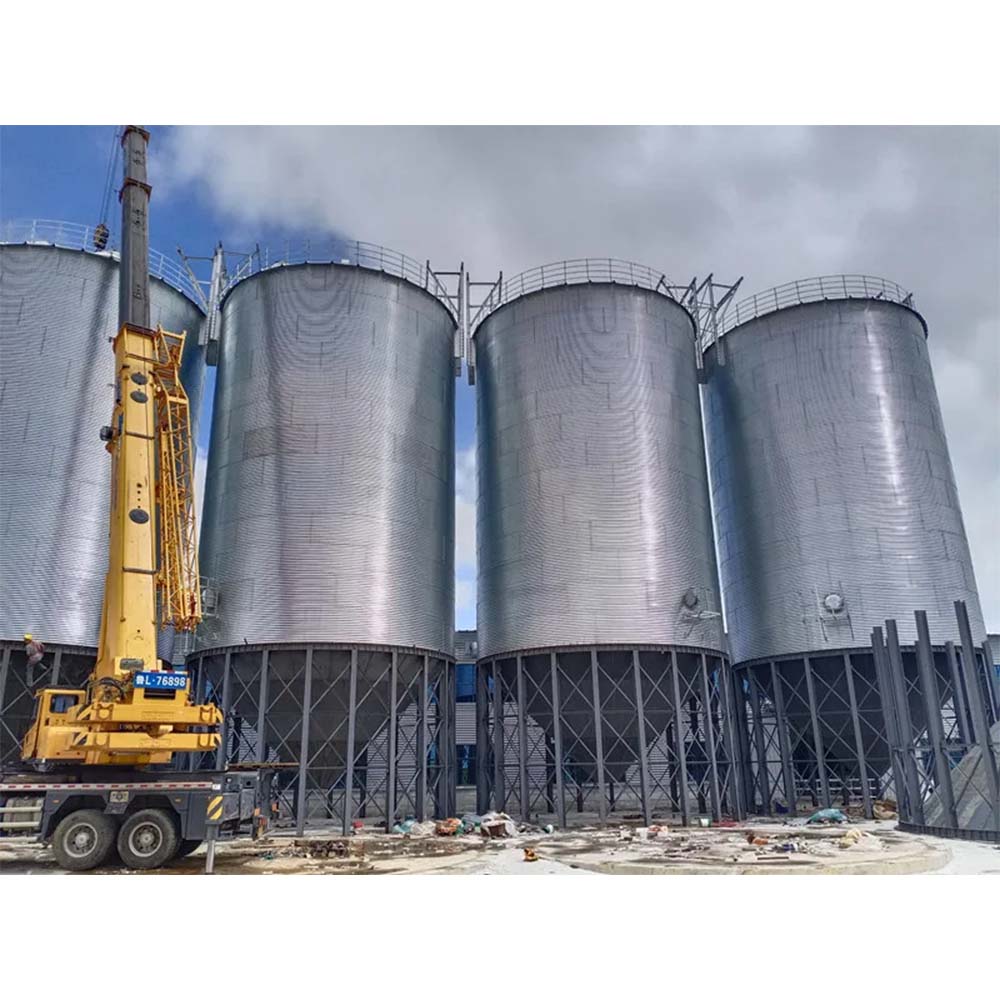

30 50 100 200 500 1000 1500 matani makabati msonkhano chakudya mbewu phala tirigu yosungirako zitsulo silo

- * Msonkhano, wosavuta kutumiza ndikusunga katundu.

- * Silo yachitsulo yoyimirira imatha kupulumutsa malo.

- *Mbale zamalata wotentha-kuviika (275g/m2-600g/m2), ZOSAVUTA MADZI NDI KUTI-DZIDZIWI.

- *Hopper pansi ili ndi mtengo wotsika mtengo.

- *Silos amatha kusunga tirigu mosamala ndikupulumutsa mtengo wantchito ndi malo.

- Mwasayansi, mphamvu ya silo iyenera kuyezedwa ndi voliyumu (m3).

- Ngakhale mu silo yemweyo, matani osungira adzakhala osiyana ndi mbewu zosiyanasiyana zokhala ndi makulidwe osiyanasiyana.

- Gome lotsatirali limawerengeredwa kutengera kuchuluka kwambewu kwa 0.75kg/m3, ndipo ndithudi TSE imasintha makina a silo kukhala apadera kwa inu.

|

Chitsanzo |

Voliyumu |

Kutalika kwa Eve(m) |

Kutalika Konse(M) |

Kulemera (Ton) |

|

Mtengo wa TCZK05509 |

272 |

13.73 |

15.16 |

9 |

|

Chithunzi cha TCZK06410 |

411 |

15.3 |

16.95 |

12 |

|

Mtengo wa TCZK07310 |

550 |

14.64 |

16.5 |

14.5 |

|

Mtengo wa TCZK08210 |

708 |

16.22 |

18.29 |

16.18 |

|

Mtengo wa TCZK09011 |

960 |

17.79 |

20.07 |

25.5 |

|

Chithunzi cha TCZK10013 |

1360 |

20.47 |

22.97 |

30.766 |

|

Chithunzi cha TCZK11012 |

1536 |

19.79 |

22.5 |

35.5 |

what is silo?

Mankhokwe achitsulo (omwe amatchedwanso nkhokwe zosungiramo tirigu, nkhokwe za tirigu) ndi nkhokwe zachitsulo zokhala ndi nkhokwe pansi. Assembly galvanized grain steel silos amamangidwira pamapangidwe othandizira kuti zinthu zofewa zitsitse mosavuta kudzera mu mphamvu yokoka. Masilo ambewu amakhala ndi kusintha kosalala kwa khoma popanda masitepe kapena ma flanges kuti apereke zotulutsa zoyera kwambiri kuchokera ku silo. Zinthu zosungidwa mkati mwa silo zimakhala zolekanitsidwa ndi nthaka, motero zimalepheretsa chinyezi ndikulola kulumikizidwa kwa ma silo kudzera pa matepi, kumathandizira kutulutsa bwino kapena mlingo.

The hopper, rings and support steel are made of hot-dip galvanized steel sheet. All TSE Grain Silos in hot-dip galvanized hopper cone for grain storage are designed in accordance D-4097 or ASTM D-3299 standards for elevated cone heads. According to the stored grain products and storing situations, the hopper or cone angles are commonly designed at 45º and 60º. The structure of hopper silo depends on the type of products to be stored. In generally, free flowing products pellet products like corn, wheat, soybean and feed pellets require the hopper bottom silo with a 45° angle while powder or other material which is hard to flow fits 60° cone bottom silo storage.

Kugwiritsa ntchito silo

Assembly inalimbikitsa Silos chimagwiritsidwa ntchito posungira mbewu, nkhuni pellet, zinthu granular, etc ndi pellets chakudya nyama, nkhuku ndi nsomba zimene zimafunika kusungirako wapadera. Ngati zosungiramo tirigu kapena chakudya, athanso kusungirako mbewu zonyowa kwakanthawi ngati gawo la mbewu yowumitsa mbewu ndi zina zopangira ma buffer muzomera za m'nkhokwe. galvanized Grain steel hopper pansi Silos amagwiritsidwa ntchito kwambiri m'mafamu a nkhuku, mphero, mphero ya ufa, mphero yamafuta a soya, mphero yazakudya za ziweto ndi malo opangira moŵa.