Manure Belt Cleaning System | Automatic, Hygienic, Durable

Oct . 27, 2025 11:35 Back to list

Manure Belt Cleaning System | Automatic, Hygienic, Durable

Practical Field Notes on a Manure Belt Cleaning System for Modern Poultry Houses

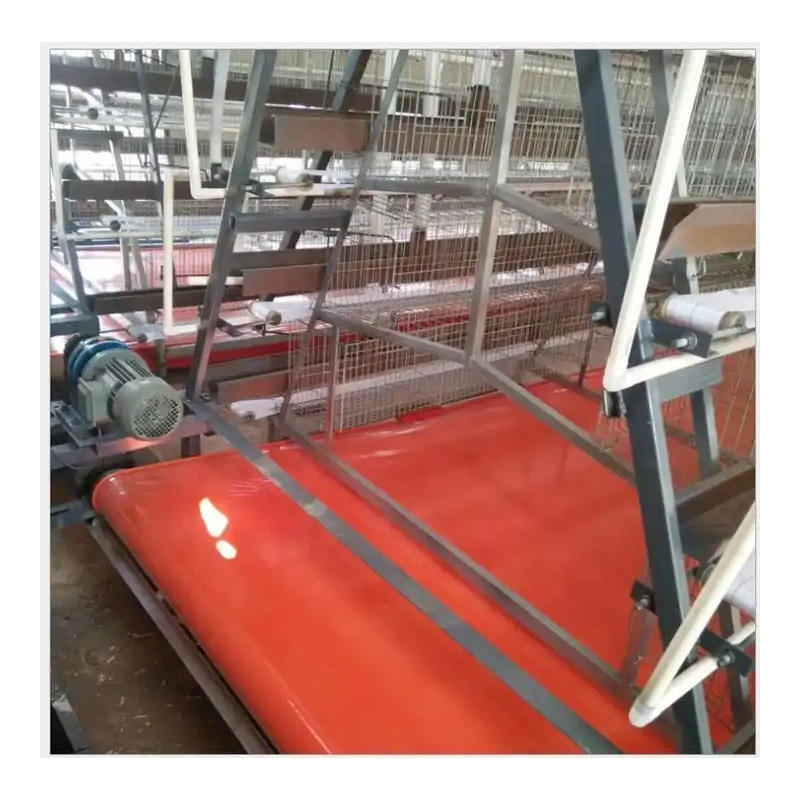

If you’ve walked a layer barn during summer, you already know: manure handling is where comfort, labor costs, and air quality collide. I’ve been in enough houses to see good systems pay for themselves. The Yize Machine unit—officially “poutry manure belt/conveyor belt for layer/broiler/chicken/battery/rabbit/duck cage”—is one I’ve tracked closely from Anping County, Hebei, which, fun fact, is a serious wire-mesh and hardware hub.

What’s moving in the industry

- Ammonia reduction goals tied to welfare audits are tightening; belts that clear ≥95% each pass are getting shortlisted.

- Hot-dip galvanized and black-oxide steel parts are back in favor—durable, easy to inspect, and friendly to wet-wash cycles.

- Data-logging of run cycles, noise, and energy is becoming standard. Not glamorous, but it helps with audits and grants.

Technical quick tour (and a few asides)

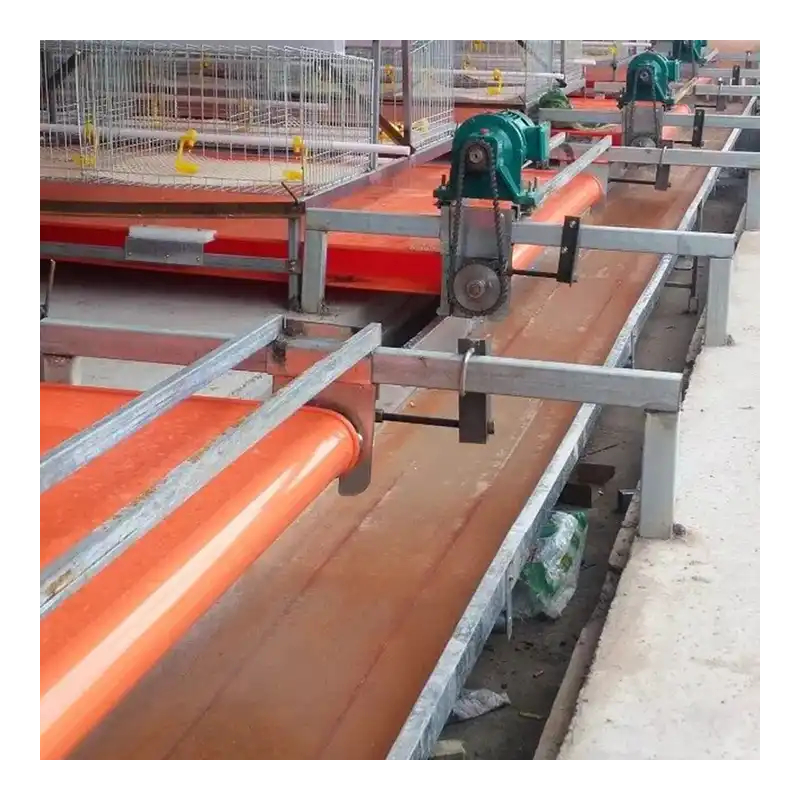

This Manure Belt Cleaning System keeps it refreshingly simple: sprocket and pulley with black-oxide finish, thoroughly hot-galvanized structure (anti-oxidation), compact layout, and a drive that runs steady with low vibration. Many customers say it’s quiet enough that birds don’t flinch—my notes put it well below normal fan noise when installed right.

Origin: Jinwang Western Street, Industrial Zone, Anping County, Hengshui City, Hebei, China. The supply chain here is mature; spare parts sourcing is surprisingly straightforward.

| Parameter | Typical value / notes |

|---|---|

| Efficiency per pass | ≥95% removal (field logs; real-world use may vary) |

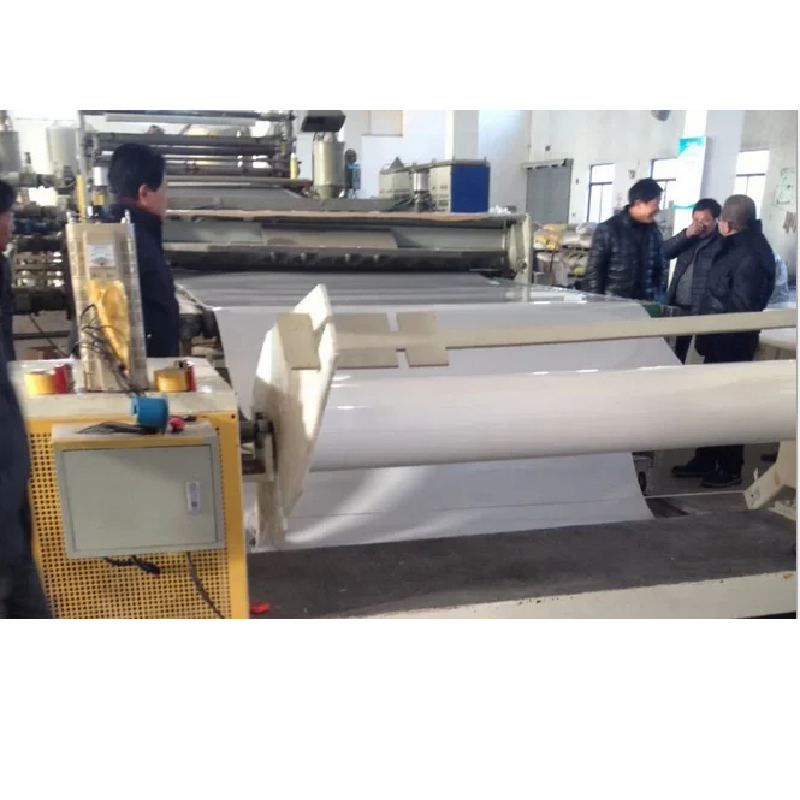

| Belt material | PP or PVC, thickness ≈0.8–1.2 mm |

| Belt width | ≈500–1200 mm (custom on request) |

| Drive speed | ≈0.2–0.4 m/s adjustable |

| Noise | <65 dB at 1 m (around fans it feels quieter) |

| Surface protection | Hot-dip galvanized frame; black-oxide sprockets/pulleys |

| Service life | ≈5–8 years typical (belt), structure longer with care |

Process flow, materials, and testing

- Materials: PP/PVC belts; galvanized steel frames (ISO 1461 reference), black-oxide sprockets.

- Fabrication & assembly: jig-welded frames; balanced rollers (ISO 21940 guidance); guarded drive per IEC/EN 60204-1.

- Quality checks: belt tensile (ASTM D638), splice pull tests, salt-spray spot checks on samples (ASTM B117), run-in for vibration/noise.

- Commissioning: belt tracking, scraper adjustment, timed cycles (2–6 runs/day typical).

- Service cycle: scraper edge checks monthly; belts wiped/washed; gearmotor grease per OEM spec.

Where it fits best

Layer/broiler battery cages, multi-tier duck and rabbit cages, retrofits in 2–6 tier houses, and new greenfield builds chasing tighter ammonia targets. Honestly, it shines in barns that want fewer wheelbarrows and more predictable labor.

| Vendor | Origin | Surface treatment | Efficiency | Noise | Warranty |

|---|---|---|---|---|---|

| Yize Machine | Anping, Hebei, CN | Hot-dip galvanized + black oxide | ≥95% | Low (≈<65 dB) | 12–24 months (confirm) |

| Vendor B | EU | Powder coat | ≈90–93% | Medium | 12 months |

| Vendor C | US | Galvanized | ≈92–95% | Low–Medium | 12–18 months |

Customization

- Belt width/length, edge sealing, scraper hardness options.

- Drive power and speed profiles; single or multiple discharge points.

- Auto-wash kits, ammonia sensors tie-in, stainless fasteners for wet barns.

Two quick case notes

Layer farm, 60,000 birds: After installing the Manure Belt Cleaning System, daily labor dropped ≈4 hours, in-barn NH3 measured down ~25% at 1.5 m height during peak load (portable meter; farm logs). Downtime: negligible over first 8 months.

Broiler parent stock, 3-tier: Belt tracking upgrade and new scrapers cut clean-up runs from 6 to 4/day; energy use down ≈12%. Not scientific, but consistent across a quarter.

Standards and paperwork buyers usually ask for

- Hot-dip galvanizing per ISO 1461; optional salt-spray evidence (ASTM B117 samples).

- Electrical safety IEC/EN 60204-1, guards and E-stops noted.

- Belt tensile tests (ASTM D638) and basic balance checks (ISO 21940).

- Common certifications requested: CE declaration, ISO 9001 QMS—ask for the latest PDFs.

Citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel products.

- IEC/EN 60204-1: Safety of machinery – Electrical equipment of machines.

- ASTM D638: Standard Test Method for Tensile Properties of Plastics.

- FAO. Manure management guidelines for livestock systems, ammonia mitigation overview.

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025

-

What is a Silo Automatico? Industry Applications, Benefits & Future Trends

NewsNov.20,2025