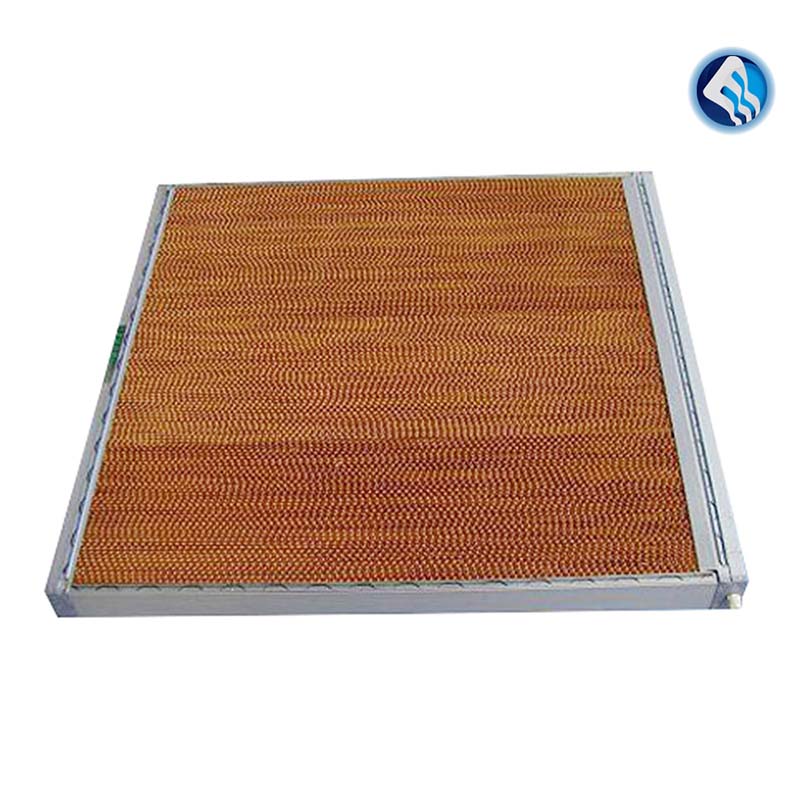

Greenhouse Evaporative Cooling Pads: Efficient & Durable

Oct . 21, 2025 11:30 Back to list

Greenhouse Evaporative Cooling Pads: Efficient & Durable

Are Greenhouse Evaporative Cooling Pads Still the Smart Play? A Field Note from the Grow Room

If you’ve walked a commercial tomato house in July, you already know the soundtrack: fans humming, a sweet tang of wet cellulose, and crops not just surviving—thriving. That’s the promise of Greenhouse Evaporative Cooling Pads, and, to be honest, they’re having a moment again as energy prices seesaw and growers look for low-lift cooling.

Why the renewed interest

Three things: energy math, climate volatility, and better media. Modern pads use corrugated cellulose with spatial cross-linking resins—high absorbency, fast pervasion, and decent mildew resistance. The unit I examined in Hebei (origin: Jinwang Western Street, Industrial Zone, Anping County, Hengshui, China) kept showing 75–85% saturation efficiency under clean-water conditions. Not bad; actually, impressive for the price bracket.

Technical snapshot

Many customers say the water uptake is the clincher. This media diffuses one drop in ≈4–5 s; capillary rise hits 60–70 mm/5 min and around 200 mm/1.5 h, which aligns with international benchmarks. Cooling efficiency can reach ≈80% with proper air velocity and distribution. Galvanized or optional aluminum panels help with corrosion, which—speaking candidly—is where cheap frames die first.

| Spec | Typical Value (≈, real-world may vary) |

|---|---|

| Media type | Corrugated cellulose, cross-linked resin, phenol-free |

| Flute angles | 45×45 or 45×15 |

| Thickness/Height/Depth | 100–200 mm / up to 2000 mm / 300–600 mm |

| Saturation efficiency | 75–85% @ 1.5–2.0 m/s face velocity |

| Water distribution | Top-feed, recirculating pump, inline filtration |

| Frame | Galvanized steel or optional aluminum |

| Service life | 3–5 seasons poultry; 5–8 years greenhouse with treated water |

Process flow and testing

- Materials: high-porosity kraft cellulose, cross-linking resins, galvanized/aluminum frames.

- Methods: spatial crossing corrugation, heat-set curing, precision lamination.

- Testing: water absorption (Cobb/TAPPI-style), capillary rise timing, salt-spray on frames (ASTM B117), bio-growth checks, airflow/pressure drop per ASHRAE Handbook methods.

- Certifications: ISO 9001 factory QA; material is phenol-free; RoHS/REACH statements available on request.

In practice, Greenhouse Evaporative Cooling Pads pair with exhaust-fan walls. Target ΔT is often 6–12°C depending on wet-bulb depression; humidity rise is the known trade-off (manageable with staging and night purges).

Where they shine

- Greenhouses (leafy greens, tomatoes, flowers). - Poultry and livestock barns. - Mushroom houses, nurseries, even light industrial workshops that can tolerate higher RH. Many operators report 20–40% power savings against DX cooling in shoulder seasons.

Vendor landscape (quick take)

| Vendor | Lead time | Certs | Price level | Notes |

|---|---|---|---|---|

| YIZE Machine (Hebei) | ≈ 10–20 days | ISO 9001; RoHS/REACH on request | $$ (competitive) | Strong water uptake; galvanized/aluminum options |

| Vendor A (EU) | ≈ 3–6 weeks | ISO 9001/14001 | $$$ | Premium frames; higher freight for export |

| Vendor B (Local) | ≈ 7–14 days | Varies | $–$$ | Easy service; mixed media consistency |

Customization and install tips

Custom heights/depths, 45×15 flute for higher pressure drops (but often higher efficiency), corrosion class upgrades, and integrated top distributors. Pro tip: filter the sump, dose biocide sparingly, and maintain 1.5–2.0 m/s face velocity. It seems simple—and it is—but water quality is destiny here.

Mini case study

A 2,000 m² tomato greenhouse in a semi-arid belt swapped legacy pads for Greenhouse Evaporative Cooling Pads (200 mm depth, galvanized frame). Result: inlet air drop 8–11°C at peak sun, fan energy down ≈28% vs. previous season, and better uniformity (2.3°C max bay-to-bay delta). Feedback was candid—“less slime, fewer clogs”—after they added a 200-micron inline filter.

Standards to keep in mind

Design to ASHRAE evaporative cooling guidance; consider ASHRAE 55 for comfort envelopes (for retail greenhouses), and ISO 9001 for manufacturer QA. Agricultural readers often reference FAO and ASABE greenhouse climate notes for airflow and pad-fan sizing.

References

[1] ASHRAE Handbook—HVAC Systems and Equipment, Evaporative Air-Cooling Chapter.

[2] FAO: Greenhouse climate control—Evaporative cooling fundamentals.

[3] ASTM B117—Standard Practice for Operating Salt Spray (Fog) Apparatus (frame corrosion).

[4] ISO 9001—Quality management systems (manufacturer QA).

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025