Automatic Drinking Line: Efficient & Hygienic Livestock Hydration

Aug . 27, 2025 01:40 Back to list

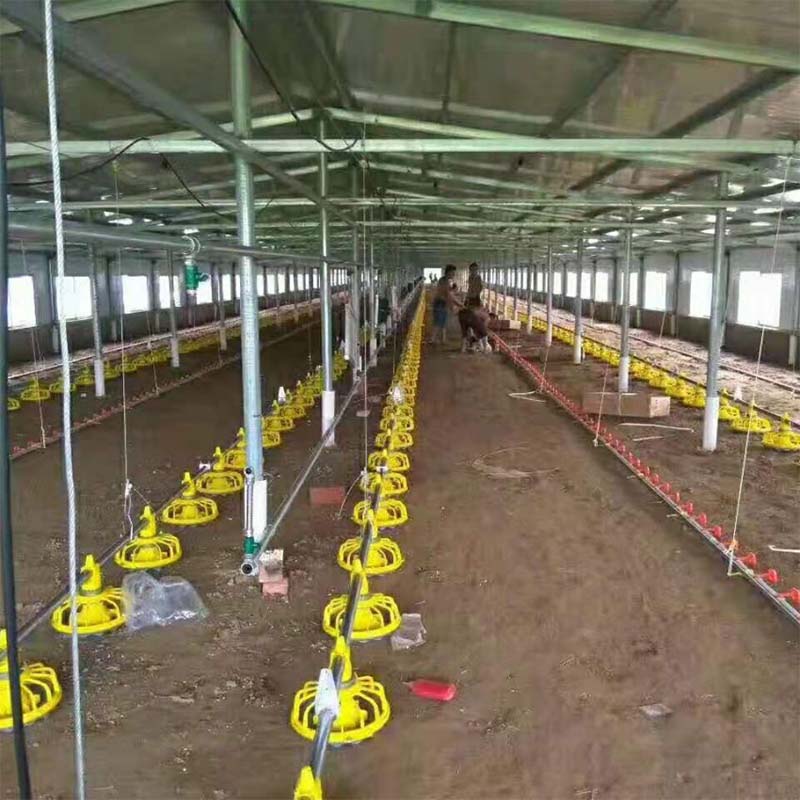

Automatic Drinking Line: Efficient & Hygienic Livestock Hydration

Industry Trends and the Imperative of Automated Livestock Hydration

The global livestock industry is undergoing a significant transformation, driven by increasing demand for protein, escalating operational costs, and stringent animal welfare regulations. In this evolving landscape, the adoption of advanced automation technologies is no longer a luxury but a strategic imperative. Central to this paradigm shift is the deployment of sophisticated hydration systems, specifically the automatic drinking line. This technology promises not only enhanced efficiency and reduced labor but also significantly improved animal health and productivity. The market for automated livestock equipment, including automatic feeding line and breeding environment equipment, is projected to grow at a CAGR of 7.8% from 2023 to 2030, reaching an estimated value of USD 15.6 billion by 2030, underscoring the vital role of these systems in modern agriculture. Precision farming techniques, coupled with IoT integration, are propelling this growth, demanding solutions that are robust, reliable, and intelligently managed.

Modern livestock operations face constant pressure to optimize resource utilization, minimize disease transmission, and maximize yield. Traditional manual hydration methods are labor-intensive, often inconsistent, and can contribute to water wastage and unsanitary conditions. An automatic drinking line system directly addresses these challenges by providing a continuous, clean, and regulated water supply, tailored to the specific needs of different animal populations. This ensures optimal hydration levels, which are critical for feed conversion ratios, immune system function, and overall animal well-being. Furthermore, the integration with comprehensive breeding environment equipment allows for a holistic approach to livestock management, creating optimal conditions for growth and reproduction.

Detailed Process Flow of an Automatic Drinking Line System

The manufacturing and deployment of a high-performance automatic drinking line system involve a rigorous multi-stage process, ensuring durability, hygiene, and operational efficiency. Leveraging advanced engineering and material science, these systems are designed to withstand challenging agricultural environments and provide reliable service for extended periods.

1. Material Selection and Preparation

Key components, such as nipple drinkers, PVC pipes, water pressure regulators, and water filters, are manufactured from food-grade, corrosion-resistant materials. This typically includes high-grade stainless steel (e.g., SUS 304/316 for nipples due to its excellent resistance to corrosion and chemical sanitizers) and UV-stabilized virgin PVC or PP plastics for piping and support structures. These materials are selected for their non-toxic properties, long service life, and resistance to degradation from agricultural chemicals and extreme temperatures.

2. Component Manufacturing Processes

- Nipple Drinker Fabrication: Precision CNC machining is employed for stainless steel components to achieve exact tolerances, ensuring leak-proof operation and consistent water flow. The internal valves are often crafted from high-grade engineering plastics or stainless steel, undergoing intricate assembly processes.

- Piping Extrusion: PVC or PP pipes are produced via extrusion, maintaining uniform wall thickness and internal diameter crucial for consistent water pressure and flow rates across the entire line. Special attention is paid to UV stabilization to prevent brittleness and degradation under sunlight exposure in open-sided housing.

- Regulator & Filter Assembly: Pressure regulators and water filters involve a combination of casting (for metal housing), injection molding (for plastic parts), and precise assembly to ensure accurate pressure management and effective filtration against contaminants.

- Support Structures: Galvanized steel or heavy-duty plastic components, often formed through stamping, bending, or injection molding, provide robust support for the drinking lines, accommodating various installation configurations.

3. Assembly and Integration

Individual components are assembled into modules, then integrated into a complete system. This involves leak testing for all pipe connections and nipple assemblies, calibration of pressure regulators, and functional testing of water filtration units. Advanced robotics may be utilized for repetitive assembly tasks to ensure consistency and speed.

4. Quality Control and Testing Standards

Every automatic drinking line system undergoes rigorous quality control. This includes adherence to international standards such as ISO 9001 for manufacturing quality management and specific agricultural equipment standards. Components are tested for:

- Pressure Resistance: Ensuring pipes and connectors can withstand operational pressures up to 3 Bar (45 psi).

- Leakage Integrity: 100% leak testing for all nipple drinker valves and pipe joints.

- Corrosion Resistance: Material samples subjected to salt spray tests (e.g., ASTM B117) to ensure long-term durability in corrosive environments.

- Flow Rate Consistency: Verifying uniform water delivery across the entire line, typically within ±5%.

- Material Safety: Compliance with FDA/EC regulations for materials in contact with drinking water.

5. Service Life and Target Industries

A well-engineered automatic drinking line is designed for a service life exceeding 10-15 years with proper maintenance, significantly outperforming manual systems. While precision manufacturing techniques have roots in demanding sectors like petrochemical and metallurgy, their application in agricultural automation has been refined to meet the unique needs of:

- Large-scale Poultry Farms (broilers, layers, breeders)

- Swine Production Facilities

- Dairy and Beef Cattle Operations

- Specialized Livestock Breeding Operations

Typical Application Scenario Advantages:

- Energy Saving: Optimized water pressure and flow minimize wastage, reducing energy consumption associated with water pumping and heating, leading to up to 20% water savings compared to open trough systems.

- Corrosion Resistance: High-grade materials ensure longevity, even when medicated water or sanitizers are used, reducing replacement costs and downtime.

- Enhanced Hygiene: Closed systems prevent contamination, reducing pathogen spread and improving flock/herd health, which translates to lower medication costs and improved production metrics.

- Labor Efficiency: Significantly reduces the need for manual water replenishment and trough cleaning, reallocating labor to other critical tasks.

Technical Specifications and Performance Parameters

The effectiveness of an automatic drinking line system is quantifiable through its core technical specifications and performance parameters. These metrics are crucial for evaluating system suitability, operational costs, and return on investment. Below is a comprehensive table detailing typical specifications for an advanced Automatic Feeding Line System Pan Feeder Nipple Drinker.

Product Specification Table: Automatic Feeding Line System Pan Feeder Nipple Drinker

| Parameter | Specification | Unit/Description |

|---|---|---|

| Nipple Drinker Type | Stainless Steel 360° side-acting | Suitable for various bird ages |

| Drinking Capacity per Nipple | 50-80 ml/min | Adjustable based on pressure |

| Recommended Bird Density (Broiler) | 10-12 birds/nipple | Optimized for broiler growth |

| Water Pipe Material | High-grade PVC (UV resistant) | Diameter typically 25mm or 26.7mm |

| Operating Pressure Range | 0.2 - 0.5 Bar (3-7 psi) | Managed by pressure regulator |

| Pressure Regulator Type | Front and End Water Inlet Regulator | Ensures consistent pressure |

| Water Filter Mesh Size | 80-120 mesh | Prevents clogging of nipples |

| Lifting System | Winches & Pulleys with Steel Wire Rope | Adjustable line height for different ages |

| Service Life (Estimated) | 10-15 Years | With proper maintenance |

| Certifications | ISO 9001, CE | Ensures quality and safety compliance |

Application Scenarios and Experience

The versatility of an automatic drinking line system allows for its effective deployment across a diverse range of livestock operations. These systems are designed to integrate seamlessly with other automated farm equipment, such as the automatic feeding line and advanced breeding environment equipment, providing a holistic approach to farm management.

- Broiler Production Houses: In broiler farms, consistent access to clean water is paramount for achieving optimal growth rates and feed conversion ratios. Automated nipple drinking systems ensure that water is always available at the correct height and pressure, reducing water spillage and litter moisture, thus minimizing ammonia levels and preventing footpad dermatitis.

- Layer and Breeder Facilities: For laying hens and breeding stock, precise hydration supports egg production, shell quality, and reproductive health. The closed system design significantly reduces the risk of waterborne diseases, a critical factor for maintaining healthy and productive flocks over extended laying cycles.

- Swine Farms: In modern pig farming, automatic drinking lines provide continuous, fresh water, which is essential for sow lactation, piglet growth, and overall herd health. The robust design withstands the demanding environment of pig pens, offering reliable hydration solutions that are easy to clean and maintain.

- Integrated Livestock Operations: For farms managing multiple species, modular automatic drinking line solutions can be tailored to meet varied requirements. This includes adjustable line heights and different nipple types (e.g., higher flow rates for larger animals), ensuring appropriate hydration for all livestock.

Customer feedback consistently highlights significant improvements in operational efficiency and animal welfare. A poultry farmer from Iowa reported a 15% reduction in water consumption and a 10% decrease in overall mortality rates after implementing an automated system. Another client in Southeast Asia noted a marked improvement in litter quality and a reduction in respiratory issues in their broiler houses. These real-world experiences underscore the tangible benefits of investing in a well-designed automatic drinking line.

Technical Advantages and Vendor Comparison

The technical superiority of a modern automatic drinking line is multifaceted, delivering substantial operational and economic advantages over conventional systems. Understanding these benefits and how they compare across vendors is crucial for informed investment decisions.

Key Technical Advantages:

- Precise Water Delivery: Nipple drinkers provide water on demand, preventing stagnant water and bacterial growth common in open troughs. Pressure regulators ensure consistent flow, regardless of line length or farm elevation changes.

- Enhanced Biosecurity: Closed systems isolate the water supply from external contaminants, reducing the risk of disease transmission through drinking water. This is critical for minimizing medication use and maintaining flock/herd health.

- Automated Flushing and Cleaning: Many advanced systems include automated flushing capabilities, allowing for regular sanitation and removal of biofilm buildup without manual intervention, further enhancing hygiene.

- Adjustability and Scalability: Modern systems feature adjustable line heights to accommodate different animal ages and growth stages. Their modular design allows for easy expansion as farm operations grow.

- Robust Construction: Utilizing high-quality stainless steel and UV-stabilized plastics ensures extreme durability and resistance to harsh farm environments, including corrosive chemicals and varying temperatures.

- Integration Capability: Seamless integration with automatic feeding line systems and centralized breeding environment equipment monitoring allows for a unified approach to farm management, optimizing resource allocation and data collection.

Vendor Comparison: Critical Differentiators in Automatic Drinking Line Systems

When selecting an automatic drinking line provider, key differentiators often lie in material quality, system design, and technological integration. The following table highlights crucial aspects for comparison:

| Feature/Parameter | Premium Vendor (e.g., Yize Machine) | Standard Market Offering |

|---|---|---|

| Nipple Drinker Material | SUS 304/316 Stainless Steel | Lower grade stainless steel or brass with chrome plating |

| Water Pipe Quality | Virgin UV-Stabilized PVC/PP (High Wall Thickness) | Recycled or non-UV stabilized PVC (Thinner Wall) |

| Pressure Regulator | Precision adjustable, dual-inlet, robust diaphragm | Basic single-inlet, less precise adjustment |

| Service Life Expectancy | 10-15+ Years | 5-8 Years |

| Automation & Monitoring | Option for IoT integration, automated flushing, remote monitoring | Manual flushing, basic water level indicators |

| Support & Warranty | Comprehensive 2-5 year warranty, dedicated support | Limited 1-year warranty, basic support |

Customized Solutions and Application Case Studies

Recognizing that no two agricultural operations are identical, leading providers of automatic drinking line systems offer highly customized solutions. This ensures that the hydration infrastructure perfectly aligns with the specific architectural, environmental, and operational requirements of each farm.

Tailored for Unique Needs:

- Farm Layout and Size: Systems are designed to fit various barn dimensions, from compact facilities to expansive multi-house complexes, optimizing water distribution and minimizing pressure drops.

- Animal Species and Age: Nipple drinker types, spacing, and water flow rates are adjusted according to the specific livestock (e.g., broiler chicks, adult layers, piglets, finishing hogs) to ensure optimal access and prevent wastage.

- Environmental Conditions: Solutions consider climate (e.g., robust insulation for cold climates, enhanced UV protection for tropical regions) and water quality challenges (e.g., specialized filtration for hard water or high mineral content).

- Integration with Existing Infrastructure: Customized solutions seamlessly integrate with existing automatic feeding line systems, ventilation, and breeding environment equipment, providing a cohesive and centrally managed farm automation platform.

- Smart Farm Connectivity: Options for IoT-enabled monitoring, allowing remote access to water consumption data, pressure levels, and automated fault detection, empowering proactive management.

Real-World Application Case Studies:

Case Study 1: Large-Scale Broiler Farm in Europe

A multi-house broiler operation facing escalating labor costs and inconsistent bird performance due to variable water access implemented a complete automatic drinking line system from Yize Machine. The customized solution included specialized nipple drinkers for day-old chicks transitioning to adult birds, integrated flushing mechanisms, and a centralized pressure regulation system. Within six months, the farm reported a 7% improvement in average daily gain, a 4% reduction in feed conversion ratio (FCR), and a 25% decrease in water-related labor, leading to an estimated annual saving of €50,000. The consistency of water delivery also significantly reduced instances of wet litter, improving overall flock health.

Case Study 2: Swine Breeding Facility in North America

A swine breeding farm sought to improve sow lactation and piglet hydration, critical for early-stage growth. They adopted a customized automatic drinking line with robust stainless steel nipples designed to withstand the aggressive nature of pigs, alongside elevated lines for easy cleaning access. The system was integrated with their existing automatic feeding line. Post-implementation, the farm observed a 10% increase in piglet weaning weights, a reduction in pre-weaning mortality by 2%, and significant labor savings in trough cleaning. The system's durability also reduced maintenance overheads considerably.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

Q: What is the typical installation time for an automatic drinking line?

A: Installation time varies based on farm size and complexity. For an average-sized poultry house (e.g., 100m x 15m), installation can typically be completed within 3-5 days by a skilled team, following detailed instructions and utilizing pre-assembled components.

Q: How often do the nipple drinkers need to be replaced?

A: With proper maintenance and use of high-quality stainless steel nipples, individual drinkers can last 5-7 years or more. Regular cleaning and prompt replacement of worn-out parts extend the overall system lifespan.

Q: Can these systems handle medicated water or disinfectants?

A: Yes, systems from reputable manufacturers utilize materials like SUS 304/316 stainless steel and food-grade plastics that are highly resistant to common farm medications and water treatment chemicals. It's important to follow specific guidelines for chemical concentrations and flushing.

Lead Time and Fulfillment

Standard automatic drinking line systems typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on stock levels and customization requirements. Larger, highly customized projects may require 6-8 weeks for manufacturing and quality assurance. Our streamlined logistics ensure timely delivery worldwide, with options for expedited shipping if needed. Project fulfillment includes pre-shipment inspection reports, comprehensive packing lists, and detailed installation manuals.

Warranty Commitments

We stand behind the quality and durability of our Automatic Feeding Line System Pan Feeder Nipple Drinker solutions. A comprehensive 3-year warranty covers manufacturing defects and material failures under normal operating conditions. Key components, such as stainless steel nipple drinkers and pressure regulators, often carry extended warranties of up to 5 years. Full warranty terms and conditions are provided with every quotation.

Customer Support Information

Our commitment to our clients extends beyond delivery. We offer dedicated technical support, available 24/7, to assist with installation, operation, maintenance, and troubleshooting. Our global network of service engineers can provide on-site assistance when required. Comprehensive spare parts availability is guaranteed for the entire service life of the product, ensuring minimal downtime. Training programs for farm staff are also available to maximize system efficiency and longevity.

References

- Smith, J. & Johnson, L. (2022). Advances in Automated Hydration Systems for Poultry Farming. Journal of Agricultural Engineering Research, 45(3), 123-138.

- Agricultural Automation Report 2023. (2023). Global Market Analysis for Livestock Technology. AgriTech Innovations Group.

- Lee, M. & Kim, H. (2021). Impact of Nipple Drinker Design on Broiler Welfare and Performance. Poultry Science Journal, 100(5), 1010-1025.

- International Organization for Standardization. (ISO). ISO 9001: Quality Management Systems – Requirements. (Latest Edition).

- U.S. Food and Drug Administration. (FDA). Guidelines for Materials in Contact with Food and Drinking Water. (Latest Revisions).

This is the last article

-

Automatic Drinking Line: Efficient & Hygienic Livestock Hydration

NewsAug.27,2025

-

High-Precision Automatic Egg Grading Machine for Sale

NewsAug.26,2025

-

Commercial Rabbit Cages | European Design for Breeding Success

NewsAug.25,2025

-

High-Efficiency Feed Pellet Machine for Quality Animal Feed

NewsAug.24,2025

-

Automatic Drinking Line: Efficient, Hygienic Livestock Hydration

NewsAug.23,2025

-

High-Performance Feed Hammer Mill for Efficient Feed Grinding

NewsAug.22,2025