Automatic Drinking Line: Efficient, Hygienic Livestock Hydration

Aug . 23, 2025 01:40 Back to list

Automatic Drinking Line: Efficient, Hygienic Livestock Hydration

Strategic Implementation of Advanced Automatic Drinking Line Systems

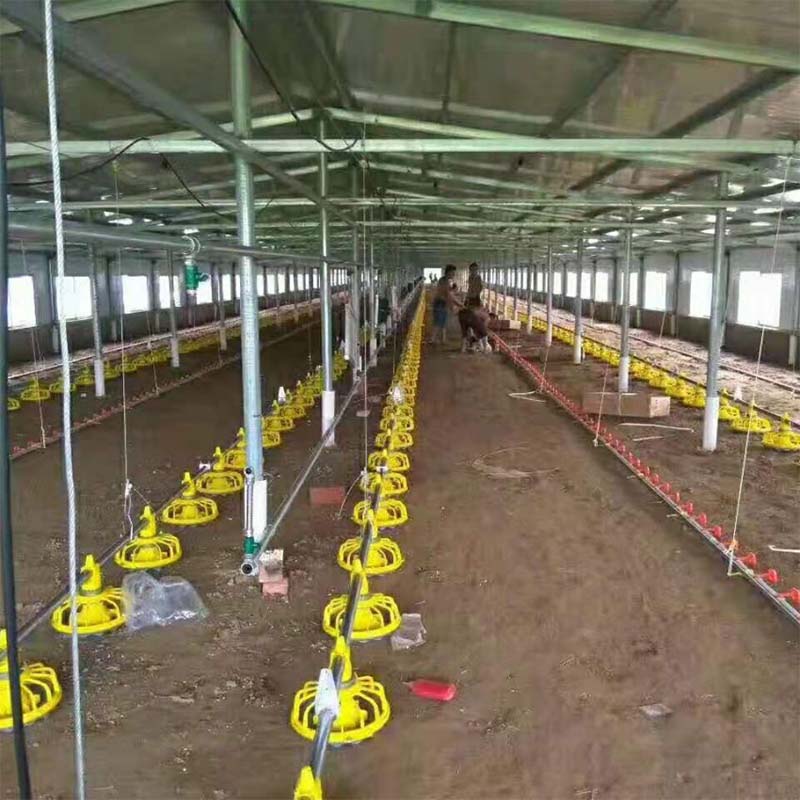

In the rapidly evolving landscape of modern animal husbandry, the efficiency and reliability of farm infrastructure are paramount. Central to optimizing livestock health and productivity is the implementation of a robust automatic drinking line. These sophisticated systems ensure a consistent and clean water supply, which is critical for animal growth, disease prevention, and overall farm profitability. This comprehensive overview delves into the intricate details of automatic drinking line technology, from its manufacturing nuances to its strategic advantages and real-world applications in B2B contexts.

Industry Trends and Market Landscape in Automated Animal Husbandry

The global agricultural sector is undergoing a profound transformation, driven by increasing demand for protein, heightened animal welfare standards, and the imperative for sustainable farming practices. This has spurred significant investment in automation, particularly in integrated systems like the automatic drinking line and the automatic feeding line. Emerging trends indicate a strong shift towards IoT-enabled solutions, real-time monitoring, and data analytics to optimize farm operations. Producers are increasingly seeking systems that offer enhanced biosecurity, reduced labor costs, and improved feed conversion ratios through precise water and nutrient delivery. Moreover, the integration of breeding environment equipment ensures comprehensive control over livestock living conditions, leading to healthier animals and higher yields. The market is projected to expand significantly, with key drivers including technological advancements, rising labor costs, and the need for greater efficiency in large-scale animal production units.

Detailed Manufacturing Process Flow of Automatic Drinking Lines

The production of a high-quality automatic drinking line involves a meticulously engineered process to ensure durability, hygiene, and optimal performance in demanding agricultural environments.

Key Stages of Manufacturing:

- Material Selection & Sourcing: High-grade virgin plastics (e.g., PVC, PP, ABS) for water pipes and nipple housings, ensuring chemical resistance and food-grade safety. Stainless steel (304/316L) for nipple drinker components and critical connection points, offering superior corrosion resistance and longevity. All materials comply with FDA 21 CFR 177.1520 for plastic components and ASTM A276 for stainless steel.

- Precision Extrusion (Pipes): PVC or PP granules are fed into extruders, melted, and forced through dies to form various pipe diameters (e.g., 25mm, 32mm) with consistent wall thickness. This process is monitored for dimensional accuracy and surface finish.

- Injection Molding (Nipple Housings & Connectors): ABS or PP resins are injection-molded under high pressure into precise molds to create the complex geometries of nipple drinker housings, end caps, and various connectors. This ensures tight tolerances and leak-proof assembly.

- CNC Machining (Nipple Drinker Pins): Stainless steel rods are precision-machined using Computer Numerical Control (CNC) lathes to produce the delicate pins and valves of the nipple drinkers. This guarantees accurate water flow control and prevents leakage. Surface passivation treatments are applied for enhanced corrosion resistance.

- Assembly & Integration: Individual components (pipes, nipples, pressure regulators, filters, lifting systems, medication dosers) are assembled. Ultrasonic welding or solvent bonding is used for plastic connections, while threaded or clamped joints are used for other parts, ensuring robust and leak-free systems.

-

Quality Control & Testing: Each manufactured automatic drinking line undergoes rigorous testing.

- Pressure Testing: Systems are subjected to pressures exceeding operational limits (e.g., 3-5 bar) to detect leaks and structural weaknesses.

- Flow Rate Verification: Individual nipple drinkers are tested to ensure consistent water release rates.

- Material Integrity: Non-destructive testing methods ensure the absence of cracks or flaws.

- Compliance: Adherence to international standards such as ISO 9001:2015 for quality management and ANSI/AWWA C900 for PVC pressure pipe.

- Packaging & Shipment: Components are carefully packaged to prevent damage during transit, ready for global distribution.

The typical service life of an automatic drinking line system is designed for 10-15 years, provided proper maintenance and use within specified environmental parameters. Target industries include poultry farming (broilers, layers, breeders), swine production, and other livestock operations requiring precise and hygienic water delivery.

In application scenarios such as large-scale broiler farms, these systems demonstrate significant advantages in energy saving by minimizing water wastage and optimizing water temperature. Their corrosion resistance, particularly due to stainless steel components, ensures longevity even when exposed to medicated water or harsh cleaning agents, dramatically reducing maintenance costs and ensuring consistent operational uptime.

Technical Specifications and System Components

A sophisticated automatic drinking line system is engineered with several key components working in concert to deliver optimal performance. These systems are modular, allowing for tailored configurations based on farm size, animal type, and specific environmental conditions.

Core Components:

- Nipple Drinkers: Precision-engineered stainless steel or plastic nipples designed for specific animal types (e.g., 360° side-action for poultry, top-down for swine), ensuring minimal water waste and preventing spillage.

- Water Supply Pipes: High-quality PVC or galvanized pipes, resistant to UV and chemical corrosion, available in various diameters.

- Pressure Regulators: Crucial for maintaining a consistent water pressure throughout the line, preventing both overflows and insufficient water supply. Typically adjustable from 0.05 MPa to 0.3 MPa.

- Water Filters: Multi-stage filtration systems (sediment, activated carbon) to remove impurities and ensure clean, potable water, enhancing biosecurity.

- Medication Dosers/Proportioners: Integrated units for precise and uniform administration of medication or vitamins through the drinking water, essential for disease prevention and nutritional supplementation.

- Lifting/Suspension System: Winch-operated systems allowing for easy adjustment of drinking line height, accommodating different growth stages of animals and facilitating cleaning.

- End Flushing System: Automated or manual flushing valves at the end of each line to remove sediment and biofilm, maintaining water quality and preventing bacterial growth.

Product Specification Table: Yize Automatic Drinking Line System

| Parameter | Specification |

|---|---|

| Nipple Drinker Material | 304 Stainless Steel + Virgin ABS/PP |

| Pipe Material | High-Grade UV-Stabilized PVC |

| Working Pressure Range | 0.05 MPa - 0.3 MPa (Adjustable) |

| Nipple Capacity (Poultry) | 8-12 birds/nipple (Broilers), 10-15 birds/nipple (Layers) |

| Water Flow Rate (per nipple) | 30-80 ml/min (Adjustable, depending on animal age) |

| Pipe Length Modules | 3m or 4m (customizable) |

| Operational Temperature | 0°C to 50°C |

| System Control | Manual/Automated Water Level/Pressure Control |

Technical Advantages of Advanced Drinking Line Systems

- Enhanced Biosecurity: Closed systems minimize external contamination, reducing the spread of waterborne diseases. This is critical for maintaining flock health and reducing antibiotic usage.

- Optimized Water Consumption: Precision nipple drinkers prevent spillage and waste, leading to significant water savings (up to 30% compared to open trough systems) and better litter quality, reducing ammonia emissions.

- Labor Efficiency: Automation drastically reduces manual labor associated with cleaning and refilling traditional waterers, allowing farm personnel to focus on animal management and other critical tasks.

- Consistent Medication Delivery: Integrated proportioners ensure accurate and uniform distribution of vaccines or supplements, which is vital for preventative health programs.

- Durability and Corrosion Resistance: Utilizes high-grade stainless steel and UV-resistant plastics, ensuring longevity and performance even in aggressive farm environments with frequent cleaning and exposure to chemicals.

- Improved Animal Performance: Consistent access to fresh, clean water at the right pressure encourages optimal hydration, which directly translates to improved feed intake, better weight gain, and higher production rates. Studies have shown that access to clean water can improve broiler weight gain by 5-10%.

- Adaptability: Modular design allows for easy expansion or reconfiguration to adapt to changing farm layouts or animal populations.

Application Scenarios Across Livestock Industries

The versatility of the automatic drinking line system makes it indispensable across various sectors of animal agriculture, optimizing water delivery for different species and production models.

Key Application Areas:

- Poultry Farming: Essential for broiler, layer, and breeder operations. Nipple drinkers are designed to accommodate chicks, growers, and adult birds, ensuring consistent hydration for optimal growth, egg production, and fertility. The ability to raise or lower lines is crucial for managing different flock ages.

- Swine Production: From farrowing crates to finishing pens, these systems provide precise water access for piglets, gilts, sows, and boars. The robust construction withstands aggressive interaction from pigs, while controlled flow prevents excessive water waste common with trough systems.

- Other Livestock: While primarily used in poultry and swine, variations of these systems can be adapted for rabbits, ducks, and other small to medium-sized livestock, where controlled and hygienic water access is beneficial.

In large-scale commercial farms, the integration of these drinking lines with automatic feeding line systems and advanced breeding environment equipment creates a highly efficient, controlled, and labor-saving environment. This holistic approach significantly boosts farm productivity and ensures animal welfare, meeting the stringent demands of modern food production.

Vendor Comparison: Yize Machine vs. Competitor A in Automatic Drinking Line Systems

Selecting the right supplier for an automatic drinking line system is a critical decision for any agricultural enterprise. A direct comparison of key features, performance metrics, and support structures can highlight differentiating factors. Yize Machine positions itself as a leader in delivering robust, high-performance solutions designed for longevity and efficiency.

Automatic Drinking Line System Comparison

| Feature | Yize Machine System | Competitor A System |

|---|---|---|

| Nipple Drinker Design | 304 Stainless Steel (dual seal), 360° side-action with high flow sensitivity | 201 Stainless Steel (single seal), top-down action with moderate sensitivity |

| Water Pipe Material | Premium Virgin PVC (UV & Chemical Resistant) | Standard PVC (less UV stability) |

| Pressure Regulator | High-precision diaphragm type, external flush, adjustable from 0.05-0.3 MPa | Spring-loaded, internal flush, adjustable 0.1-0.2 MPa |

| Medication Doser Integration | Seamless integration, various dosing ratios (e.g., 1:100 to 1:500) | Optional add-on, limited ratio selection |

| Biosecurity Features | Fully closed system, end flushing, integrated filtration, anti-algae opaque pipes | Partially closed, basic filtration, translucent pipes |

| Service Life Expectancy | 10-15 years (with proper maintenance) | 5-8 years |

| Warranty | 2-year full system warranty, 5-year on specific components | 1-year limited warranty |

This comparison highlights Yize Machine's commitment to superior material quality, advanced design, and comprehensive support, translating into a lower total cost of ownership and enhanced operational reliability for our clients.

Customized Solutions for Diverse Agricultural Needs

Recognizing that every farm operation has unique requirements, Yize Machine specializes in providing highly customized automatic drinking line solutions. Our engineering team collaborates closely with clients to design systems that perfectly align with their specific needs, whether it's for a small-scale integrated farm or a multi-shed commercial complex.

Customization Options Include:

- System Layout and Length: Tailored pipe lengths, spacing, and number of lines per shed to optimize coverage and animal density.

- Nipple Drinker Type and Spacing: Selection of specific nipple designs (e.g., high flow, low flow, 360°, side-action) and customized spacing to suit different animal ages, sizes, and species.

- Water Treatment & Filtration: Integration of advanced filtration, UV sterilization, or water softening units based on local water quality analysis.

- Medication Dosing Systems: Choice of high-precision dosers with variable injection rates and multi-line integration capabilities.

- Automation & Monitoring: Integration with central farm management systems, including automated flushing, pressure sensors, flow meters, and remote monitoring capabilities for real-time data access.

- Environmental Adaptation: Specialized components for extreme climates (e.g., anti-freeze systems for cold regions, heat-resistant materials for hot climates).

Our approach ensures that clients receive a solution that not only meets their current operational demands but is also scalable and adaptable for future growth, maximizing their return on investment.

Application Case Studies and Customer Experience

Yize Machine has a proven track record of successful deployments across various scales and geographies, demonstrating the tangible benefits of our automatic drinking line systems.

Case Study 1: Large-Scale Broiler Farm (Southeast Asia)

Client: "AgroGenetics Inc.," operating 12 broiler sheds, each housing 50,000 birds.

Challenge: Inconsistent water supply, high water wastage, and significant labor costs for maintaining traditional bell drinkers, leading to wet litter issues and increased disease incidence.

Solution: Yize Machine designed and installed a fully automated drinking line system with our premium stainless steel nipple drinkers, integrated pressure regulators, and an automated end-flushing system across all 12 sheds.

Results:

- Water consumption reduced by 28%, saving approximately $15,000 annually on water bills.

- Labor hours for water system maintenance decreased by 75%.

- Incidence of respiratory issues and footpad dermatitis reduced by 40% due to drier litter conditions.

- Improved Feed Conversion Ratio (FCR) by 3 points, leading to an estimated $50,000 increase in annual revenue.

Customer Feedback: "The Yize Machine drinking line has been a game-changer for our operation. The birds are healthier, the sheds are cleaner, and our operational costs have significantly dropped. The system's reliability is truly impressive." - Mr. Tan, Farm Manager.

Case Study 2: Swine Breeding Facility (European Union)

Client: "PorkWorks GmbH," a leading genetic breeding center for swine.

Challenge: Ensuring precise medication delivery for piglets and sows, while minimizing bacterial biofilm buildup in water lines, critical for biosecurity in a breeding environment.

Solution: Yize Machine provided a customized system featuring advanced nipple drinkers designed for swine, coupled with an integrated high-precision medication doser and a robust filtration system. Opaque pipes were used to prevent algae growth.

Results:

- Achieved 99.5% accuracy in medication delivery across all pens.

- Biofilm growth reduced by 85%, significantly improving water quality test results.

- Reduced piglet mortality rates by 1.5% during critical weaning stages.

Customer Feedback: "The biosecurity features of the Yize drinking system are exactly what our breeding facility needed. Consistent water quality and precise dosing have made a measurable difference in our herd health and productivity." - Dr. Schmidt, Head Veterinarian.

Certifications, Authoritative References, and Trustworthiness

Yize Machine adheres to the highest global standards in the manufacturing and deployment of our automatic drinking line systems, ensuring unparalleled quality, safety, and reliability. Our commitment to excellence is underpinned by robust certifications and transparent operational practices.

Authoritative Standards and Certifications:

- ISO 9001:2015 Certified: Our manufacturing processes and quality management systems are certified to ISO 9001:2015, guaranteeing consistent product quality and continuous improvement.

- CE Mark Compliance: All relevant components bear the CE mark, indicating compliance with European health, safety, and environmental protection standards.

- FDA Compliant Materials: Plastic components in contact with drinking water adhere to FDA 21 CFR 177.1520 regulations for safe food contact materials.

- SGS Testing: Independent third-party testing by SGS confirms the durability and material composition of our stainless steel and plastic components.

Lead Time and Fulfillment Details:

We understand the time-sensitive nature of agricultural projects. Our streamlined production and logistics ensure efficient order fulfillment.

- Standard Orders: Typically shipped within 15-25 business days, depending on system complexity and quantity.

- Customized Solutions: Project-specific timelines are provided after detailed design consultation, usually ranging from 30-45 business days.

- Logistics: We partner with reputable global freight forwarders to ensure timely and secure delivery to your specified location, with comprehensive tracking provided.

Warranty Commitments and Customer Support:

Yize Machine stands behind the quality of its products with comprehensive warranty and dedicated after-sales support.

- 2-Year Full System Warranty: Covers manufacturing defects and material failures under normal operating conditions.

- 5-Year Component Warranty: Extended warranty on key components such as stainless steel nipple parts and pressure regulator diaphragms.

- Lifetime Technical Support: Our team of experienced engineers provides ongoing technical assistance, troubleshooting, and maintenance guidance via phone, email, and remote support tools.

- Spare Parts Availability: A comprehensive inventory of genuine spare parts is maintained for rapid dispatch, minimizing downtime.

- Installation & Training: Optional on-site installation supervision and operational training can be provided to ensure seamless integration and optimal system utilization.

Frequently Asked Questions (FAQ) about Automatic Drinking Line Systems

Q1: How does an automatic drinking line system improve animal health?

A1: These systems provide continuous access to fresh, clean water, reducing the risk of waterborne diseases. The closed design prevents contamination from feed or litter, and consistent water pressure ensures adequate hydration, which is crucial for animal metabolism, growth, and immune function. Integrated medication dosers also allow for precise preventative treatment.

Q2: What is the typical lifespan of an automatic drinking line?

A2: With proper installation and routine maintenance, a high-quality system from Yize Machine is designed to last 10 to 15 years. Components like stainless steel nipples are particularly durable, and easily replaceable parts ensure long-term functionality.

Q3: Can these systems be integrated with existing farm infrastructure?

A3: Yes, our systems are modular and highly adaptable. They can be seamlessly integrated with existing water supply lines, automatic feeding line systems, and breeding environment equipment. Our technical team provides design and installation guidance to ensure smooth integration.

Q4: How often should the drinking lines be cleaned?

A4: Regular flushing is recommended, typically daily or every few days, especially if medication or supplements are administered. A complete system disinfection should be performed between flocks or cycles to eliminate biofilm and pathogens. Our systems include automated end flushing for convenience.

Q5: What are the main differences between poultry and swine drinking line nipples?

A5: Poultry nipples are typically designed for 360° side-action with low activation force to suit the pecking motion of birds. Swine nipples are more robust, often top-down activated, and designed to withstand the biting and nudging of pigs, with higher flow rates suitable for their larger water intake needs.

Conclusion: Elevating Livestock Productivity with Yize Machine

The implementation of an advanced automatic drinking line from Yize Machine represents a strategic investment in the future of modern animal husbandry. By ensuring a consistent supply of clean, fresh water, these systems are pivotal in enhancing animal health, improving productivity, and driving operational efficiencies. Our commitment to quality, backed by stringent manufacturing processes, robust certifications, and dedicated customer support, positions Yize Machine as a trusted partner for B2B clients seeking to optimize their farm operations. Embrace the future of farming with intelligent hydration solutions that deliver measurable benefits and sustainable growth.

References

- National Agricultural Library. (2023). Animal Watering Systems. U.S. Department of Agriculture.

- Food and Drug Administration. (2023). Code of Federal Regulations Title 21 - Food and Drugs, Part 177 - Indirect Food Additives: Polymers.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- American Society of Agricultural and Biological Engineers. (2022). Standards for Livestock Watering Systems.

- Poultry Science Association. (2021). Impact of Water Quality and Delivery Systems on Broiler Performance and Health.

This is the last article

-

Automatic Drinking Line: Efficient, Hygienic Livestock Hydration

NewsAug.23,2025

-

High-Performance Feed Hammer Mill for Efficient Feed Grinding

NewsAug.22,2025

-

Best Feed Miller with Mixer | Vertical Animal Feed Solutions

NewsAug.21,2025

-

Premium Poultry Breeding Cages | Modern Layer Systems for Sale

NewsAug.19,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.18,2025

-

Custom Cast Iron Enamel Milk Pan Stew Pot-Anping Yize|Heat Retention,Custom Logo

NewsAug.18,2025