Poultry Cages Manufacturers: Need Automatic, Durable Cages?

Oct . 07, 2025 08:55 Back to list

Poultry Cages Manufacturers: Need Automatic, Durable Cages?

Inside the fast-evolving world of poultry cages manufacturers

If you’ve been shopping around for poultry cages manufacturers, you’ve probably noticed the landscape shifting—toward heavier coatings, smarter automation, and frankly, more pragmatic ROI models. I’ve walked a few factory floors in Hebei and Shandong; the difference between a good cage line and a great one often comes down to steel chemistry, weld discipline, and whether they test like they mean it.

What’s trending (and why it matters)

Actually, three trends keep popping up: Zn-Al-Mg coatings for longer life, fully integrated manure belts for labor savings, and modular H-type stacks that squeeze more birds per square meter without compromising airflow. Many customers say automated feeding plus belt removal cuts daily labor by ≈30–45%—not magic, just mechanics.

Product spotlight: H type 3 or 4 tiers broiler chicken cage

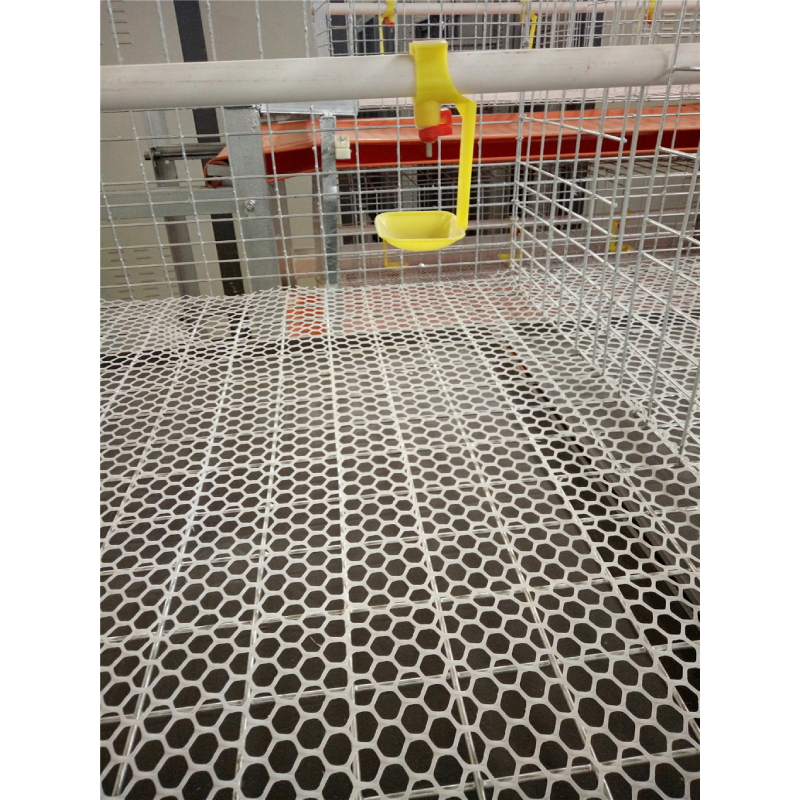

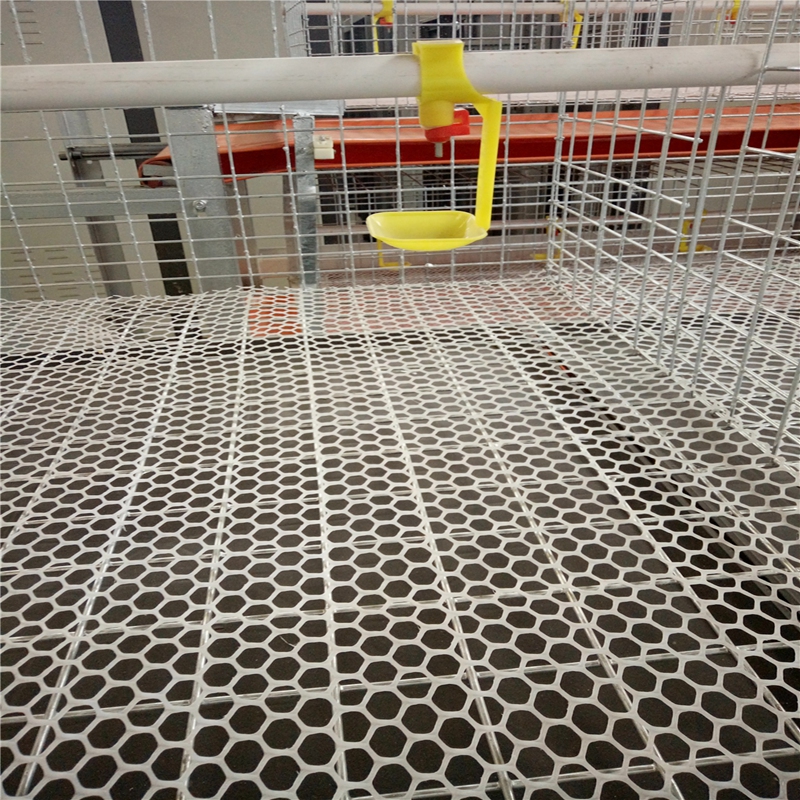

Built in Jinwang Western Street, Industrial Zone, Anping County, Hengshui, Hebei, the H-type stack is all about corrosion resistance, high strength, and practical disease prevention. To be honest, it’s the kind of kit that quietly boosts land-use efficiency when you’re chasing throughput.

| Parameter | Typical spec (≈ / ranges; real-world use may vary) |

|---|---|

| Tiers | 3 or 4 |

| Module size (L×W) | ≈1200–1400 × 600–700 mm per cage |

| Wire & frame material | Q235 low-carbon steel, precision welded |

| Surface treatment | Hot-dip galvanizing ≥275 g/m² or Zn-Al-Mg; electro-galv for indoor |

| Wire diameter | ≈2.3–3.8 mm |

| Mesh aperture | Floor ≈20×50 mm; side ≈50–60×50 mm |

| Capacity | ≈30–45 broilers/cage depending on weight & ventilation |

| Systems | Auto feeding, nipple drinking (SS304), manure belt, optional PLC |

| Service life | ≈10–20 years (coating, cleaning, ammonia levels) |

| Compliance refs | ISO 1461, ASTM A641/A641M, ASTM B117 (testing) |

From steel coil to stacked rows: process and testing

Materials: certified Q235 coil, wire-drawn and pickled. Methods: resistance welding with current control, post-weld passivation, and hot-dip or Zn-Al-Mg coating. Testing: zinc thickness by magnetic gauge, weld shear/tensile samples each shift, and 240–720 h salt-spray (ASTM B117) on witness panels. In fact, better lines also run belt load tests and continuous motor heat-rise checks. Typical users? Contract growers, integrators, and expansion farms trying to standardize batches.

Advantages we’ve seen on real farms

Better hygiene (targeted droppings removal), steadier feed conversion, and a surprise benefit: easier auditing for welfare protocols. One buyer told me the belt system alone reduced ammonia spikes during wet seasons. And yes, the land-use efficiency is a quiet profit lever.

How poultry cages manufacturers stack up: quick vendor snapshot

| Vendor | Coating quality | Lead time | Customization | Certs | After-sales |

|---|---|---|---|---|---|

| Yize Machine (Anping, Hebei) | Hot-dip / Zn-Al-Mg, batch-tested | ≈25–40 days | Tier count, mesh, belt width | ISO 9001; CE where required | Install guides, spares, remote |

| Local Fabricator | Electro-galv (thin) | Fast | Basic | Varies | Limited |

| Import Brand A | Zn-Al-Mg premium | Longer | High | ISO/CE extensive | Global service |

Customization, compliance, and the fine print

Good poultry cages manufacturers will tweak mesh apertures for bird weight, widen belts for wetter litter, and match motors to local voltage. Ask for coating certificates, zinc-thickness logs, and salt-spray reports. Also check alignment with OIE welfare guidance and local veterinary directives; it’s not just paperwork—it keeps auditors calm.

Two quick case notes

- Kenya, 20k birds: 4-tier H-type retrofit; labor down ≈40%, mortality trimmed by 0.6% over two cycles.

- Poland, mid-size integrator: Zn-Al-Mg upgrade; belt scraper redesign cut downtime, and service life forecast +4–5 years.

Last thought: compare total cost of ownership, not just invoice price. Coating mass, weld quality, drive reliability—these are the quiet cost killers (or savers).

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles

- ASTM A641/A641M: Zinc-Coated (Galvanized) Carbon Steel Wire

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus

- WOAH/OIE Terrestrial Animal Health Code (Poultry welfare guidance)

- FAO: Poultry production and technology resources

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025

-

What is a Silo Automatico? Industry Applications, Benefits & Future Trends

NewsNov.20,2025

-

Practical Guide to Egg Laying Chicken Cages for Sale – Durable, Scalable & Sustainable

NewsNov.19,2025