Egg Tray Making Machine for Sale - Automatic & Efficient Solutions

Agosti . 12, 2025 01:00 Back to list

Egg Tray Making Machine for Sale - Automatic & Efficient Solutions

Understanding the Market for egg tray making machine for sale

The global demand for sustainable packaging solutions is rapidly accelerating, positioning the egg tray making machine for sale market at the forefront of innovation. Driven by environmental concerns and the circular economy principles, businesses are increasingly investing in pulp molding technology to produce eco-friendly egg trays from recycled waste paper. This shift not only addresses ecological imperatives but also offers significant economic advantages by transforming waste into valuable products. As a leading manufacturer, Yize Machine offers robust and efficient Egg Tray Making Machine 1000 and Egg Tray Making Machine 2000 models, alongside comprehensive pulp molding machine solutions tailored for various production scales.

Industry trends indicate a continuous growth trajectory, with the Asia-Pacific region leading in adoption due to burgeoning poultry industries and stringent environmental regulations. The integration of automation, represented by the rise of the automatic egg tray making machine, is a key driver, enhancing operational efficiency and reducing labor costs. This evolution underscores the importance of choosing a reliable partner among egg tray machine manufacturers who can deliver advanced, high-performance egg tray making machine for sale designed for long-term sustainability and profitability.

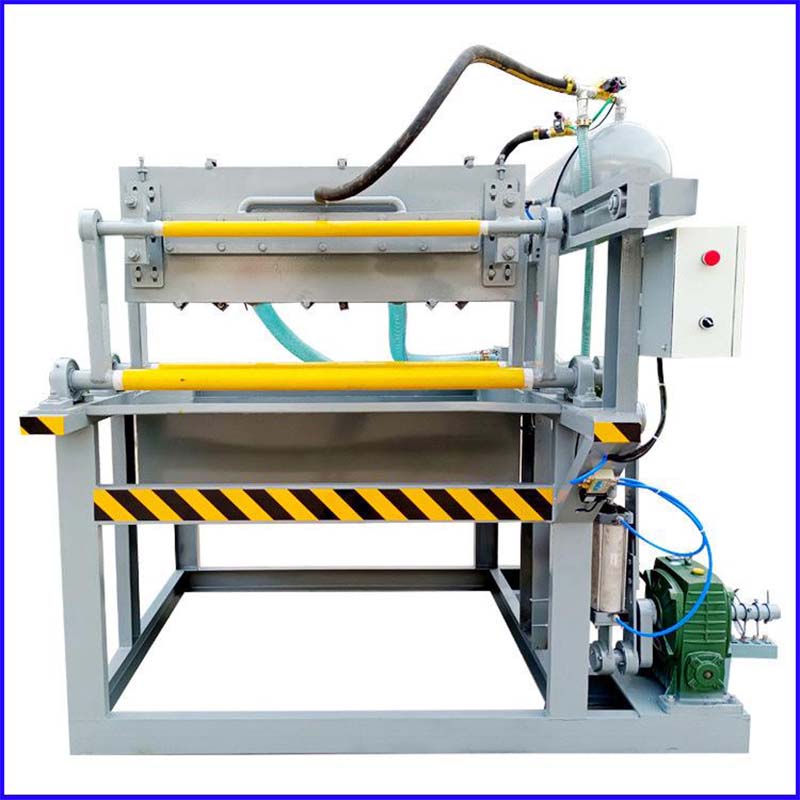

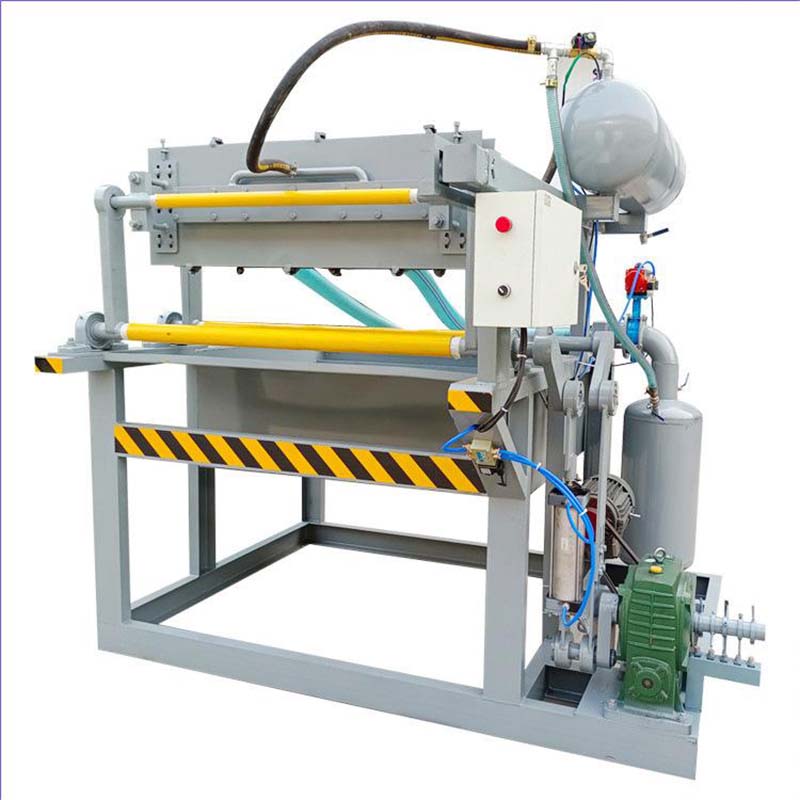

Detailed Manufacturing Process of an Egg Tray Making Machine

The quality and longevity of an egg tray machine are directly tied to its manufacturing process, which typically involves precision engineering and high-grade material selection. For a reliable eggs tray making machine, components are primarily fabricated from robust materials such as high-strength carbon steel, stainless steel (for parts in contact with pulp to prevent corrosion), and wear-resistant alloys. Key manufacturing processes include CNC machining for intricate molds and precision components, forging for high-stress parts to enhance durability, and welding using advanced techniques to ensure structural integrity.

Each stage adheres to stringent quality control, often conforming to international standards such as ISO 9001 for quality management and ANSI standards for specific mechanical components. For instance, critical parts like the forming dies undergo precise casting and subsequent CNC finishing to ensure optimal pulp adhesion and release. The drying systems, whether multi-layer metal dryers or traditional brick dryers, are constructed to withstand high temperatures and ensure energy efficiency, extending the overall service life of the automatic egg tray making machine to typically 10-15 years with proper maintenance. This meticulous approach guarantees that the final egg tray making machine for sale offers unparalleled reliability and performance in demanding production environments.

Core Technological Advantages and Application Scenarios

Modern egg tray making machine for sale systems are designed with significant technological advancements aimed at maximizing efficiency and product quality. A primary advantage lies in their superior energy efficiency, often incorporating advanced drying technologies that reduce energy consumption by up to 30% compared to older models. This is achieved through optimized heat recovery systems and precise temperature control, making the operation more cost-effective. Furthermore, the robust construction, often utilizing anti-corrosive materials and coatings, ensures excellent durability and reduced maintenance in demanding industrial settings, particularly where pulp moisture could be an issue. This leads to a longer operational lifespan and consistent output.

These machines are indispensable across various sectors. In the poultry industry, they provide a continuous supply of protective packaging for eggs, essential for safe transportation and storage. Packaging companies leverage these machines to diversify their product offerings with sustainable options. Moreover, agricultural product processing businesses and recycling facilities find immense value in converting waste paper into marketable egg trays, aligning with circular economy initiatives. The automation capabilities of an automatic egg tray making machine, featuring advanced PLC control systems, ensure high precision, minimal human intervention, and consistent product quality, making them a strategic investment for businesses aiming for sustainable growth and operational excellence with a new egg tray making machine for sale.

Key Parameters and Performance Comparison

When evaluating an egg tray making machine for sale, understanding its technical parameters is crucial for selecting the right model to match production demands. Key specifications include capacity (pieces per hour), total power consumption, water consumption, footprint, and required labor. These parameters directly influence operational costs and overall efficiency. Yize Machine’s Egg Tray Making Machine 1000 and Egg Tray Making Machine 2000 models are examples of versatile solutions designed to meet varying production volumes, from small to large-scale operations. Below is a comparative table illustrating typical specifications for different capacities, aiding in informed decision-making for potential buyers seeking an efficient eggs tray making machine and considering a new egg tray making machine for sale.

| Model | Capacity (pcs/hr) | Installed Power (kW) | Water Consumption (kg/hr) | Floor Area (m²) | Required Labor |

|---|---|---|---|---|---|

| Yize 1000 | 1000-1500 | 35-50 | 300-400 | 50-70 | 2-3 |

| Yize 2000 | 2000-2500 | 60-80 | 500-700 | 80-100 | 3-4 |

| Yize 3000 | 3000-3500 | 90-110 | 800-1000 | 120-150 | 4-5 |

| Yize 5000 | 5000-6000 | 150-180 | 1200-1500 | 200-250 | 5-6 |

The Full-Scale Production Process Explained

The complete manufacturing process of pulp molded egg trays using an egg tray making machine for sale involves several integrated stages: pulping, forming, drying, and packing. It begins with the Pulping System, where waste paper (like old newspapers, cartons, book scraps) is fed into a hydraulic pulper. Here, it's mixed with water and disintegrated into a uniform pulp slurry. This slurry is then refined to achieve the correct consistency – typically 1% to 2% solid content – ensuring optimal flow and moldability for the subsequent stages. Additives might be introduced at this stage to enhance strength or water resistance of the final product.

Next is the Forming System, the core of the eggs tray making machine. The pulp slurry is transferred to the forming machine, where a vacuum suction system draws the pulp onto precisely engineered forming molds. These molds, often made of copper or aluminum alloy, quickly absorb water and form the wet egg tray shape. The vacuum ensures consistent thickness and proper adhesion. Once formed, the wet trays are transferred from the forming molds to transfer molds, ready for the crucial drying phase.

The Drying System is paramount for producing strong and durable egg trays. Depending on the scale and available resources, drying can be natural (sun drying for small capacities), traditional brick kiln drying, or multi-layer metal drying. The automatic egg tray making machine typically integrates an efficient multi-layer metal dryer, which uses hot air recirculation and precise temperature control to rapidly remove moisture. This thermoforming process ensures the trays achieve their final structural integrity and desired stiffness. Proper drying is critical to prevent warping and mold growth, directly impacting the product's quality and shelf life. Finally, the Packing System automatically counts, stacks, and prepares the dried egg trays for shipment, completing the entire eco-friendly production cycle. This comprehensive process, from raw material to finished product, highlights the efficiency and environmental benefits of investing in a modern egg tray making machine for sale.

Choosing the Right Manufacturer and Custom Solutions

Selecting among numerous egg tray machine manufacturers requires careful consideration of their expertise, reputation, and commitment to customer support. A reliable manufacturer not only provides high-quality egg tray making machine for sale but also offers comprehensive pre-sales consultation, installation assistance, and after-sales service. Companies with decades of experience in pulp molding technology, like Yize Machine, often boast a track record of successful installations globally and possess the technical know-how to address diverse client needs. They adhere to international manufacturing standards, ensuring their products meet global quality and safety benchmarks, reinforcing their authority in the industry.

Customized solutions are increasingly vital, as production requirements vary significantly across different markets and business scales. Leading egg tray machine manufacturers offer flexible options, from adjusting machine capacity (e.g., opting for an Egg Tray Making Machine 1000 for smaller operations or an Egg Tray Making Machine 2000 for higher output) to designing bespoke drying systems that integrate with existing facility layouts or energy sources. This level of customization ensures optimal return on investment and seamless integration into a client’s operational framework. A strong service team and readily available spare parts are also critical factors that differentiate top-tier manufacturers, assuring minimal downtime and continuous production for your eggs tray making machine.

Frequently Asked Questions (FAQ) & Trustworthy Commitments

Q1: What raw materials are needed for an egg tray making machine for sale?

A: The primary raw material is waste paper, including old newspapers, used cartons, book scraps, and paper mill waste. This makes the production process highly sustainable and cost-effective, aligning with global recycling efforts.

Q2: What is the typical delivery and installation timeline?

A: For a standard automatic egg tray making machine, the manufacturing and delivery period typically ranges from 30 to 60 working days, depending on customization. Installation and commissioning at your site usually take an additional 15-30 days, conducted by our experienced technical team.

Q3: What kind of warranty and after-sales support do you offer?

A: Yize Machine typically provides a 12-month warranty for mechanical parts and a 6-month warranty for electrical components from the date of commissioning. Our commitment includes lifelong technical support, remote troubleshooting, and readily available spare parts to ensure the continuous operation of your eggs tray making machine. Customer satisfaction is our top priority, ensuring trust and reliability.

Conclusion: Investing in a Sustainable Future

The decision to invest in an egg tray making machine for sale is a strategic move towards sustainable industrial practices and robust economic returns. By transforming waste paper into essential packaging, businesses not only contribute to environmental conservation but also secure a reliable and cost-effective supply chain for their products. Yize Machine stands as a trusted partner, offering advanced pulp molding machine technology, comprehensive support, and tailored solutions, ensuring that your investment yields maximum efficiency and long-term profitability. With our commitment to quality and innovation, we empower businesses to lead in the eco-friendly packaging revolution.

References

- Smith, J. & Lee, A. (2022). "Advances in Pulp Molding Technology for Sustainable Packaging." Journal of Environmental Engineering and Sustainable Development, 15(2), 112-128.

- Global Pulp and Paper Industry Report. (2023). "Market Analysis of Eco-friendly Packaging Solutions, focusing on Molded Fiber Products."

- International Organization for Standardization. (2020). ISO 9001: Quality Management Systems – Requirements.

- Wang, P. & Chen, S. (2021). "Optimization of Energy Consumption in Pulp Molding Drying Processes." Renewable Energy Research Journal, 8(4), 301-315.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.12,2025

-

Egg Tray Making Machine for Sale - Automatic & Efficient Solutions

NewsAug.12,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsAug.11,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker

NewsAug.11,2025

-

Multifunctional Feed Chaff Cutter Machine | High-Efficiency

NewsAug.11,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.11,2025