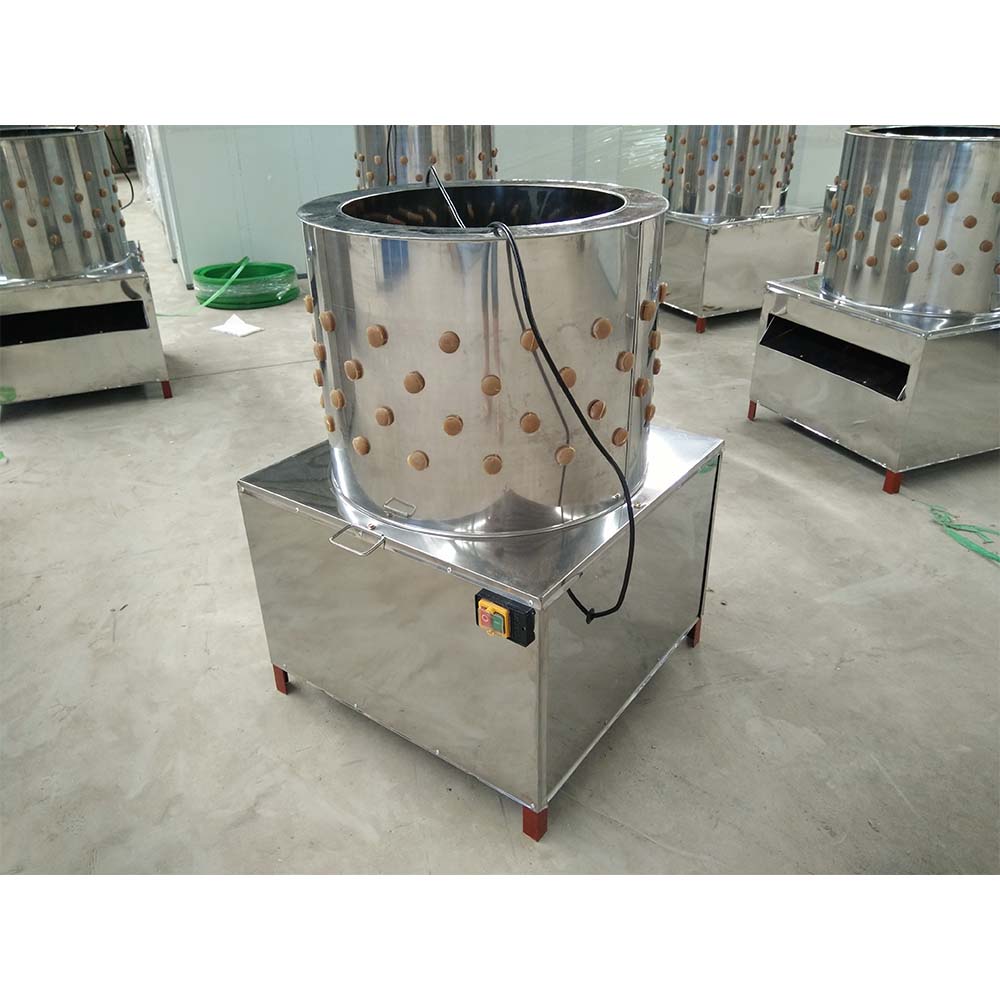

Automatic Whole Control 500bph Chicken Plucker Machine Slaughter Equipment for Wholesale

Chicken Slaughter Line Poultry Equipment

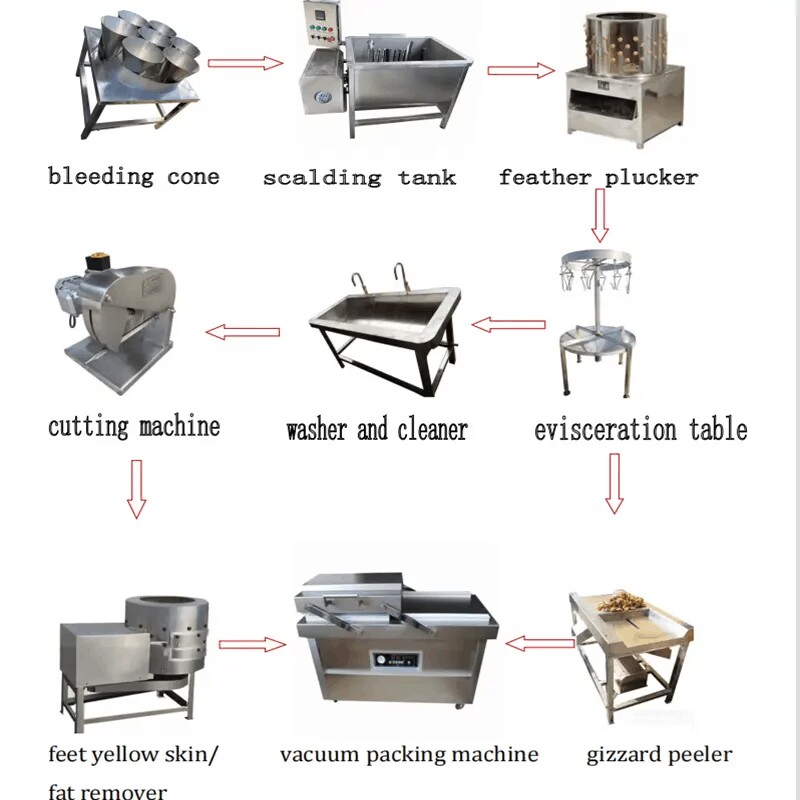

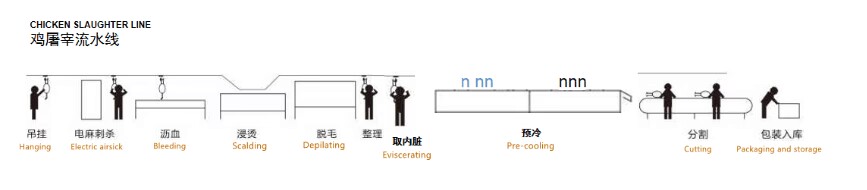

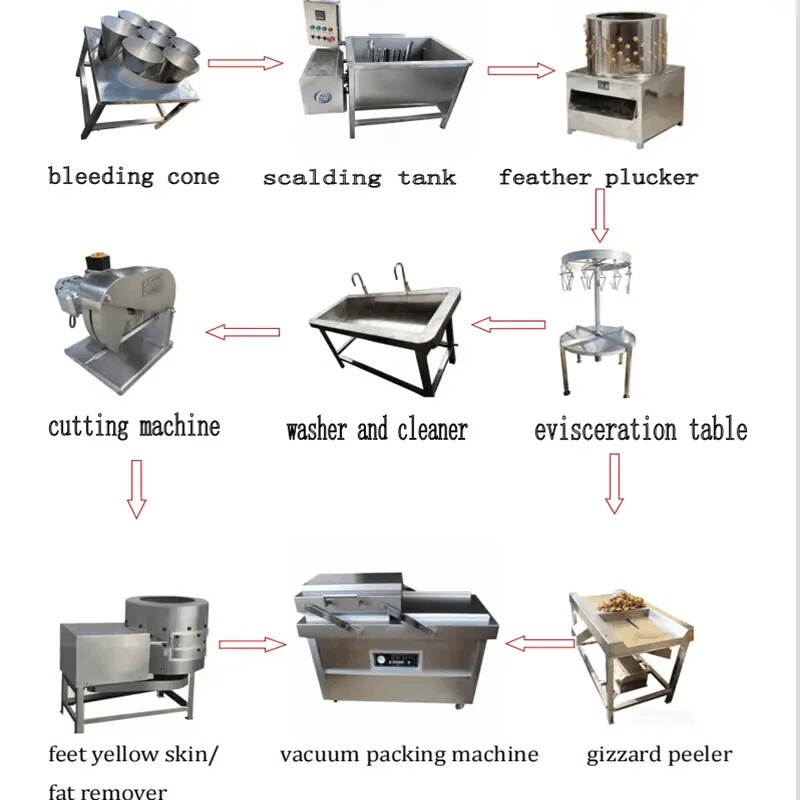

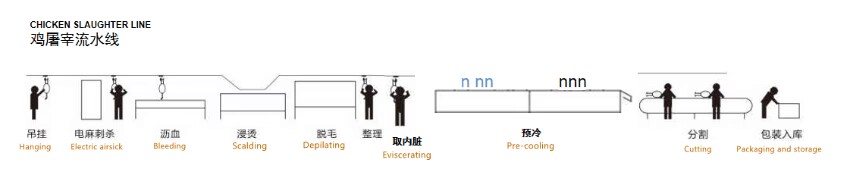

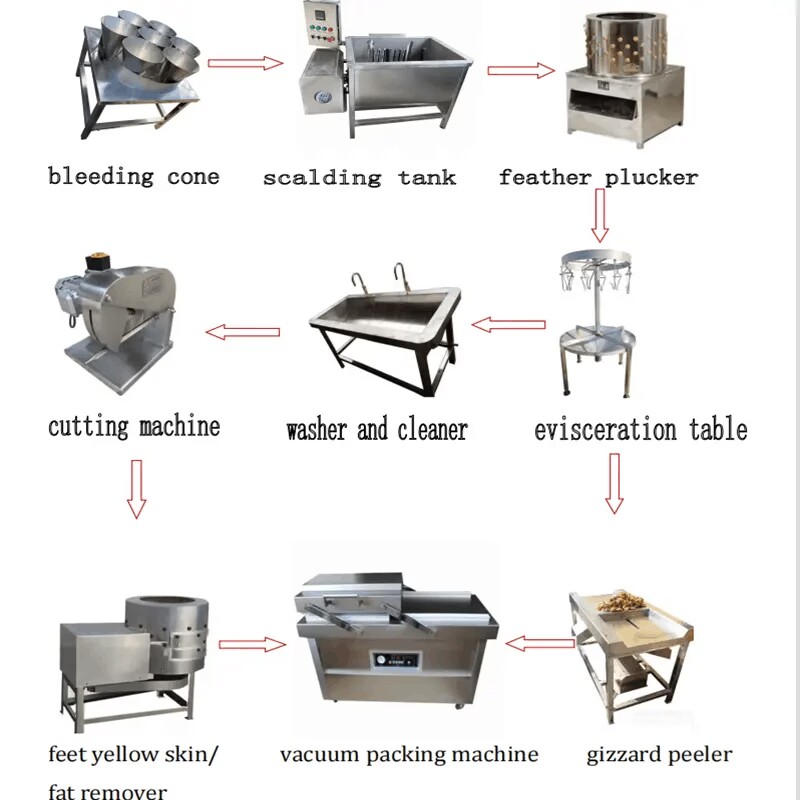

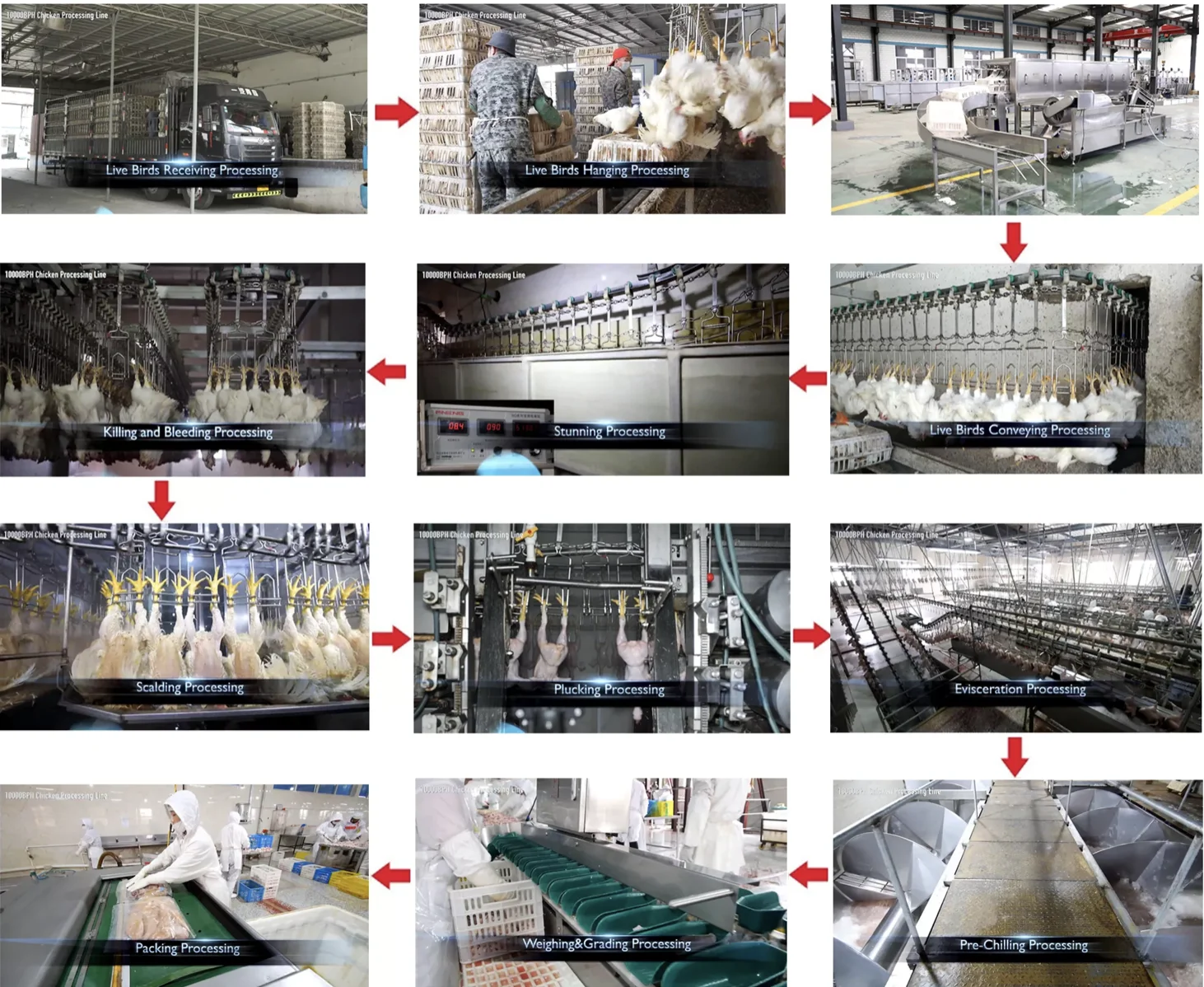

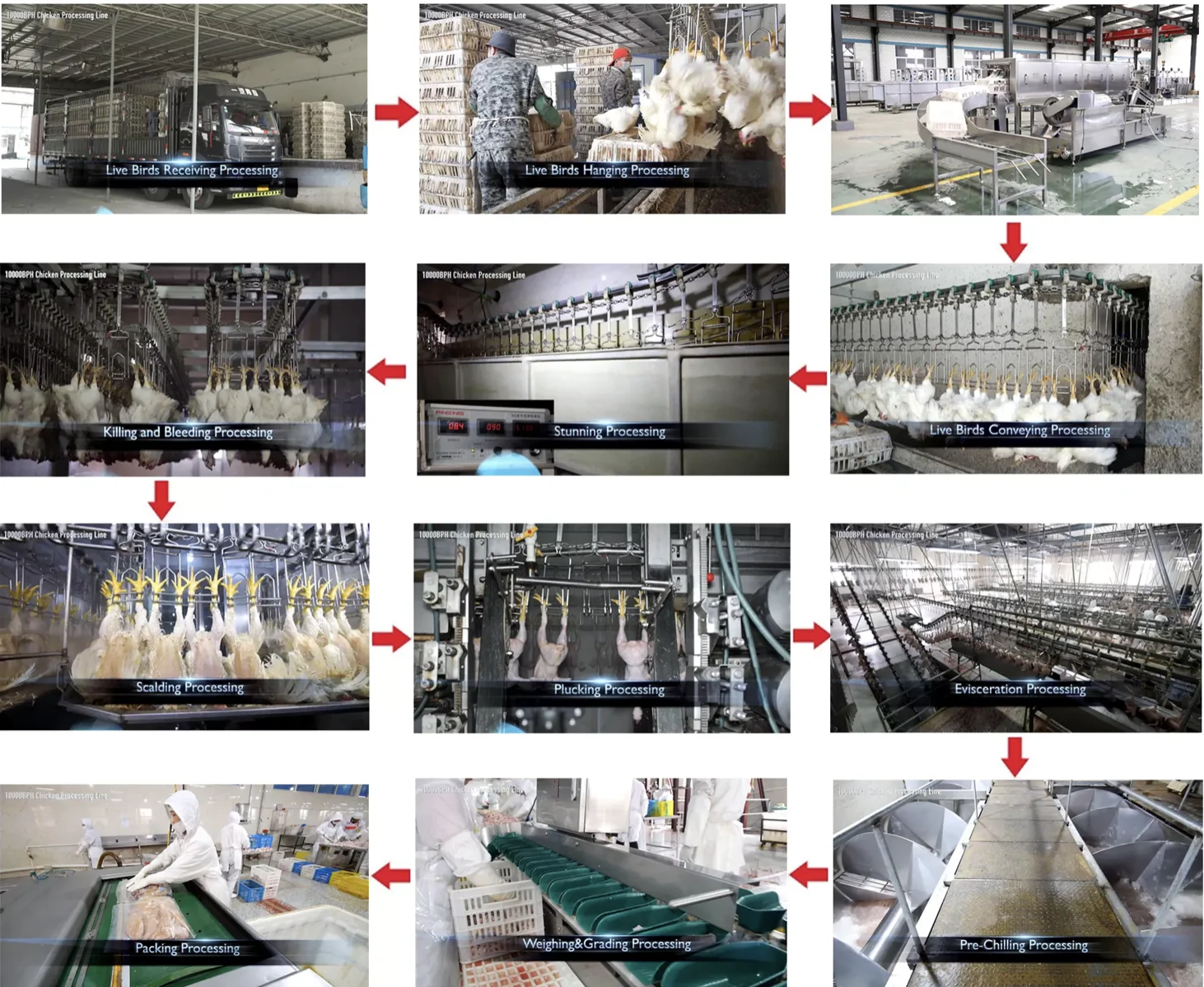

Procedure: killing, bleeding, scalding, plucking, eviscerating, chilling and packing

Complete Poultry processing line made of good quality, main material is SS 304 with imported Motor, Reducer.

Good stability with long use life, less maintenance.

|

Name |

Poultry Slaughter Machine |

|

Suit for |

Chicken Duck Goose Bird |

|

Usage |

Slaughtering Process |

|

Product name |

Poultry Slaughting Mechinery |

|

Processing |

Complete Slaughter Line |

|

Object |

Slaughterhouse Machine |

|

Feature |

Automatica |

|

Material |

304 Stainless Steel |

|

Capacity |

200-800BPH |

|

Advantage |

Easy Operation High Efficiency |

what is this product?

Application of Automatic slaughter equipment

Automatic slaughter equipment refers to machinery and systems designed to automate various stages of the slaughtering process in the meat industry. This equipment is used in abattoirs or slaughterhouses to increase efficiency, precision, and, in some cases, to improve animal welfare by minimizing stress during the slaughter process. The level of automation can vary depending on the specific type of equipment and the requirements of the slaughterhouse.

this product application.

How to choose layer cages for your poultry farm ?

Choosing automatic slaughter equipment for a poultry farm involves careful consideration of various factors to ensure efficient, humane, and compliant operations. Here's a guide to help you make informed decisions:

Slaughter Capacity:

Assess the daily slaughter capacity required for your poultry farm. Choose equipment that meets or exceeds the volume of birds you intend to process.

Type of Poultry:

Consider the type of poultry you raise (chickens, ducks, turkeys, etc.) as different species may require specific equipment tailored to their characteristics and sizes.

Stunning Method:

Evaluate the stunning method employed by the equipment. Options include electrical stunning, captive bolt stunning, or gas stunning. Consider the impact on animal welfare, as humane stunning methods are essential.

Bleeding and Scalding Systems:

Ensure the equipment includes efficient bleeding and scalding systems, especially if you're processing poultry that requires feather removal.

Evisceration Technology:

Choose evisceration equipment that is suitable for the type of poultry and meets hygiene standards. Look for systems that automate the removal of internal organs.

Carcass Washing and Chilling:

Check if the equipment includes systems for washing and chilling carcasses to ensure food safety and hygiene.

Conveyor Systems:

Assess the design and efficiency of conveyor systems for the smooth movement of poultry through different processing stages. A well-designed conveyor system enhances overall efficiency.

Quality Control Features:

Opt for equipment with built-in quality control features that monitor and ensure compliance with safety and hygiene standards.

Ease of Cleaning and Maintenance:

Choose equipment that is easy to clean and maintain. Hygiene is crucial in preventing contamination and ensuring the safety of the final products.

Compliance with Regulations:

Ensure that the automatic slaughter equipment complies with local and international regulations regarding animal welfare, hygiene, and food safety.

Customization Options:

Check if the equipment allows for customization to accommodate specific requirements of your poultry farm.

Training and Support:

Ensure that the supplier provides adequate training for your staff in operating and maintaining the equipment. Also, consider the level of customer support provided.

By carefully considering these factors, you can select automatic slaughter equipment that aligns with the specific needs and standards of your poultry farm, promoting efficient and humane poultry processing.