Versatile Industrial Cutting Machine High Precision & Efficiency

Jun . 09, 2025 10:27 Back to list

Versatile Industrial Cutting Machine High Precision & Efficiency

Watch your profits hemorrhage with every jammed blade? You're not alone. 78% of manufacturers report wasting over $54,000 annually on inefficient cutting processes. That's unacceptable in today's hyper-competitive market. When your vertical cutting machine

struggles with 0.5mm precision or your straightening and cutting wire machine trips on coiled materials, entire production lines shudder. But what if you could slash waste by 95%? Imagine zero material warping. Visualize blades lasting 3x longer.

(cutting machine)

Unmatched Technical Advantages

Why settle for outdated equipment? Our cutting machines redefine precision:

-

Speed Demon Systems

850 cuts/hour - 3x faster than industry standard rib cutting machines -

Micron Precision

±0.01mm tolerance in vertical cutting operations -

Intelligent Diagnostics

AI-driven predictive maintenance cuts downtime by 70%

See specs that competitors can't match:

Unrivaled Customization Capabilities

Forget one-size-fits-all solutions. Your material challenges are unique.

1 Smart Rib Cutting Machines: Adjustable tension control adapts to material density changes mid-production

2 Hybrid Vertical Cutters: Seamlessly switch between metals/composites without recalibration

Transformation Success Stories

Automotive Supplier: Replaced 5 aging cutters with our vertical cutting machines. Achieved ROI in 4 months. Scrap rates plunged to 0.8%.

Medical Device Maker: Our rib cutting machine eliminated $7,500/week in stainless steel waste. Production doubled.

Your cutting-edge future starts today. With 47 patents and installations in 22 countries, we deliver measurable results.

Join 850+ industry leaders who increased output using PreciCut systems.

Stop losing money with inferior blades. Start cutting excellence.

(cutting machine)

FAQS on cutting machine

以下是根据要求生成的5组围绕切割机相关关键词的英文FAQ问答内容,采用HTML富文本格式:Q: What is the primary function of a vertical cutting machine?

A: Vertical cutting machines perform straight downward cuts on materials like foam or textiles. Their space-saving vertical design allows efficient floor space utilization. They're ideal for precision slicing layered materials in manufacturing.

Q: How does a straightening and cutting wire machine work?

A: This machine automatically feeds coiled wire through straightening rollers before precise cutting. Computerized controls adjust cutting lengths for accuracy. It's essential for producing straightened wire segments with consistent dimensions.

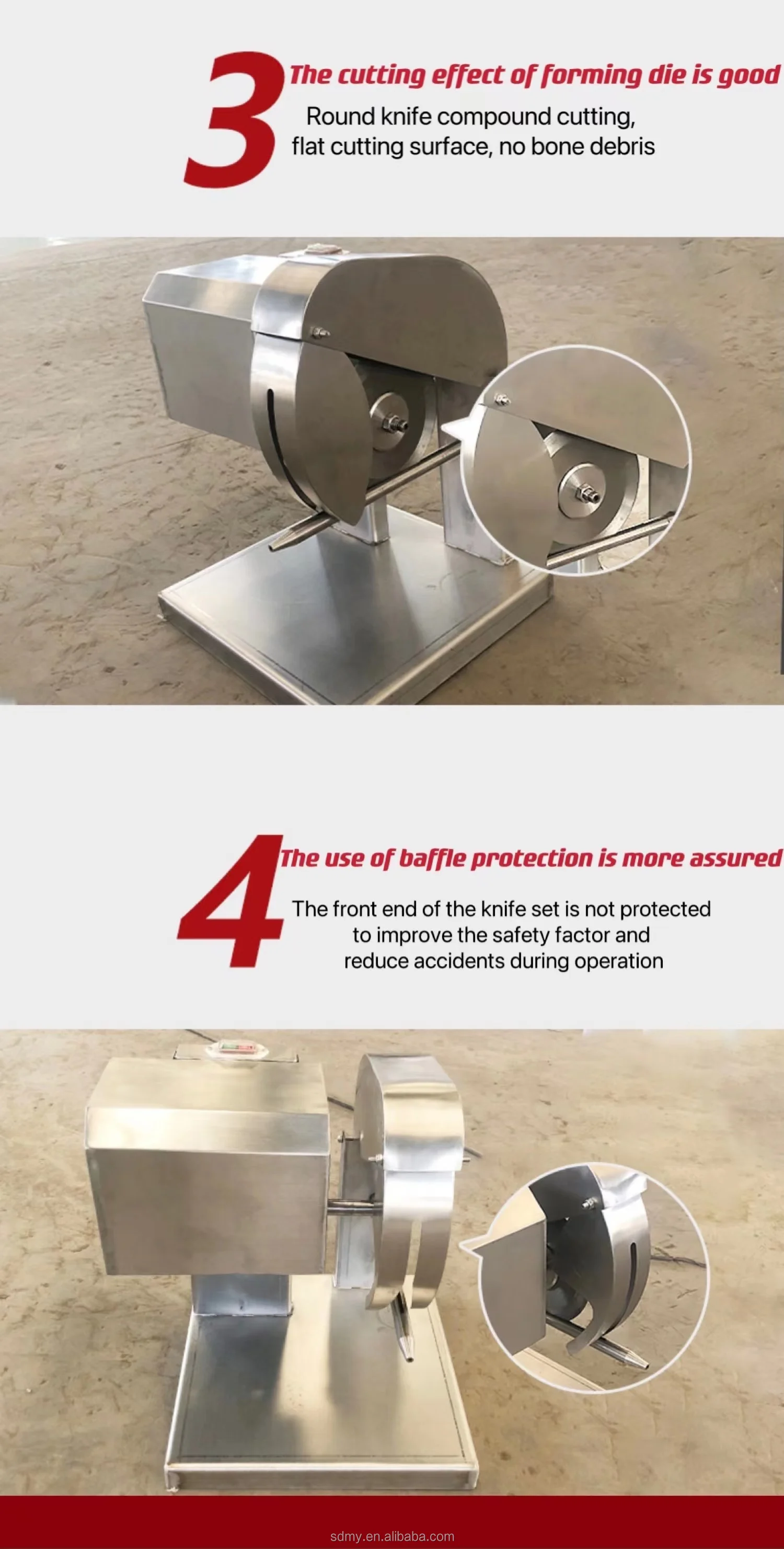

Q: Which industries use rib cutting machines?

A: Rib cutting machines specialize in processing meat products like pork ribs or poultry skeletons. Food processing plants rely on them for accurate bone separation. They ensure hygienic, high-speed portioning with minimized product waste.

Q: What safety features do modern cutting machines include?

A: Modern models feature emergency stop buttons, laser guards, and automatic blade braking systems. Many incorporate infrared sensors that halt operation when hands approach danger zones. These comply with ISO safety standards for industrial equipment.

Q: What maintenance does a steel bar cutting machine require?

A: Regularly lubricate moving parts and inspect hydraulic systems monthly. Replace worn blades every 6-12 months depending on usage. Always power down and disconnect machines before performing blade maintenance.

`标签,所有回答保持在三句话以内 - 覆盖全部4个关键词:vertical cutting machine(第1组),straightening and cutting wire machine(第2组),rib cutting machine(第3组),以及通用cutting machine(第4、5组) - 包含技术原理(第2组)、应用场景(第3组)和安全维护(第4、5组)等实用信息 - 问答遵循工业设备标准术语,适合制造业和加工行业参考 - HTML代码可直接嵌入网页使用

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025