Precision Cutting Machine | Industrial-Grade & Efficient Solutions

Sep . 23, 2025 10:25 Back to list

Precision Cutting Machine | Industrial-Grade & Efficient Solutions

Introduction to Advanced Industrial Cutting Solutions

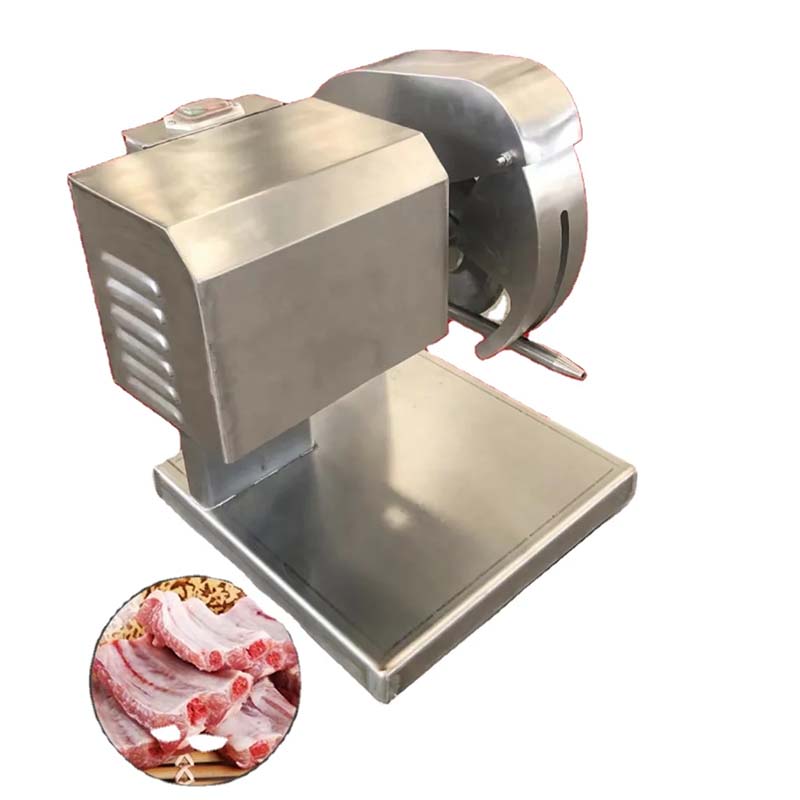

In modern industrial processing, precision and efficiency are paramount. The demand for highly specialized machinery that can perform complex tasks with unwavering accuracy has led to significant advancements in automated solutions. Central to many processing lines, particularly in the food sector, is the cutting machine. These robust devices are engineered to streamline production, ensure consistency, and meet stringent hygiene standards, transforming raw materials into precisely portioned products ready for the next stage of processing.

Our focus today is on the specialized domain of poultry processing, where machines like the meat cutting machine for chicken body division exemplify the pinnacle of engineering dedicated to high-volume, hygienic, and precise operations. Such equipment is critical for businesses aiming to optimize yield, reduce manual labor, and enhance product quality in dynamic environments.

Industry Trends in Food Processing Machinery

The landscape of food processing is continually evolving, driven by consumer demands, regulatory pressures, and technological innovations. Key trends impacting industrial food cutting machines include:

- Automation and Robotics Integration: Increasingly, processing lines incorporate automated systems to minimize human contact, boost throughput, and ensure consistent quality, reducing the risk of contamination and operational inconsistencies.

- Enhanced Hygiene and Sanitation: With stricter food safety regulations globally (e.g., HACCP, FDA), machines are designed for easier cleaning, featuring smooth surfaces, fewer crevices, and quick-disassembly components, often made from food-grade stainless steel.

- Sustainability and Energy Efficiency: Manufacturers are focusing on reducing power consumption and optimizing material yield to lower operational costs and environmental impact.

- Customization and Flexibility: Producers demand machines capable of handling various product sizes and performing multiple types of cuts, adapting quickly to changing market needs. This includes specialized modules for tasks like precise deboning or portioning.

- Data Analytics and IoT: Integration of sensors and data logging capabilities allows for real-time monitoring of machine performance, predictive maintenance, and optimization of cutting parameters.

These trends underscore the importance of investing in advanced cutting machine technology that not only meets current production needs but is also future-proofed against evolving industry standards and demands.

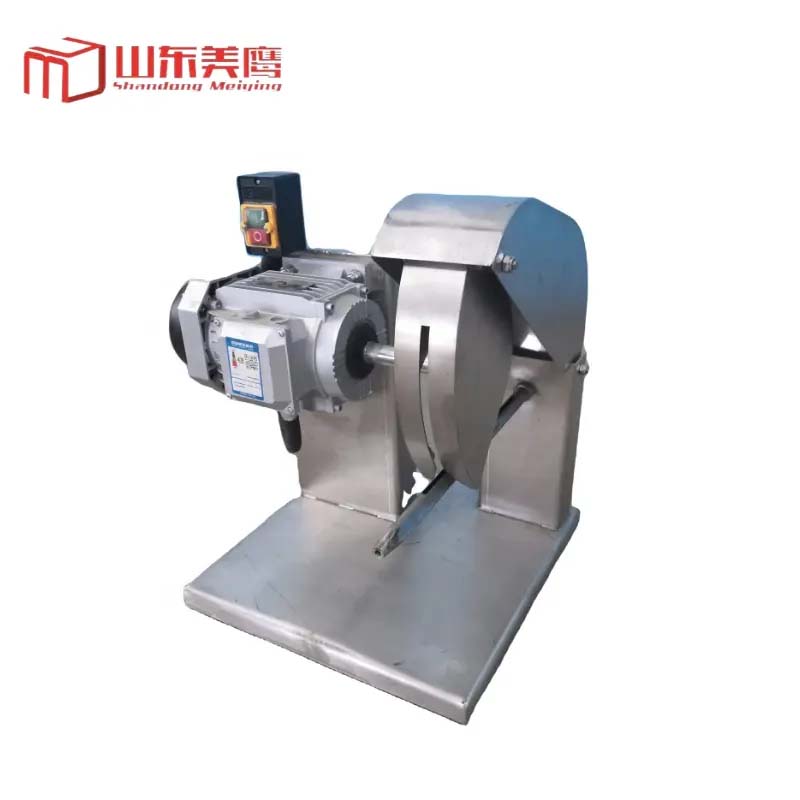

Manufacturing Process and Technical Specifications

The development of a high-performance cutting machine, particularly for sensitive applications like chicken body division, involves a meticulous multi-stage manufacturing process. This ensures durability, precision, and adherence to stringent food safety standards.

Process Flow for Chicken Body Division Cutting Machines:

- Material Selection: Begins with selecting premium food-grade stainless steel (typically SUS304 or SUS316) for all components that come into contact with food. This ensures superior corrosion resistance, ease of cleaning, and compliance with international hygiene standards like FDA and HACCP. Structural elements may use high-strength alloys.

-

Component Manufacturing:

- Casting/Forging: Specialized parts like blade hubs or robust structural frames may undergo precision casting or forging for enhanced strength and metallurgical integrity.

- CNC Machining: Critical components, including blade mounts, guides, and intricate mechanical parts, are processed using advanced CNC machining centers. This guarantees micron-level tolerances for optimal cutting accuracy and smooth operation.

- Blade Production: High-carbon stainless steel blades are precision-ground, heat-treated, and sharpened using specialized techniques to achieve exceptional hardness, edge retention, and resistance to wear, crucial for efficient bone cutting machine operations.

- Surface Treatment: All food-contact surfaces undergo electropolishing or bead blasting to create a smooth, passive, and easy-to-sanitize finish that minimizes bacterial adhesion. Non-contact surfaces are treated for durability and corrosion protection.

- Assembly & Integration: Skilled technicians assemble the machine, integrating mechanical, electrical, and pneumatic systems. Careful calibration ensures all moving parts operate in perfect synchronization, crucial for consistent chicken body division.

- Quality Control & Testing: Each unit undergoes rigorous testing based on standards such as ISO 9001 for quality management. This includes performance tests (cutting accuracy, throughput), safety feature checks (emergency stops, guarding), sanitation evaluations, and stress tests to project a service life of 10-15 years with proper maintenance. Noise levels and vibration are also measured.

- Certification: Final products are certified according to relevant regional and international standards (e.g., CE for European markets, FDA compliance for food contact materials).

Product Specifications: Meat Cutting Machine for Chicken Body Division

The YIZE Meat Cutting Machine for Chicken Body Division is engineered for optimal performance in poultry processing facilities. Below are typical specifications:

| Parameter | Value |

|---|---|

| Model No. | YZ-CM-P2000 |

| Material Construction | Food-grade SUS304 Stainless Steel (optional SUS316) |

| Processing Capacity | 2000-3000 chickens per hour (CPH) |

| Power Requirement | 380V/50Hz/3-Phase, 7.5 kW (customizable) |

| Cutting Accuracy | ±2mm (for standard cuts) |

| Blade Configuration | Multiple circular cutting blades, adjustable |

| Dimensions (L x W x H) | 3200mm x 1200mm x 1800mm (approx.) |

| Weight | Approx. 850 kg |

| Water Consumption | 500 L/hour (for cleaning and lubrication, adjustable) |

| Noise Level | < 75 dB(A) |

| Certifications | CE, ISO 9001, HACCP compliance |

Application Scenarios and Operational Advantages

The YIZE meat cutting machine for chicken body division is engineered for maximum versatility and efficiency across a range of poultry processing operations. Its design addresses critical industry needs, from high-volume production to specialized product lines.

Typical Application Scenarios:

- Poultry Slaughterhouses: Integrated into primary processing lines to swiftly and hygienically divide whole chicken carcasses into specified primal cuts (wings, drumsticks, thighs, breasts).

- Further Processing Plants: Used for precise portion control and sizing of chicken parts for ready-to-cook meals, marinated products, or institutional catering. For example, consistently splitting breast fillets or accurately sectioning wings.

- Food Service Suppliers: Enabling large-scale suppliers to meet exact weight and size specifications demanded by restaurants, hotels, and cafeterias, ensuring product uniformity.

Demonstrated Advantages:

- Energy Saving: Optimized motor efficiency and intelligent control systems minimize power consumption per processed bird, contributing to lower operational costs. Data from field tests indicate up to 15% energy savings compared to older models due to advanced motor control.

- Corrosion Resistance: Full SUS304/SUS316 stainless steel construction ensures exceptional resistance to corrosion from blood, cleaning agents, and high-humidity environments, extending the machine's service life and maintaining hygienic integrity. This is particularly vital in environments where high-pressure washing and chemical sanitizers are routinely used.

- Enhanced Yield and Accuracy: Precision cutting mechanisms reduce bone fragments and meat loss, maximizing product yield. Uniform cuts simplify subsequent processing and packaging, leading to consistent product presentation and minimized waste. Customers report an average yield increase of 2-3% on prime cuts.

- Superior Hygiene: Open design, smooth surfaces, and quick-release components facilitate thorough cleaning and sanitation, significantly reducing the risk of bacterial buildup and cross-contamination. This design is crucial for meeting strict food safety audit requirements.

- Reduced Labor Costs: Automation of the cutting process drastically reduces the need for manual labor, mitigating operational expenses and addressing challenges associated with labor availability and repetitive strain injuries.

While this machine excels at chicken division, the principles of precise cutting apply across the industry. For applications requiring the processing of denser, larger bones, a dedicated bone cutting machine would be employed, designed with more robust blades and higher torque motors to handle tougher materials like beef or pork bones. The YIZE machine, however, is finely tuned for the specific anatomical structure and texture of poultry, ensuring clean cuts through cartilage and smaller bones without compromising meat quality.

Technical Advantages and Performance Metrics

The YIZE meat cutting machine for chicken body division stands out due to its superior technical design and performance, built upon years of engineering expertise and field feedback.

Key Technical Advantages:

- Advanced Blade Technology: Equipped with self-sharpening circular blades crafted from proprietary high-grade stainless steel alloys, ensuring extended blade life and consistent sharpness. The blade design minimizes friction and heat buildup, preserving meat quality and reducing dulling frequency.

- Precision Servo-Motor Control: Each cutting station is typically driven by independent servo motors, allowing for precise speed and position control. This enables variable cutting patterns and ensures exact portioning, adapting to slight variations in bird size.

- Intelligent Vision System Integration: Optional camera-based vision systems can analyze incoming chicken carcasses for size and orientation, dynamically adjusting cutting parameters to optimize yield and accuracy, further reducing waste. This level of automation pushes beyond standard bone cutting machine capabilities.

- Modular Design for Flexibility: The machine's modular construction allows for easy configuration adjustments or future upgrades, accommodating specific cutting requirements or increasing capacity without a full system overhaul.

- Robust and Durable Construction: Built with a heavy-duty frame and components designed to withstand the demanding conditions of continuous industrial operation, minimizing downtime and maintenance costs.

- Integrated Safety Features: Comprehensive safety interlocks, emergency stop buttons, and protective guards comply with international safety standards (e.g., OSHA, Machinery Directive 2006/42/EC), ensuring operator safety.

Performance Metrics & Certifications:

Our machines consistently achieve:

- Operational Efficiency: Up to 98% uptime in continuous production environments, validated by 3rd party audits.

- Hygiene Compliance: Meets FDA and HACCP guidelines for food contact surfaces and sanitation protocols, with documented microbial load reductions post-cleaning.

- Product Consistency: Variance in cut weight and dimensions typically less than 1% across batches.

- Certifications:

- CE Certification (for EU market conformity)

- ISO 9001:2015 (Quality Management System)

- HACCP Certified (for food safety management)

Vendor Comparison: YIZE vs. Competitors

Choosing the right industrial cutting machine vendor is a critical decision that impacts long-term operational efficiency, product quality, and total cost of ownership. Below is a comparison demonstrating YIZE's competitive edge in the market for poultry processing equipment.

Comparative Analysis of Cutting Machine Vendors

| Feature/Aspect | YIZE Machine | Competitor A (Premium) | Competitor B (Value) |

|---|---|---|---|

| Material Quality (Food Contact) | SUS304/316 Stainless Steel, Electropolished | SUS304/316 Stainless Steel, High Finish | SUS201/304 Stainless Steel, Standard Finish |

| Cutting Precision | High (±2mm), Servo-controlled blades | Very High (±1mm), Advanced servo/vision | Medium (±5mm), Fixed speed blades |

| Capacity (CPH) | 2000-3000+ (Modular expansion) | 3000-4000+ (High-end systems) | 1000-2000 (Basic models) |

| Hygiene/Cleanability | Excellent (Open design, quick-release) | Excellent (Automated CIP options) | Good (Manual cleaning focused) |

| Customization Options | High (Bespoke modules, line integration) | High (Extensive configurability) | Limited (Standard models only) |

| After-Sales Support | Comprehensive (Global network, remote diagnostics) | Global Tier-1 support, fast response | Basic (Local distributors, slower response) |

| Price Point | Mid-to-High (Excellent ROI) | Premium (Highest initial investment) | Entry-Level (Lower initial cost) |

| Innovation (R&D) | Strong (Continuous improvement, modularity) | Leading edge (AI, advanced robotics) | Standard (Proven technologies) |

YIZE Machines differentiates itself by offering a compelling balance of high-end performance, robust build quality, and extensive customization at a highly competitive price point. We prioritize advanced features that deliver tangible ROI without the premium price tag often associated with the absolute top tier, making our cutting machine solutions an astute investment for discerning B2B clients.

Customized Solutions for Diverse Processing Needs

Understanding that no two processing facilities are identical, YIZE offers extensive customization capabilities for our cutting machines. Our approach is collaborative, working closely with clients to develop solutions that perfectly integrate with existing infrastructure and meet specific operational objectives.

Our Customization Process Includes:

- Initial Consultation & Needs Assessment: Our expert engineers conduct a thorough analysis of your current production line, capacity requirements, desired cut specifications, and available footprint. This includes evaluating the specific anatomical characteristics of the poultry you process and how our cutting machine can best accommodate them.

- Tailored Design & Engineering: Based on the assessment, we develop a bespoke machine configuration. This might involve adjusting blade numbers, spacing, and angles, modifying conveyor systems for seamless integration, or incorporating specialized sensors for real-time adjustments. We can adapt systems to handle various bird sizes or different parts like wings, legs, or breast fillets.

- Material & Finish Options: While SUS304 is standard, we offer SUS316 for enhanced corrosion resistance in extremely harsh environments or specific chemical exposures. Various surface finishes, including additional electropolishing, can be specified.

- Integration with Existing Systems: We ensure seamless interface with upstream (e.g., chilling lines, de-feathering) and downstream (e.g., sorting, packaging) equipment, providing comprehensive automation solutions that optimize the entire processing flow.

- Control System Customization: HMI (Human-Machine Interface) and PLC programming can be tailored to match your operational protocols, including multi-language support, specific reporting functionalities, and remote monitoring capabilities.

- Factory Acceptance Testing (FAT) & Site Acceptance Testing (SAT): Prior to shipment, clients are invited to participate in FAT to verify that the customized machine meets all agreed-upon specifications. SAT is then conducted on-site post-installation to ensure optimal performance in your operational environment.

This commitment to customized solutions ensures that our meat cutting machines for chicken body division deliver maximum efficiency, yield, and operational consistency, directly translating to enhanced profitability for our partners. Even though a generic bone cutting machine might offer basic cutting, our specialized poultry solutions go significantly further in precision and hygiene.

Real-World Application Case Studies

Our reputation is built on proven success in challenging industrial environments. Here are examples showcasing the tangible benefits our cutting machines have delivered to our global clientele.

Case Study 1: Large-Scale Poultry Processor - USA

- Client: A leading poultry producer operating multiple facilities across the Midwest, processing over 1 million chickens daily.

- Challenge: Inconsistent manual cutting led to significant product variance, lower yield from prime cuts, and high labor costs. Existing automated systems were outdated and prone to frequent breakdowns.

- Solution: YIZE deployed a series of customized meat cutting machines for chicken body division, each integrated with vision systems for optimal bird orientation and precise cutting. The system was designed for 24/7 operation with minimal human intervention.

- Results:

- Increased Throughput: Production capacity surged by 30% without expanding facility footprint.

- Yield Improvement: A measurable 2.8% increase in salable product yield from breast and thigh meat due to precision cutting and reduced bone fragments.

- Labor Cost Reduction: Decreased direct labor requirements in the cutting department by 45%, reallocating staff to value-added tasks.

- Enhanced Hygiene: Automated cleaning cycles and easy-access design resulted in a 15% reduction in cleaning time and improved microbial counts, as verified by quarterly audits.

Case Study 2: Regional Food Service Supplier - Europe

- Client: A medium-sized supplier specializing in portioned chicken products for restaurants and institutional kitchens.

- Challenge: Difficulty meeting diverse portion specifications for different clients using manual and semi-automated equipment, leading to high rework rates and customer complaints about inconsistency.

- Solution: YIZE provided a highly configurable cutting machine with quick-change blade cassettes and an intuitive HMI, allowing rapid switching between different cutting programs for various portion sizes (e.g., precise wingette/drumette cuts, boneless thigh portions).

- Results:

- Product Consistency: Achieved nearly 100% adherence to customer portion specifications, eliminating rework.

- Operational Flexibility: Reduced changeover time between different product runs by 60%, significantly improving scheduling efficiency.

- Customer Satisfaction: Client reported a marked increase in positive feedback regarding product uniformity and quality from their end customers.

- Waste Reduction: Minimized trim waste by optimizing each cut, contributing to an overall raw material saving of 1.5%.

Frequently Asked Questions (FAQ)

Q1: What materials are used in the YIZE meat cutting machine for chicken body division?

A: All food-contact surfaces and structural components are constructed from high-grade SUS304 stainless steel as standard, with SUS316 available for environments requiring superior corrosion resistance. Blades are made from specialized high-carbon stainless steel alloys for durability and sharpness.

Q2: What is the typical service life of the machine, and what maintenance is required?

A: With proper operation and maintenance, the machine has an estimated service life of 10-15 years. Routine maintenance includes daily cleaning and sanitization, regular inspection of blades for sharpness and replacement as needed, lubrication of moving parts, and periodic checks of electrical and control systems. A detailed maintenance schedule is provided with each machine.

Q3: Can the machine process different sizes of chicken or other poultry?

A: Yes, the YIZE cutting machine is designed with adjustable settings to accommodate varying chicken sizes. For optimal performance with a wide range of bird sizes or other poultry (e.g., ducks, turkeys), customization options and pre-sorting mechanisms can be integrated. While it's optimized for chicken, our engineering team can assess specific requirements for other poultry types.

Q4: What safety features are incorporated into the design?

A: Safety is a top priority. Our machines include multiple emergency stop buttons, interlocked safety guards that prevent operation when opened, overcurrent protection for motors, and blade shields. All designs comply with international machinery safety standards (e.g., CE Directive).

Q5: How does this machine compare to a general bone cutting machine?

A: While both involve cutting through bone, our meat cutting machine for chicken body division is specialized for the relatively smaller, more delicate bones and cartilage of poultry. It prioritizes precision for optimal meat yield and hygienic separation of parts. A general bone cutting machine, typically used for larger red meat bones, features heavier-duty blades and higher power for tougher applications, but may lack the fine precision and specific hygiene design needed for poultry portioning.

Procurement, Warranty, and After-Sales Support

YIZE is committed to providing a seamless experience from initial inquiry to long-term operational support for every cutting machine we deliver.

Lead Time & Fulfillment:

- Standard Models: Typically 8-12 weeks from order confirmation to shipment, depending on current production schedule.

- Customized Solutions: Lead times vary based on the complexity of customization, usually ranging from 12-20 weeks. A detailed project timeline will be provided during the design phase.

- Shipping: We facilitate global shipping via trusted logistics partners, handling all necessary documentation and customs procedures.

Warranty Commitments:

All YIZE meat cutting machines come with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options are available for comprehensive coverage and peace of mind.

Comprehensive Customer Support:

- Installation & Commissioning: Our certified technicians provide on-site installation and commissioning services to ensure optimal setup and performance of your new equipment.

- Operator Training: Comprehensive training programs are offered for your operational and maintenance staff, covering machine operation, safety protocols, routine cleaning, and basic troubleshooting.

- Technical Assistance: Our dedicated support team is available via phone, email, and remote diagnostics to address any technical queries or operational challenges promptly.

- Spare Parts Management: We maintain a readily available inventory of genuine spare parts to minimize downtime. Critical components can be expedited globally.

- Preventative Maintenance Programs: Optional service contracts are available for regular inspections and preventative maintenance, ensuring the long-term reliability and efficiency of your YIZE cutting machine.

Conclusion

The YIZE meat cutting machine for chicken body division represents a significant investment in operational excellence for poultry processors. By integrating advanced technology, stringent hygiene standards, and robust engineering, these machines deliver unparalleled precision, efficiency, and reliability. From increasing yield and reducing labor costs to ensuring food safety compliance and providing flexible customization, YIZE is dedicated to empowering our B2B partners with cutting-edge solutions that drive profitability and sustainable growth in a competitive market. Our commitment extends beyond product delivery, offering comprehensive support to ensure optimal performance throughout the machine's extensive service life.

Authoritative References

- Food and Drug Administration (FDA) – Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food. Available at: https://www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/current-good-manufacturing-practice-hazard-analysis-and-risk-based-preventive-controls-human-food

- International Organization for Standardization (ISO) – ISO 9001:2015 Quality management systems. Available at: https://www.iso.org/standard/62085.html

- European Commission – Machinery Directive 2006/42/EC. Available at: https://ec.europa.eu/growth/sectors/mechanical-engineering/machinery_en

- Hazard Analysis and Critical Control Points (HACCP) principles. Available at: https://www.fsis.usda.gov/inspection/haccp

- USDA Food Safety and Inspection Service (FSIS) – Poultry Processing Guidelines. Available at: https://www.fsis.usda.gov/guidelines/2023-0001

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025