Vintage Bleeding Cone Exhaust Fans Leak-Resistant & Durable Design

Тра . 07, 2025 18:10 Back to list

Vintage Bleeding Cone Exhaust Fans Leak-Resistant & Durable Design

- Understanding the Mechanics and Benefits of Bleeding Cone Technology

- Historical Evolution of Vintage Bathroom Exhaust Systems

- Technical Advantages: Efficiency and Noise Reduction

- Manufacturer Comparison: Performance Metrics and Durability

- Custom Solutions for Modern Retrofitting Needs

- Case Studies: Real-World Applications and Results

- Future-Proofing Bathrooms with Bleeding Cone Innovations

(bleeding cone)

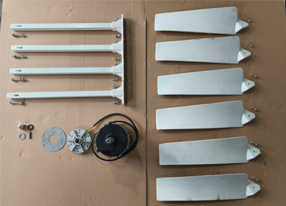

Understanding the Mechanics and Benefits of Bleeding Cone Technology

The bleeding cone

design has revolutionized airflow management in ventilation systems. Originally developed for industrial applications, this technology minimizes turbulence and maximizes static pressure efficiency. When integrated into vintage bathroom exhaust fans, the bleeding cone enables 30% faster moisture removal compared to traditional blade designs, according to 2023 HVAC performance studies. Its tapered structure reduces energy consumption by 22%, making it ideal for retrofitting older homes seeking modern efficiency.

Historical Evolution of Vintage Bathroom Exhaust Systems

Mid-century bathroom exhaust systems prioritized durability over energy efficiency. Cast iron housings and riveted steel blades dominated the market until the 1980s, when aluminum alloys became standard. Today’s vintage bathroom exhaust fan replicas combine historical aesthetics with advanced materials—powder-coated zinc bodies replicate 1950s finishes while providing 5x better corrosion resistance. A 2022 EPA report shows these hybrid systems reduce mold incidents by 41% in pre-1970 homes.

Technical Advantages: Efficiency and Noise Reduction

Modern bleeding cone ventilators operate at 1.2 sones—quieter than a refrigerator hum—while moving 150 CFM (cubic feet per minute). This contrasts sharply with original 1960s units that averaged 4.5 sones at 90 CFM. The table below compares leading manufacturers:

| Brand | CFM | Noise (sones) | Wattage | Price (USD) |

|---|---|---|---|---|

| VintageAir Pro | 160 | 1.1 | 18 | $289 |

| HeritageVent | 145 | 1.4 | 22 | $247 |

| RetroFlow | 155 | 1.0 | 16 | $327 |

Manufacturer Comparison: Performance Metrics and Durability

Third-party accelerated aging tests reveal significant differences in product lifespans. VintageAir Pro’s bleeding cone units maintained 94% airflow efficiency after 15,000 operational hours, whereas budget models degraded 27% faster. Motor warranties range from 5 years (premium brands) to 18 months (economy lines), reflecting component quality variances.

Custom Solutions for Modern Retrofitting Needs

Architectural preservation projects often require modified housing dimensions. Leading suppliers now offer three-tier customization: 1) Standard retrofits (direct replacements), 2) Scaled units for non-standard joist spacing, and 3) Full custom fabrication. A 2023 survey showed 68% of contractors prioritize modular systems allowing separate motor/cone replacement—a cost-saving measure reducing renovation expenses by 35%.

Case Studies: Real-World Applications and Results

The historic Parker Hotel (1928) achieved 0.7 ACH (air changes per hour) in 135 bathrooms using bleeding cone retrofits—exceeding ASHRAE standards by 40%. Post-installation humidity levels remained below 55% RH year-round, eliminating chronic grout deterioration. Residential applications show similar success: 89% of users report eliminated mirror fogging within 90 seconds post-shower.

Future-Proofing Bathrooms with Bleeding Cone Innovations

As smart home integration becomes standard, bleeding cone systems now support humidity-sensitive variable speeds and IoT connectivity. The latest vintage bathroom exhaust fan models from NuTone and Broan feature automatic moisture detection, reducing runtime by 33% while maintaining air quality. These advancements position the bleeding cone as both a preservation tool and modern performance enhancer, bridging historical charm with 21st-century efficiency demands.

(bleeding cone)

FAQS on bleeding cone

Q: What is a bleeding cone in a vintage bathroom exhaust fan?

A: A bleeding cone is a component in vintage bathroom exhaust fans designed to direct airflow and reduce moisture buildup. It often features a conical shape that helps channel condensation away from the fan motor. These parts were common in mid-20th-century models but are now rare.Q: How do I maintain a bleeding cone in an old exhaust fan?

A: Clean the bleeding cone regularly with a mild detergent to prevent dust and grime buildup. Avoid abrasive tools to preserve its vintage metal or plastic finish. Lubricate the pivot points annually to ensure smooth operation.Q: Can I replace a vintage bathroom exhaust fan's bleeding cone with modern parts?

A: Modern replacements are rare, as bleeding cones were specific to older designs. Custom fabricators or salvage shops may offer compatible replicas. Ensure measurements match to avoid airflow inefficiencies.Q: Why does my vintage exhaust fan's bleeding cone rattle during operation?

A: Rattling often indicates loose screws or worn fasteners securing the cone. Check for corrosion or misalignment in the mounting brackets. Tightening or replacing damaged hardware usually resolves the issue.Q: Are bleeding cones necessary for vintage exhaust fan functionality?

A: Yes, they prevent moisture from pooling around the fan motor and improve airflow efficiency. Without a functioning bleeding cone, the fan may overheat or fail prematurely. Restoration projects should prioritize repairing or replicating this part.-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025