Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

Sep . 23, 2025 06:35 Back to list

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

In modern poultry farming, automation has become a cornerstone of efficiency, hygiene, and productivity. The Automatic Feeding Line System—specifically the Pan Feeder Nipple Drinker—stands out as a critical innovation. Designed to streamline feed and water distribution, this system ensures optimal conditions for broiler growth while reducing labor costs. This article delves into the product's features, technical specifications, applications, and the company behind it, supported by authoritative references and detailed visuals.

Product Overview

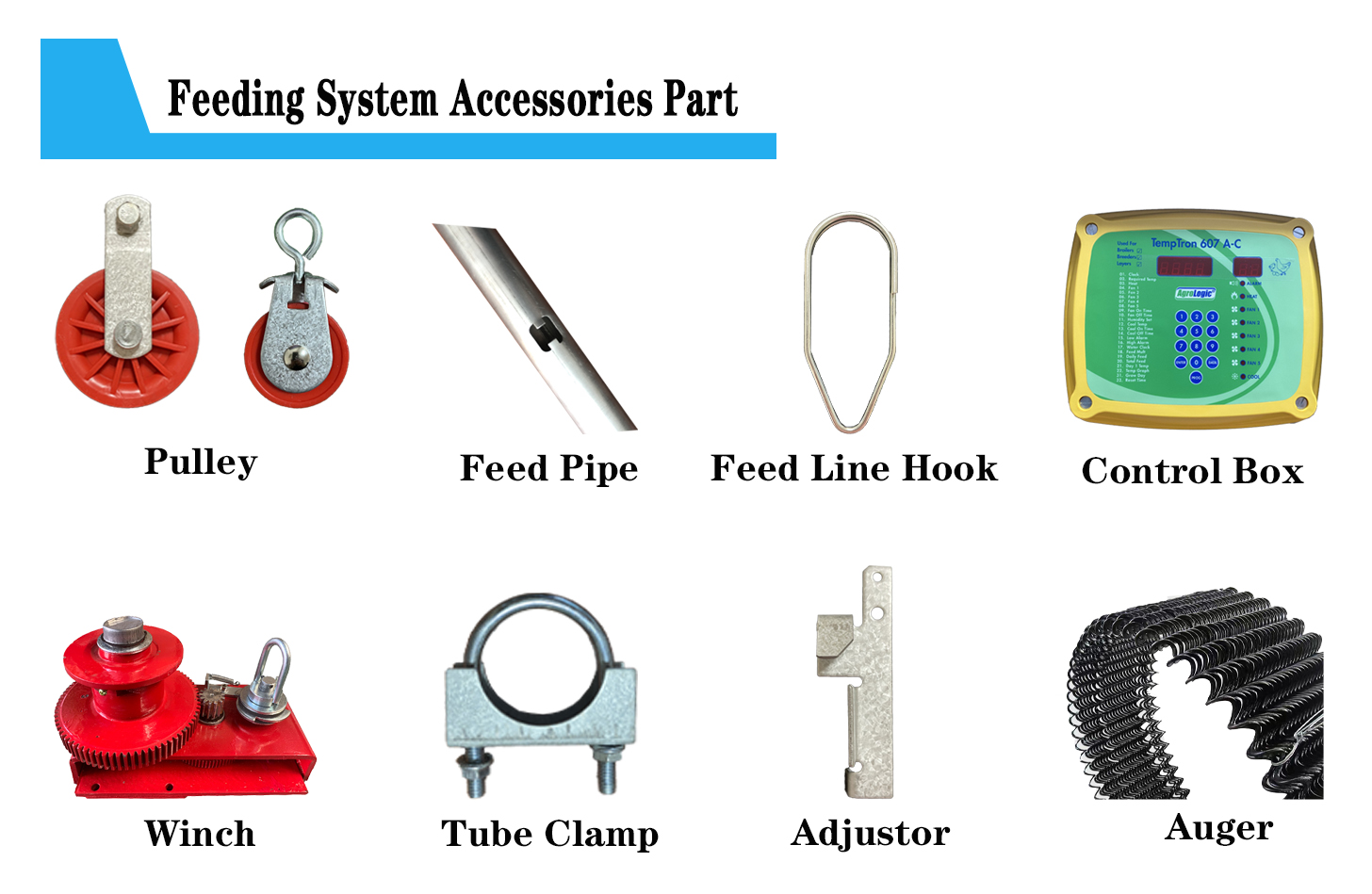

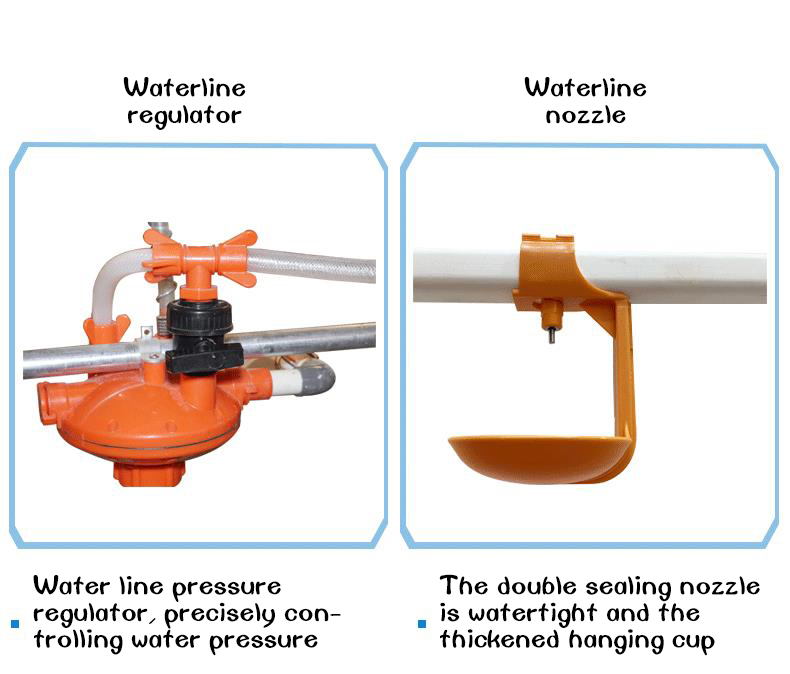

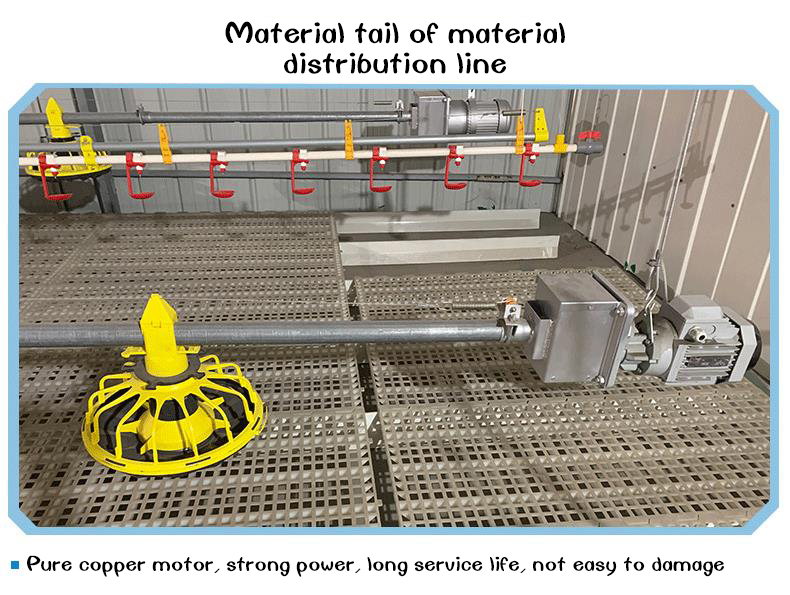

The Automatic Feeding Line System is a comprehensive solution for poultry farms, integrating pan feeding lines, nipple drinking lines, and environmental control systems. This system is engineered to provide consistent feed and water supply, promoting healthy growth and reducing manual intervention. Its design prioritizes durability, ease of maintenance, and adaptability to varying farm sizes and layouts.

Figure 1: Advanced design of the automatic drinking line system.

Key Features and Advantages

- Simple Structure for Easy Maintenance: The system’s modular design simplifies installation and upkeep, minimizing downtime and operational complexity.

- Durable Material with Anti-Aging Formula: Constructed from high-quality polypropylene (PP) with an anti-aging formulation, the system ensures a long lifespan even under harsh farm conditions.

- Specialized for Chicken Farming: Tailored for broiler and layer chickens, the system optimizes feed and water distribution to meet the specific needs of poultry.

Figure 2: Integration of breeding environment equipment for optimal conditions.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Pure Polypropylene (PP) with anti-aging additives |

| Design | Modular, scalable for various farm sizes |

| Applications | Broiler and layer chicken farming |

| Key Components | Pan feeding lines, nipple drinkers, ventilation systems, cooling pads |

| Environmental Control | Integrated systems for temperature and humidity regulation |

Applications in Poultry Farming

The Automatic Feeding and Watering Line is a game-changer in broiler farming. By ensuring a consistent supply of feed and water, it reduces stress on poultry, enhances growth rates, and minimizes feed waste. The system’s precision control over hydration and diet improves overall flock performance, making it a vital tool for modern farmers.

Figure 3: Efficient feed distribution in a broiler farm setup.

Choosing the Right System

Selecting an automatic feeding and watering system requires careful consideration of factors such as farm size, layout, budget, and environmental conditions. Farmers should prioritize systems that offer scalability, energy efficiency, and robust manufacturer support. The Automatic Feeding Line System by Anping County Yize Metal Products Co., Ltd. exemplifies these qualities, ensuring long-term value and reliability.

Company Background: Anping County Yize Metal Products Co., Ltd.

Based in Hebei Province, Anping County Yize Metal Products Co., Ltd. is a leading manufacturer of agricultural and industrial equipment. With a focus on innovation and quality, the company provides solutions that address the evolving needs of modern farming. Their expertise in designing durable, user-friendly systems has earned them a reputation for excellence in the industry.

Figure 4: Detailed components of the feeding line system.

Complementary Products and Services

Anping County Yize Metal Products Co., Ltd. offers a range of related products, including automatic drinking lines, ventilation systems, and cooling pads. Their one-stop service ensures that farmers can access all necessary equipment for a fully automated farm. Additional services include installation support, training, and maintenance, further enhancing the user experience.

Figure 5: Integration of cooling and ventilation systems.

Environmental and Economic Impact

By reducing manual labor and optimizing resource use, the Automatic Feeding Line System contributes to sustainable farming practices. According to the National Institute of Standards and Technology (NIST), automation in agriculture can improve efficiency by up to 30% while reducing waste. This aligns with global efforts to enhance food production sustainability, as highlighted in NIST’s AgriTech Innovation Guidelines (2023).

Reference: National Institute of Standards and Technology (NIST). (2023). AgriTech Innovation Guidelines. Retrieved from https://www.nist.gov/

Figure 6: Advanced environmental control mechanisms.

Conclusion

The Automatic Feeding Line System by Anping County Yize Metal Products Co., Ltd. represents a significant advancement in poultry farming technology. With its durable construction, user-friendly design, and comprehensive features, it addresses the challenges of modern agriculture. As the industry moves toward automation, this system exemplifies the potential for innovation to drive efficiency, sustainability, and profitability in farming operations.

Figure 7: Full-scale implementation of the feeding and drinking system.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025