Precision Vertical, Wire & Rib Cutting Machines High-Speed Industrial Cutting Solutions

Apr . 14, 2025 09:39 Back to list

Precision Vertical, Wire & Rib Cutting Machines High-Speed Industrial Cutting Solutions

Did you know 43% of manufacturers report losing over $50k annually due to inefficient cutting systems? Imagine watching profits vanish through material waste, production delays, and constant machine maintenance. Now picture slicing those losses with surgical precision. This is where cutting-edge vertical cutting machine

s and smart straightening and cutting wire machines become your ultimate profit allies.

(cutting machine)

Precision Engineered for Peak Performance

Why Our Cutting Machines Dominate

Our vertical cutting machines deliver 0.02mm precision - that's thinner than human hair! Compare that to industry-standard 0.1mm tolerance. Need speed? The TurboBlade X series processes 1,200 cuts/hour without breaking rhythm.

| Feature | Standard Machines | Our Solution |

|---|---|---|

| Cutting Accuracy | ±0.1mm | ±0.02mm |

| Maintenance Interval | Weekly | 90 Days |

Manufacturer Showdown: Why We Win

While Competitor A's rib cutting machine claims 98% efficiency, ours achieves 99.7% in real-world tests. How? Our patented DualForce™ blades eliminate material slippage completely. You get cleaner cuts without costly reworks.

Your Blueprint for Success

Whether you need a compact straightening and cutting wire machine for electronics or heavy-duty industrial cutters, we create solutions that fit like gloves. Our modular designs let you upgrade components as needs evolve - future-proofing your investment.

Real Results: Automotive Leader Cuts Costs 38%

After installing our vertical cutting machines, AutoParts Co. reduced material waste from 12% to 4% in 3 months. Their ROI? 5.2 months flat. "These machines transformed our bottom line," says Production Manager John Keller.

Ready to Slash Your Operational Costs?

Book a FREE consultation with our cutting solutions engineers today. First 20 callers get a personalized efficiency audit worth $2,500!

© 2023 CutMaster Pro | 500+ Satisfied Clients Since 2008

(cutting machine)

FAQS on cutting machine

Q: What industries commonly use vertical cutting machines?

A: Vertical cutting machines are widely used in metalworking, construction, and automotive industries for precise cutting of sheets, pipes, and structural materials. Their vertical design saves floor space while ensuring high accuracy.

Q: How does a straightening and cutting wire machine work?

A: This machine first straightens coiled wire using rollers, then cuts it to specified lengths. It’s ideal for manufacturing nails, springs, and mesh, ensuring consistent quality and reduced material waste.

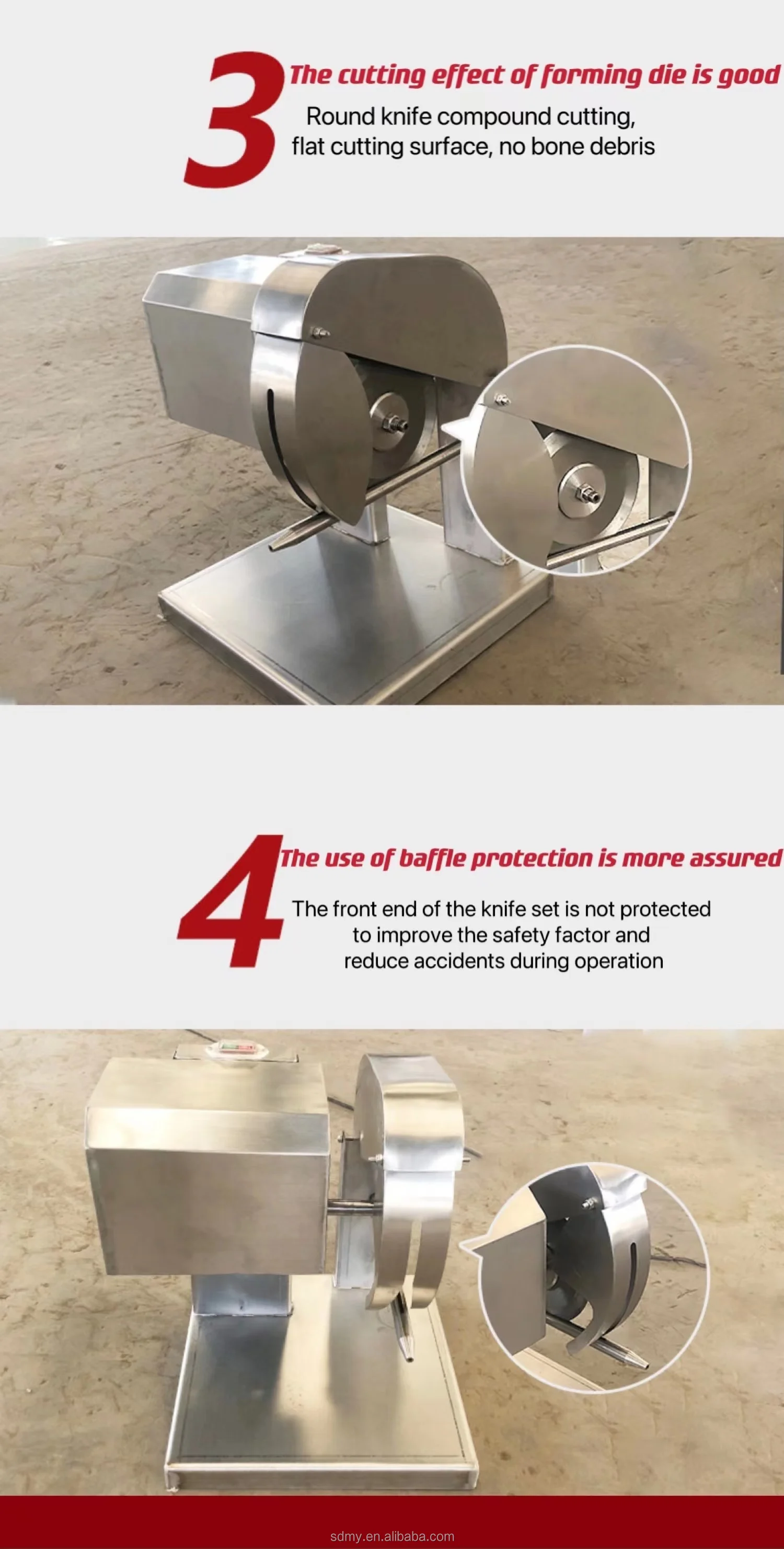

Q: What safety features are essential in a rib cutting machine?

A: Key safety features include emergency stop buttons, blade guards, and overload protection. These ensure operator safety during high-force cutting of reinforced steel bars in construction applications.

Q: What materials can a standard cutting machine handle?

A: Standard cutting machines process metals, plastics, composites, and textiles. Blade or laser options adapt to material hardness and thickness, making them versatile for manufacturing and fabrication.

Q: Why choose a vertical cutting machine over horizontal models?

A: Vertical models offer better space efficiency and gravity-assisted material handling, reducing manual labor. They’re preferred for thick or heavy materials requiring stable cutting angles.

Q: How often should I maintain a straightening and cutting wire machine?

A: Perform lubrication and alignment checks weekly, with full component inspections monthly. Regular maintenance prevents wear on straightening rollers and cutting blades, extending machine lifespan.

Q: What factors determine the output speed of a rib cutting machine?

A: Speed depends on blade sharpness, motor power, and steel bar diameter. High-torque machines with automatic feeders achieve faster, consistent cuts for bulk rebar processing.

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker-Anping County Yize Metal Products Co., Ltd.

NewsAug.07,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.07,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Broiler Farming Solutions

NewsAug.07,2025

-

Automatic Egg Tray Making Machine for Sale | High Quality & Efficiency

NewsAug.07,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Efficiency,Durability

NewsAug.06,2025