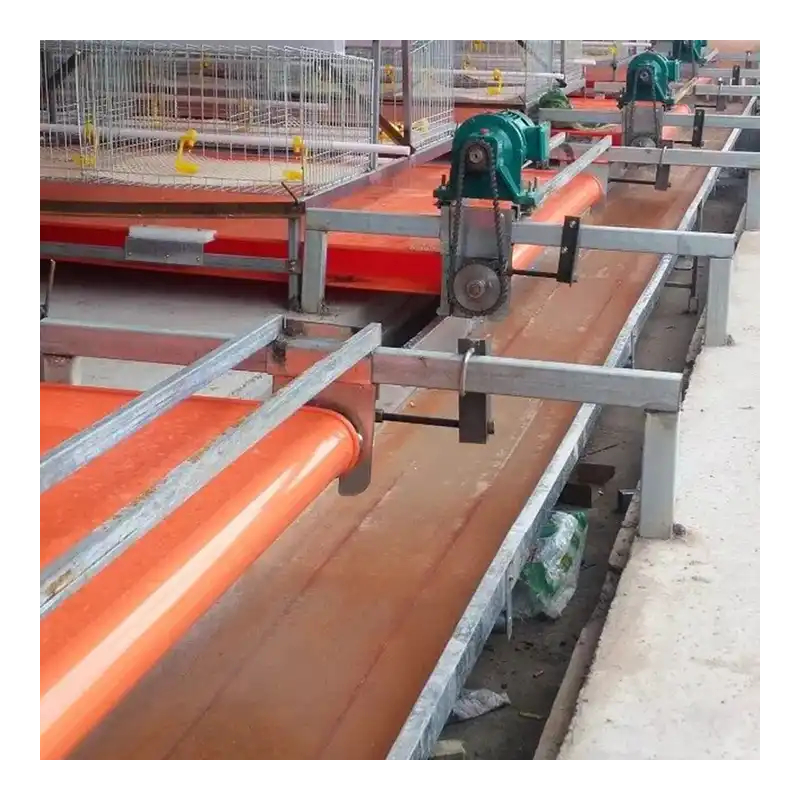

Across Asia and Eastern Europe, integrators are standardizing on galvanized frames, black-oxide sprockets, and PP/PVC composite belts. Efficiency claims are everywhere, but real farms chase three things: fewer breakdowns, lower odor, and predictable labor. The poutry Manure belt/conveyor belt for layer/broiler/chicken/battery/rabbit/duck cage from Anping, Hebei, leans into that—hot-dip galvanized frames and pulleys, simple compact structure, and a quoted 95%+ cleanout efficiency. To be honest, the “simple but compact” part is what mechanics love.

Core Specs (field-friendly)

| Parameter | Typical Spec (≈, real-world use may vary) |

|---|---|

| Belt material | PP or PVC, manure-resistant, smooth carry, anti-stick finish |

| Frame & pulleys | Hot-dip galvanized steel (ISO 1461), sprockets black-oxide treated |

| Belt width options | 200–600 mm common; custom up to 800 mm |

| Drive power | 0.75–2.2 kW IEC motor (IEC 60034-1) |

| Speed | 8–20 m/min adjustable |

| Cleanout efficiency | >95% (typical dry manure) |

| Noise | <65 dB at 1 m (≈) |

| Service life | 8–12 years belt/frame with routine maintenance |

| Certifications | CE, ISO 9001; salt-spray tested components (SGS per ISO 9227, ≈) |

| Origin | Jinwang Western Street, Industrial Zone, Anping County, Hengshui, Hebei, China |

Where it fits

- Layer and breeder houses (battery cages, multi-tier)

- Broiler parent stock, quail, duck, and rabbit cages

- Retrofits where chain scrapers underperform in high-ash manure

Many customers say the manure belt cleaning system quickly cut fly pressure and shaved two workers off night shifts. It seems that stable tracking and a decent tensioner do half the magic.

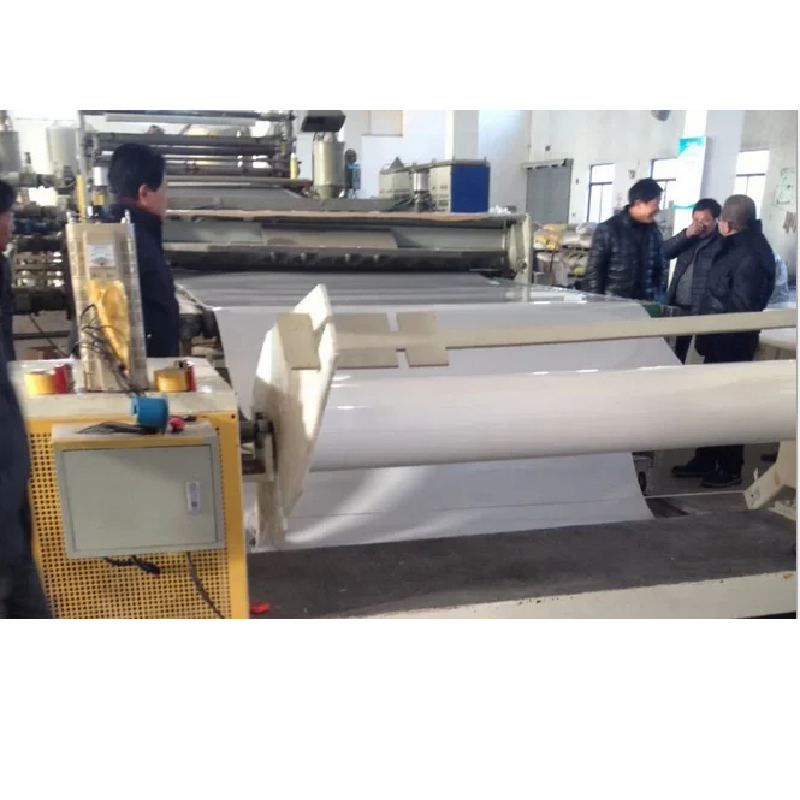

Process flow, materials, and testing

Materials: PP/PVC belt, galvanized steel frames, black-oxide sprockets, sealed bearings, IEC motors with overload protection.

Manufacturing & methods: Thorough hot-dip galvanizing per ISO 1461; sprocket oxidation to resist ammonia; dynamic balancing of pulleys (ISO 21940-11). Assembly includes belt tracking calibration and tension set.

Testing & data: Factory run-in 2 hours; belt tensile test ≈ 180–260 N/mm; salt spray on samples 72–240 h; vibration check ≤ 4.5 mm/s.

Service life: With weekly wipe-down and quarterly bearing checks, farms report 8–10 years on belts, frames longer.

Vendor snapshot (apples-to-apples, roughly)

| Vendor | Drive & Build | Protection | Efficiency | Support | Price |

|---|---|---|---|---|---|

| Yize (Anping) | Galvanized frame, black-oxide sprockets | Hot-dip galvanized | >95% | Drawings + remote commissioning | $$ |

| Local Fabricator B | Painted steel, generic sprockets | Primer paint | ~85–90% | On-call only | $ |

| EU Brand C | Stainless/galv hybrid | Powder + zinc | ~95–98% | Full on-site | $$$ |

Honestly, the middle option looks cheap upfront, but ammonia chews paint. That’s where a manure belt cleaning system with real galvanizing earns its keep.

Customization & options

- Widths, tier counts, and motor sizes matched to house length

- Stainless fasteners for coastal barns

- Sensors: belt tracking, overload, and jam detection

- Side scrapers and drip trays for wetter manure lines

Mini case files

Hebei, 50k layers: Switched from chain scrapers; ammonia down ≈18% week-on-week; crew reduced by 2 FTE; belts rinsed weekly.

GCC region, 80k broiler breeders: Upgraded to wider belts; downtime cut 32% over summer. Operator notes “stable tracking, less vibration.”

Why it’s compelling

Stable operation, low noise, overload capacity, and easy maintenance—yes, the brochure words—but in practice this manure belt cleaning system runs quietly and keeps barns breathable. Surprisingly, looks matter too: tidy, compact lines make audits easier.

References

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025