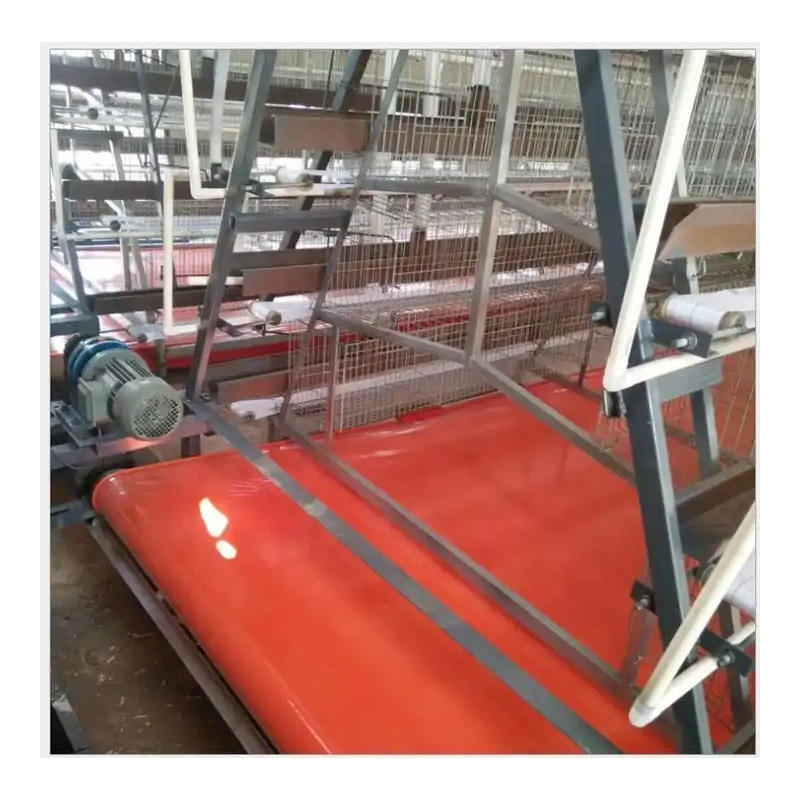

poutry Manure belt/conveyor belt for layer/broiler/chicken/battery /rabbit/duck cage

- 1.High-efficiency, more than 95% ;

- 2.Sprocket and pulley are processed by black oxide;

- 3.Thoroughly hot galvanized , anti-oxidation, a best choice for chicken house;

- 4.Simple structure but compact, easy to repair and maintenance;

- 5.Operation stable, over-load capacity,low noise and small vibration;

- 6.Compact and beautiful appearance.

*Parameters:

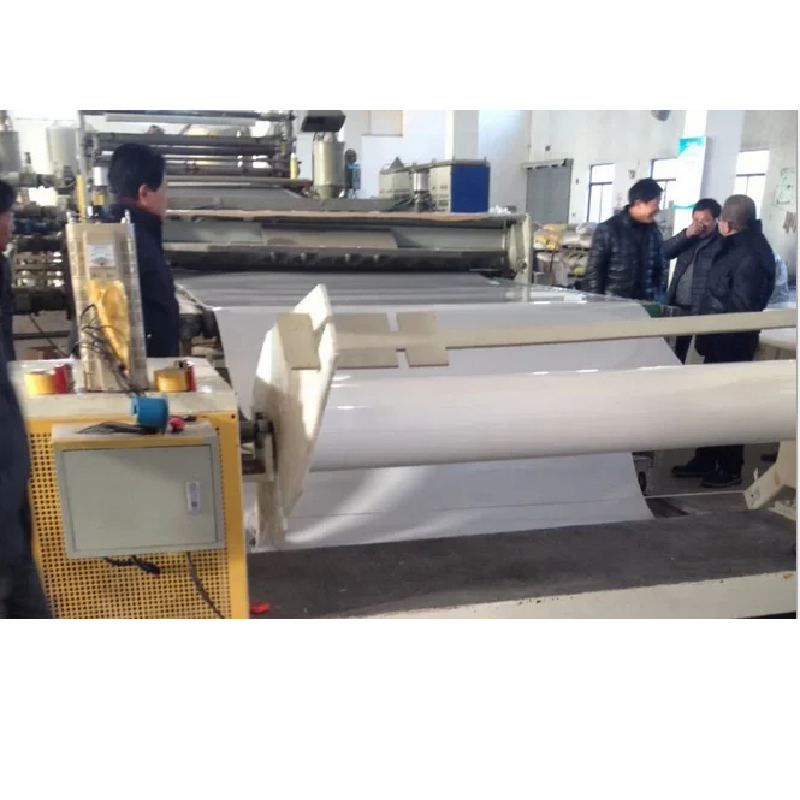

(1) Material : PP and PVC

(2) Thickness of PP material: 1m and 1.5mm

(3) Colour of PP material:White

(4) Thickness of PVC material:0.5mm-2mm

(5) Colour of PVC material : White,yellow,green

(6) Length:no limited

(7)Width:within 3m

(8) Max loading capacity :

*The Max Tensile Strenth /Mpa

-X direction ≥25

- Y direction ≥30

* The Max Tensile elongation%:

-X direction ≥550

- Y direction ≥550

* Tensile Strength(MPa)

- X direction ≥20

- Y direction ≥20

*Tear resistance/ kN/m

- X direction ≥120

- Y direction ≥120

(9) Density: 0.91g/cm3

what is this product?

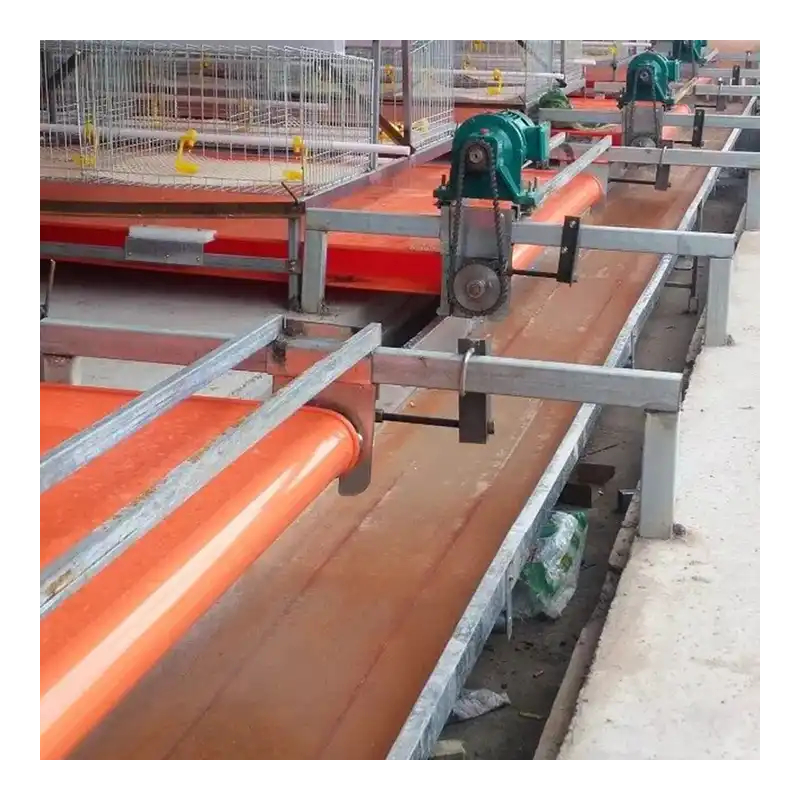

Application of poultry manure belt

A poultry manure belt is a conveyor system used in poultry farming, particularly in cage-based setups. It automatically removes and transports bird droppings away from cages, ensuring a cleaner and more hygienic environment. This automated process minimizes manual labor, contributes to waste management efficiency, and helps maintain the health of poultry by reducing disease risks. The collected manure can be directed for proper disposal or utilized as fertilizer.

this product application.

How to choose layer cages for your poultry farm ?

Choosing the right poultry manure belt for a poultry farm involves considering several factors to ensure it meets the specific needs and conditions of the farm. Here's a concise guide:

Belt Material and Durability:

Choose a manure belt made of durable and corrosion-resistant material, ensuring a long lifespan despite exposure to manure and cleaning processes.

Belt Width and Length:

Select the appropriate belt width and length based on the dimensions and layout of the poultry housing. Ensure it covers the entire cage area for efficient manure removal.

Load Capacity:

Consider the load capacity of the manure belt to handle the volume of droppings produced by the poultry in your farm. Choose a system that matches your specific flock size.

Ease of Cleaning:

Opt for a manure belt system designed for easy cleaning. Smooth and easily washable surfaces prevent the accumulation of waste and facilitate regular maintenance.

Automatic Operation:

Choose a system that offers automatic operation for continuous and efficient removal of manure. This reduces the need for manual labor and ensures timely waste management.

Belt Speed Control:

Look for a system that allows adjustable belt speed. This feature enables you to control the rate of manure removal, adapting to the specific requirements of your poultry farm.

Resistance to Environmental Factors:

Ensure the manure belt is resistant to environmental factors such as moisture, heat, and ammonia present in the poultry environment. This helps maintain the integrity of the belt over time.

Installation and Compatibility:

Select a manure belt system that is easy to install and compatible with your existing poultry housing infrastructure. Consider whether it integrates seamlessly with your overall farm setup.

Maintenance Requirements:

Assess the maintenance requirements of the system. Choose a low-maintenance manure belt that can withstand the rigors of continuous operation without frequent breakdowns.

By considering these factors, you can choose a poultry manure belt that aligns with the specific needs of your poultry farm, ensuring efficient waste management and a hygienic environment for your birds.