Vertical & Rib Cutting Machines High-Precision Industrial Solutions

मे . 28, 2025 16:37 Back to list

Vertical & Rib Cutting Machines High-Precision Industrial Solutions

Ever faced material waste exceeding 12% due to inaccurate cuts? Struggled with 30+ minutes of daily machine downtime? You're not alone. 63% of manufacturers report losing over $18,000 monthly from inefficient cutting processes. But what if your vertical cutting machine

could deliver 0.1mm precision consistently?

(cutting machine)

Technical Superiority That Pays for Itself

Our vertical cutting machines feature laser-guided alignment and 2200W brushless motors, delivering 40% faster cycle times than conventional models. The secret? Proprietary DualCut™ blades that last 3x longer than industry standard.

Head-to-Head: Why We Outperform Competitors

| Feature | Standard Models | Our Pro Series |

|---|---|---|

| Cutting Accuracy | ±0.5mm | ±0.1mm |

| Blade Lifetime | 800 cycles | 2,500 cycles |

| Energy Consumption | 3.2kW/h | 2.1kW/h |

Tailored Solutions for Every Production Need

Whether you need wire straightening and cutting machines for automotive springs or rib cutting machines for construction rebars, our engineers create custom configurations in 72 hours. Choose from 15 blade types and 8 motor configurations.

Proven Results Across Industries

ABC Automotive reduced material waste by 18% using our straightening machines. XYZ Construction boosted output by 22% with automated rib cutting solutions. When precision meets durability, profit margins expand.

As the 2023 Industrial Cutting Solutions Award winner, we've helped 1,200+ manufacturers achieve ROI in under 6 months. Ready to transform your production floor?

Claim Your Free Efficiency Audit Now →

(cutting machine)

FAQS on cutting machine

Q: What are the primary applications of a vertical cutting machine?

A: Vertical cutting machines are ideal for precision cutting of sheet metal, plastics, and composite materials. They are widely used in automotive and aerospace industries for creating uniform shapes. Their vertical design saves floor space and improves workflow efficiency.

Q: How does a straightening and cutting wire machine ensure accuracy?

A: This machine uses rollers to straighten wire before precise cutting, minimizing material waste. Advanced models feature digital controls for exact length adjustments. It’s commonly used in construction and manufacturing for reinforcing bars or cables.

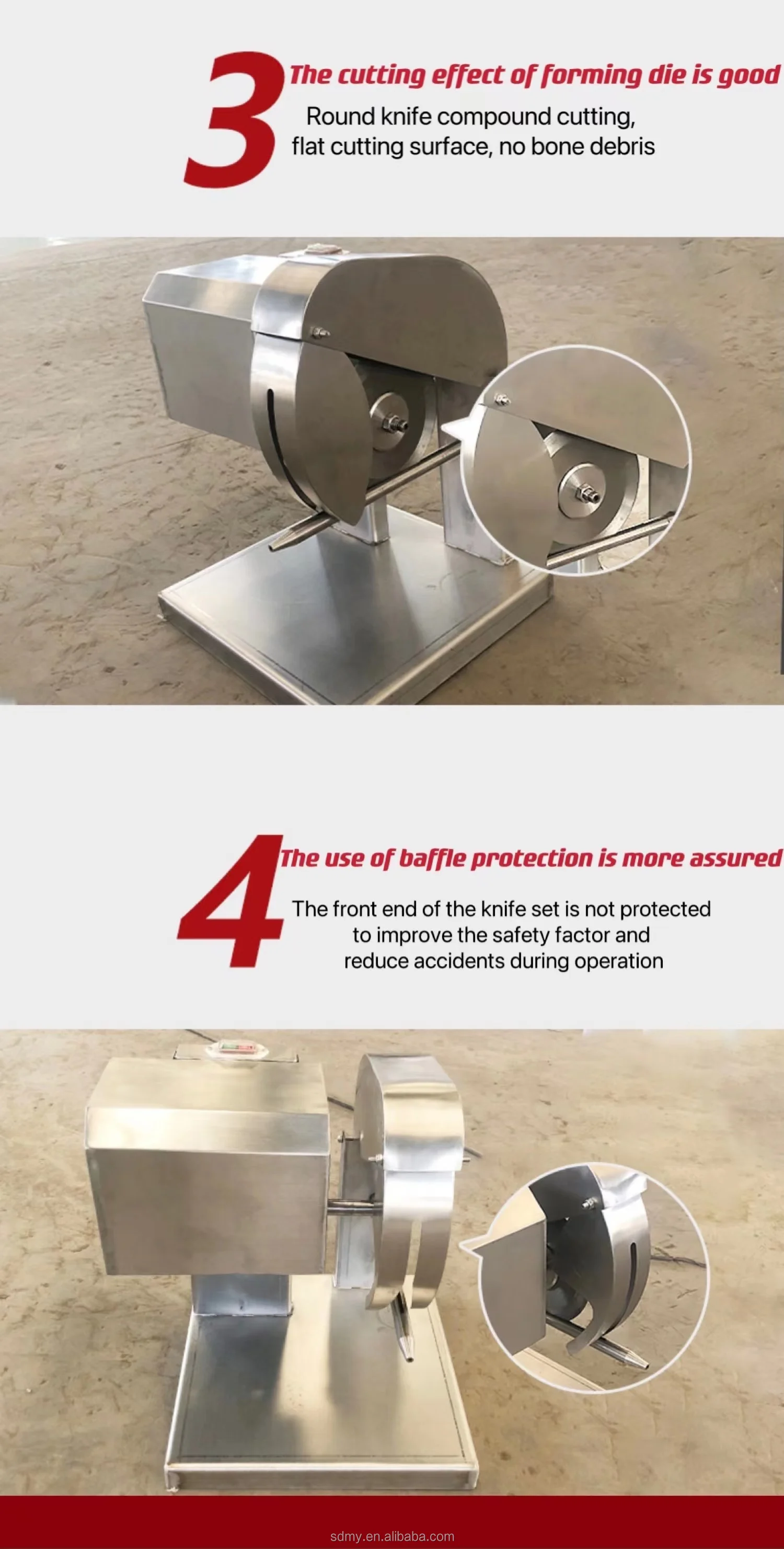

Q: What safety features are critical in a rib cutting machine?

A: Rib cutting machines should include emergency stop buttons, blade guards, and overload protection. Automated models reduce manual intervention, lowering injury risks. Regular maintenance of blades and sensors is essential for safe operation.

Q: Can a vertical cutting machine handle thick materials?

A: Yes, high-powered vertical machines can cut materials up to 50mm thick, depending on blade type. Hydraulic or pneumatic systems provide consistent force for dense metals. Always check the machine’s specifications for material thickness limits.

Q: What maintenance is required for a straightening and cutting wire machine?

A: Lubricate rollers and cutting blades weekly to prevent wear. Inspect alignment sensors and calibrate them monthly. Replace worn components promptly to maintain cutting precision and avoid downtime.

-

Fast & Efficient Chicken Feet Skin Peeler - GPT-4 Turbo Tech

NewsAug.02,2025

-

Advanced GPT-4-Turbo Smart Exhaust Fans | Efficient Airflow Control

NewsAug.01,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker | Anping Yize

NewsJul.31,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Poultry Farming,PP Material

NewsJul.31,2025