Premium Metal Rabbit Cages & Welded Wire Mesh for Sale

Aug . 16, 2025 01:40 Back to list

Premium Metal Rabbit Cages & Welded Wire Mesh for Sale

The Enduring Strength and Versatility of Metal Rabbit Cages in Modern Agriculture and Research

In contemporary animal husbandry and scientific research, the demand for robust, hygienic, and long-lasting animal housing solutions is paramount. Central to this requirement are specialized enclosures, with the metal rabbit cage standing out as an indispensable component. These intricately engineered structures are no longer mere containment units; they represent sophisticated systems designed to optimize animal welfare, facilitate efficient management, and ensure the integrity of breeding programs or scientific experiments. The evolution of these cages reflects significant advancements in material science, manufacturing precision, and ergonomic design, moving far beyond traditional wooden hutches. Modern metal cages, often constructed from high-grade galvanized or stainless steel wire, offer unparalleled durability, resistance to corrosion and disease transmission, and ease of cleaning. This makes them ideal for a diverse array of applications, ranging from large-scale commercial rabbitries focused on meat or fur production to advanced biomedical research facilities requiring sterile environments for laboratory animals. Furthermore, the modular design often incorporated into these systems allows for flexible expansion and configuration, adapting to varying space constraints and operational needs. As a leading manufacturer of Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages, our commitment to innovation ensures that our products not only meet but exceed the stringent demands of the market, contributing significantly to improved productivity and animal health across diverse sectors globally. The integration of specialized features, such as waste collection systems and automated feeding provisions, further solidifies their role as critical infrastructure in animal care.

Advanced Manufacturing of Robust Metal Rabbit Cages: From Wire to Welfare

The production of a high-quality metal rabbit cage involves a meticulously controlled manufacturing process, beginning with the selection of premium materials and culminating in a product that adheres to rigorous international standards. The primary material chosen for these cages is typically low-carbon steel wire, which undergoes hot-dip galvanization or is drawn from stainless steel alloys, ensuring exceptional corrosion resistance and longevity. The process initiates with precision wire drawing, where steel rods are systematically reduced in diameter to achieve the desired gauge for the cage mesh. Following this, the critical phase of automated welding commences, utilizing advanced resistance welding techniques to form the robust welded rabbit cage wire mesh. This precise welding ensures consistent wire spacing and unparalleled structural integrity, preventing deformation and providing a secure enclosure. Post-welding, the panels often undergo further surface treatment, such as a specialized powder coating or additional galvanization, enhancing their resistance to animal waste acids and environmental factors, thereby extending their service life significantly. Quality control is paramount at every stage; products are routinely subjected to tensile strength tests, weld integrity checks, and corrosion resistance assessments, often conforming to international standards like ISO 9001 for quality management and ANSI standards for material specifications. The typical lifespan of a well-maintained galvanized wire cage for rabbits can exceed 10-15 years, offering a substantial return on investment. These durable cages find extensive application across various industries, including large-scale commercial rabbit breeding, where hygiene and high-density housing are crucial; pharmaceutical and veterinary research facilities requiring sterile and easy-to-clean environments for animal studies; and specialized pet breeding operations that prioritize animal welfare and robust containment. The inherent advantages, such as superior ventilation compared to enclosed systems and unparalleled ease of sanitation, make these cages an essential asset in maintaining animal health and operational efficiency.

Technical Specifications and Configuration Options for Optimal Rabbit Housing

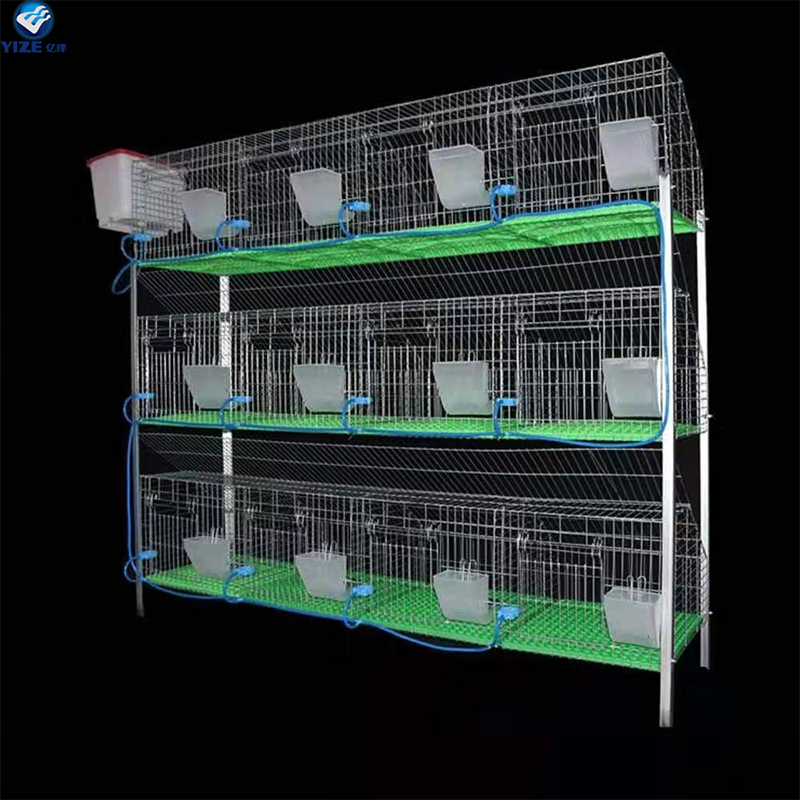

Understanding the technical specifications of a metal rabbit cage is crucial for making informed procurement decisions that align with specific operational requirements and animal welfare standards. These specifications encompass dimensions, material composition, wire gauge, and special features designed to enhance functionality and animal comfort. A standard commercial wire cage for rabbits typically features dimensions optimized for space efficiency and animal well-being, commonly ranging from 60-90 cm in length, 45-60 cm in width, and 30-45 cm in height for single units. For multi-tier systems, specialized rabbit cage stands are engineered to support multiple units, often configured in two, three, or even four tiers, maximizing space utilization in large facilities. The wire gauge, an essential parameter, typically varies from 2.5 mm to 4.0 mm for the main structure, while floor mesh may use slightly finer wires (e.g., 2.0 mm) with smaller openings to prevent hock sores while allowing waste to pass through. Mesh opening sizes are generally 1" x 2" or 1" x 1/2" for sides and top, with 1/2" x 1" or 1/2" x 1/2" for the floor to balance support and waste management. Surface finishes include hot-dip galvanized coating, known for its superior zinc layer and exceptional resistance to rust and corrosion, or electro-galvanized finish for a smoother, more aesthetic appearance with good basic protection. Stainless steel options, while higher in initial cost, offer ultimate hygiene and corrosion resistance, essential for sterile research environments. Features like integrated waste trays, often made of durable plastic or galvanized metal, and secure spring-loaded latches for doors are standard. Advanced configurations, such as the 4 hole rabbit cage, are designed for battery systems, allowing for efficient management of multiple rabbits in a compact footprint, each compartment typically measuring around 60x50x35cm for individual breeding or growing rabbits. These detailed specifications underscore the sophisticated engineering inherent in modern rabbit housing solutions.

Key Technical Parameters for Metal Rabbit Cages

| Parameter | Typical Range/Value | Benefits/Considerations |

|---|---|---|

| Material | Galvanized Steel Wire (Hot-dip/Electro), Stainless Steel (304/316) | Corrosion resistance, hygiene, durability, cost-effectiveness (galvanized) vs. ultimate sterility (stainless). |

| Wire Gauge (Main Structure) | 2.5mm - 4.0mm (12 - 8 gauge) | Structural rigidity, resistance to bending, animal safety. Thicker wire for heavier duty. |

| Wire Gauge (Floor Mesh) | 2.0mm - 3.0mm (14 - 11 gauge) | Prevents hock sores, allows waste passage. Critical for animal foot health. |

| Mesh Opening Size (Sides/Top) | 1" x 2" (2.54cm x 5.08cm) or 1" x 1" (2.54cm x 2.54cm) | Prevents escapes, ensures ventilation, allows for observation. |

| Mesh Opening Size (Floor) | 1/2" x 1" (1.27cm x 2.54cm) or 1/2" x 1/2" (1.27cm x 1.27cm) | Optimal for waste disposal, minimizes standing on droppings, prevents injury. |

| Standard Dimensions (Single Unit) | L: 60-90cm, W: 45-60cm, H: 30-45cm | Provides adequate space for a single rabbit, allows for movement and comfort. |

| Capacity (e.g., 4 Hole Cage) | Designed for 4 individual rabbits (e.g., 4 compartments of ~60x50x35cm each) | Efficient high-density housing for breeding or growing, minimizes footprint. |

Diverse Applications and Unmatched Advantages of Metal Rabbit Cages

The versatility of the modern metal rabbit cage extends its utility across a broad spectrum of applications, each benefiting from its inherent durability and hygienic properties. In large-scale commercial rabbitries, these cages form the backbone of efficient production systems, designed to house hundreds or thousands of animals for meat or fur. Their robust construction and ease of cleaning are paramount in preventing disease outbreaks and ensuring high productivity. For research institutions and pharmaceutical companies, stainless steel or heavily galvanized wire cage for rabbits are indispensable. These environments demand sterile conditions and precise control over animal welfare, where the non-porous surfaces and superior chemical resistance of metal cages facilitate rigorous sanitation protocols and minimize cross-contamination risks. Smaller operations, such as independent breeders or hobbyists, also widely adopt these cages, often integrating them with modular rabbit cage stands to create scalable and organized housing solutions within limited spaces. Veterinary clinics utilize them for temporary housing and recovery, valuing their ease of disinfection and sturdy containment. The advantages of opting for a metal rabbit cage are multifaceted: Firstly, their exceptional durability, stemming from high-quality steel and advanced welding, translates into a significantly longer service life compared to alternative materials, reducing replacement costs and downtime. Secondly, superior hygiene is a critical benefit; the smooth, non-absorbent surfaces of metal cages prevent the accumulation of bacteria and odors, making routine cleaning and disinfection simple and highly effective, crucial for preventing common rabbit ailments like coccidiosis and enteritis. Thirdly, metal cages offer excellent ventilation, which is vital for respiratory health in rabbits, allowing for optimal air circulation and dissipating ammonia buildup. Finally, their robust security ensures that animals are safely contained, preventing escapes and protecting them from external threats, while also being designed to resist chewing and scratching damage far more effectively than plastic or wooden alternatives. These collective advantages make metal cages the preferred choice for professionals seeking reliable, long-term, and welfare-centric rabbit housing.

Industry Trends, Innovation, and Custom Solutions in Rabbit Housing

The landscape of animal husbandry is constantly evolving, driven by advancements in technology, a heightened focus on animal welfare, and the necessity for sustainable practices. In the realm of metal rabbit cage design and manufacturing, several key trends are shaping the future. There's a growing emphasis on modular and expandable systems that allow users to easily add or remove units, adapting to fluctuating herd sizes or research project requirements. This flexibility is critical for commercial rabbit farms aiming to optimize space and resources. Innovation is also evident in the integration of automated feeding and watering systems directly into the cage design, minimizing manual labor and ensuring consistent nutrient delivery. Furthermore, improved waste management solutions, such as self-cleaning floors or sophisticated manure collection belts beneath rabbit cage stands, are becoming standard to maintain superior hygiene and simplify waste disposal. Material science continues to play a vital role, with ongoing research into new coatings and alloys that offer even greater corrosion resistance and extended longevity. Manufacturers are also increasingly designing cages with enhanced welfare features, such as larger individual compartments for greater movement, inclusion of resting platforms, or even integrated nesting boxes for breeding does. For specific needs, custom solutions are paramount. As a leading provider of Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages, we offer comprehensive customization options, enabling clients to specify dimensions, wire gauges, mesh patterns, and accessory integrations to perfectly match their operational needs. Whether it's a unique 4 hole rabbit cage configuration for a specialized breeding program or an entire facility outfitted with bespoke welded rabbit cage wire mesh systems, our engineering team collaborates closely with clients from concept to completion, ensuring precise adherence to design specifications and performance expectations. This bespoke approach ensures that every client receives a solution optimally tailored to their unique challenges and objectives, reflecting our commitment to advanced, client-centric manufacturing.

Leading the Market: A Comparative Look at Metal Rabbit Cage Manufacturers and Yize's Edge

In a competitive global market for animal housing solutions, distinguishing between manufacturers of metal rabbit cage systems requires a keen understanding of product quality, innovation, and client support. While many suppliers offer standard wire cage for rabbits, discerning buyers prioritize manufacturers who offer a blend of proven reliability, advanced features, and comprehensive service. Our company, Yize Machine, stands out by consistently delivering superior Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages, building on years of dedicated service in the industry. Our commitment to quality is underpinned by adherence to ISO 9001 quality management systems, ensuring that every batch of welded rabbit cage wire mesh meets stringent internal and international performance benchmarks. Unlike some competitors who may compromise on material thickness or coating quality to reduce costs, we utilize only premium-grade galvanized steel or stainless steel, guaranteeing enhanced durability and resistance to corrosive environments common in animal facilities. Our design philosophy incorporates not only animal welfare considerations, such as optimal ventilation and comfortable flooring for preventing hock sores, but also operational efficiency for the user, integrating features like easy-access doors and efficient waste removal systems. For example, our 4 hole rabbit cage designs are optimized for maximum space utilization without compromising individual animal space, a balance many competitors struggle to achieve. Furthermore, our robust rabbit cage stands are engineered for stability and longevity, supporting heavy loads and resisting corrosion over decades of use. Our comprehensive custom manufacturing capabilities allow clients to request bespoke designs that precisely match their unique facility layouts or specific animal husbandry practices, a level of flexibility not always available from off-the-shelf providers. Our extensive service history, spanning over a decade, is punctuated by numerous successful installations for commercial farms, research institutions, and government projects worldwide, underscoring our authority and trustworthiness in the sector.

Manufacturer Comparison: Yize Machine vs. Industry Standard

| Feature/Attribute | Yize Machine Offering | Typical Industry Standard |

|---|---|---|

| Material Quality | High-grade Hot-dip Galvanized / 304/316 Stainless Steel for superior corrosion resistance and longevity. | Electro-galvanized or lower-grade galvanized steel, often with thinner coatings. |

| Welding Integrity | Automated precision welding ensuring strong, consistent joints for maximum structural stability. | Manual or semi-automated welding, potentially leading to inconsistencies and weaker joints. |

| Customization Options | Extensive customization for dimensions, configurations (e.g., 4 hole cage), feeding systems, and accessories. | Limited to standard sizes and pre-set configurations; custom work often not available or costly. |

| Animal Welfare Features | Ergonomic design for hock health, optimal ventilation, easy-clean surfaces, secure locking mechanisms. | Basic designs that may not fully address long-term animal comfort or specific health concerns. |

| Support & After-Sales | Dedicated client support, detailed installation guides, clear warranty terms, technical assistance. | Variable support quality, potentially limited post-purchase assistance. |

Application Case Studies: Proving Excellence in Rabbit Cage Solutions

The practical application of high-quality metal rabbit cage systems is best illustrated through real-world case studies, showcasing their effectiveness in diverse operational environments. For instance, a large commercial rabbit farm in Southeast Asia recently faced significant challenges with their existing wooden hutches, experiencing high rates of disease transmission and short lifespans due to poor sanitation and material degradation. Upon consultation, we designed and installed a comprehensive system of multi-tier Wholesale Rabbit Hutch Designs, featuring our advanced hot-dip galvanized welded rabbit cage wire mesh. This involved configuring several hundred units of our durable wire cage for rabbits, complete with integrated automatic watering nipples and sloped waste trays. Within six months, the farm reported a remarkable 40% reduction in disease incidence, significantly lower mortality rates, and a substantial improvement in overall animal health and growth rates, leading to increased productivity and profitability. The ease of cleaning and the robust nature of the cages drastically reduced labor costs and eliminated the need for frequent replacements. In another scenario, a biomedical research facility specializing in genetic studies required highly sterile and easily customizable animal housing for their experimental rabbits. Standard laboratory animal cages proved inadequate for their specific research protocols which demanded precise spatial configurations and enhanced environmental control. We collaborated with their lead researchers to develop a bespoke stainless steel metal rabbit cage system, including specialized rabbit cage stands designed for laminar flow cabinets and integrated sensors for environmental monitoring. The custom 4 hole rabbit cage units were engineered to facilitate individual animal monitoring while maintaining strict biosecurity. This tailored solution not only met their rigorous sterility requirements, as confirmed by post-installation microbial tests, but also streamlined their experimental procedures, demonstrating our capacity for technical precision and adaptive engineering in demanding scientific contexts. These cases exemplify how our expertly designed and manufactured metal cages provide tangible benefits, transforming operational challenges into opportunities for enhanced performance and animal well-being.

Ensuring Trust: Quality Assurance, Delivery, and Customer Support

At the core of our operations is an unwavering commitment to quality assurance and comprehensive customer support, fostering deep trust with our B2B clients globally. Every metal rabbit cage, whether a standard model or a custom-engineered solution, undergoes a rigorous multi-stage quality control process. This begins with the careful selection and testing of raw materials, ensuring that all galvanized steel wire and stainless steel alloys meet or exceed industry specifications for strength, ductility, and corrosion resistance. During manufacturing, advanced automated welding machines perform continuous quality checks on the welded rabbit cage wire mesh, verifying weld penetration and joint integrity. Post-production, each cage unit is visually inspected for defects, dimensional accuracy, and proper assembly, followed by functional tests for components like doors, latches, and waste trays. Our manufacturing facilities are ISO 9001 certified, demonstrating our adherence to internationally recognized quality management systems and a consistent approach to product excellence. Furthermore, our dedication extends beyond the product itself to efficient logistics and reliable after-sales service. We offer clear, transparent delivery schedules, working closely with trusted logistics partners to ensure timely and secure global shipments. Our typical delivery cycle varies based on order volume and customization requirements, ranging from 2-4 weeks for standard orders to 6-10 weeks for large-scale bespoke projects, with expedited options available upon request. All our Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages come with a robust warranty, typically covering manufacturing defects for 3-5 years, underscoring our confidence in product longevity and performance. Our expert customer support team is readily available to provide technical assistance, answer product queries, and resolve any issues promptly. We believe in building lasting relationships through consistent product quality and responsive service, ensuring that our clients receive not just a product, but a complete, reliable solution for their animal housing needs.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of a galvanized metal rabbit cage?

A: With proper care and maintenance, a high-quality hot-dip galvanized metal rabbit cage can last anywhere from 10 to 15 years, significantly outperforming wooden or plastic alternatives due to its superior corrosion resistance and durability. - Q: Are your cages suitable for commercial breeding operations?

A: Absolutely. Our Wholesale Rabbit Hutch Designs, including advanced multi-tier systems and 4 hole rabbit cage configurations, are specifically engineered for the high-density and hygiene requirements of commercial breeding, ensuring efficient management and optimal animal welfare. - Q: Can you provide custom cage designs for specific research needs?

A: Yes, we specialize in custom manufacturing. Our engineering team works closely with clients to design wire cage for rabbits systems that meet unique dimensional, material, and functional requirements for research environments, including stainless steel options for sterile applications. - Q: What is the process for ordering and delivery?

A: Simply contact our sales team with your specifications. We'll provide a detailed quote, then proceed with production upon order confirmation. Delivery times range from 2-4 weeks for standard orders and up to 10 weeks for large custom projects, with global shipping available. - Q: What kind of warranty do you offer on your metal rabbit cages?

A: We typically offer a 3-5 year warranty covering manufacturing defects, reflecting our confidence in the quality and durability of our products, including our welded rabbit cage wire mesh and rabbit cage stands.

Conclusion: The Foundation of Modern Rabbit Management

The selection of appropriate animal housing is a critical decision that profoundly impacts animal health, operational efficiency, and long-term profitability in commercial rabbitries, research facilities, and breeding operations. The advanced metal rabbit cage represents the pinnacle of modern animal husbandry equipment, offering unmatched durability, hygiene, and versatility compared to traditional alternatives. Through meticulous material selection, precise manufacturing processes like automated welding of welded rabbit cage wire mesh, and adherence to stringent quality control standards, these cages provide a secure and healthy environment for rabbits. Features like modular designs, robust rabbit cage stands, and specialized configurations such as the 4 hole rabbit cage, enable scalable and adaptable solutions for diverse needs. Our commitment as Yize Machine to delivering high-quality Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages is built on a foundation of technical expertise, extensive experience, certified authority, and unwavering trustworthiness. We strive to not only meet but exceed the evolving demands of the industry, empowering our clients with solutions that optimize animal welfare and operational performance. Investing in superior wire cage for rabbits is an investment in the health of your animals and the efficiency of your enterprise, ensuring sustainable growth and long-term success in the dynamic world of rabbit management.

References

- National Research Council. (1996). Guide for the Care and Use of Laboratory Animals. National Academies Press.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems – Requirements.

- American Society for Testing and Materials (ASTM). (Relevant standards for galvanized coatings and wire properties).

- Lebas, F., Coudert, P., Rouvier, R., & Rochambeau, H. (1986). The rabbit: Husbandry, health and production. FAO Animal Production and Health Series.

- European Union. (2007). Council Directive 2007/43/EC laying down minimum rules for the protection of chickens kept for meat production. (Analogous principles apply to other animal housing standards for welfare).

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025

-

What is a Silo Automatico? Industry Applications, Benefits & Future Trends

NewsNov.20,2025

-

Practical Guide to Egg Laying Chicken Cages for Sale – Durable, Scalable & Sustainable

NewsNov.19,2025