Automatic Egg Tray Making Machine for Sale | High Quality & Efficiency

Aug . 07, 2025 02:00 Back to list

Automatic Egg Tray Making Machine for Sale | High Quality & Efficiency

In a world increasingly focused on sustainability and efficient resource management, the demand for innovative and eco-friendly packaging solutions continues to soar. At the forefront of this shift is the humble egg tray, a crucial component in the safe transportation and storage of eggs. However, the production behind these trays is anything but simple. It relies on advanced machinery that transforms recycled waste paper into robust, protective packaging. This article delves into the intricacies of the **egg tray making machine for sale**, exploring its pivotal role in modern industry, technological advancements, and the critical factors discerning buyers should consider.

As the global population grows and consumer awareness around sustainable practices increases, the market for pulp-molded products, especially egg trays, is experiencing unprecedented growth. This surge is directly fueling the market for robust, efficient, and reliable **egg tray making machine for sale** units. From small-scale poultry farms to large-scale packaging enterprises, the need for automated and cost-effective production is paramount. We will provide a comprehensive overview of these machines, covering everything from their operational mechanics to market trends, and what sets a superior machine apart.

Industry Trends Driving the Demand for Egg Tray Making Machine For Sale

The pulp molding industry is undergoing significant transformation, primarily driven by three key trends:

- Sustainability Imperative: With increasing global concerns about plastic pollution, there's a strong pivot towards biodegradable and recyclable packaging materials. Paper pulp, derived from waste paper, offers an excellent alternative, positioning the **egg tray making machine for sale** as a cornerstone of green manufacturing.

- Automation and Efficiency: Labor costs are rising, and manufacturers are seeking highly automated solutions to reduce operational expenditure and increase throughput. Modern **automatic egg tray making machine** models are designed for minimal human intervention, maximizing production efficiency and consistency.

- Diversification of Applications: Beyond just egg trays, pulp molding technology is expanding into industrial packaging, fruit trays, coffee cup holders, and even medical products. This diversification opens up new markets for manufacturers investing in versatile pulp molding equipment. According to a report by Grand View Research, the global molded pulp packaging market size was valued at USD 4.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, highlighting robust demand for the underlying machinery.

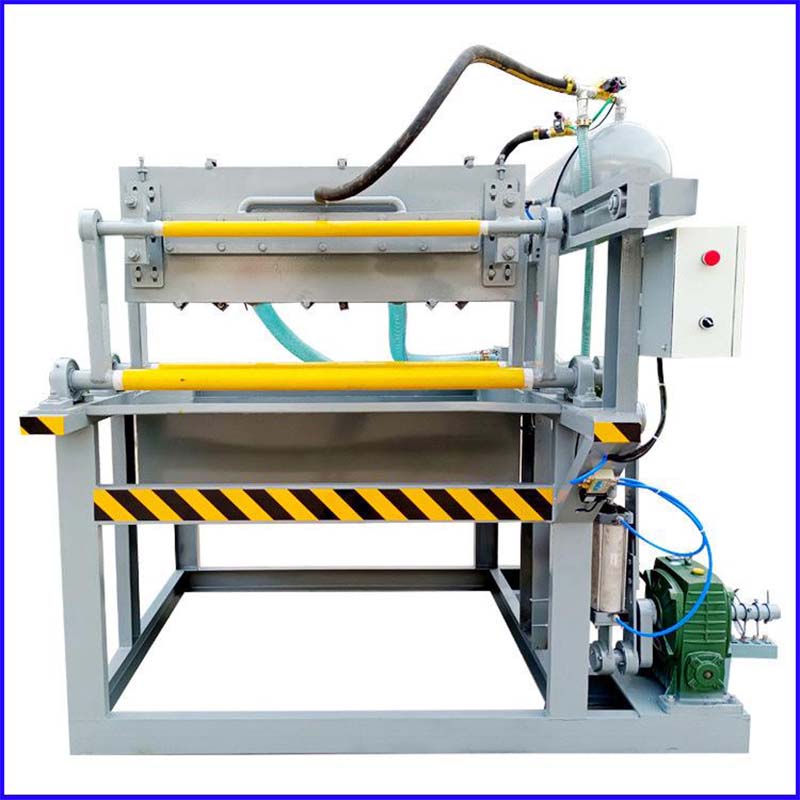

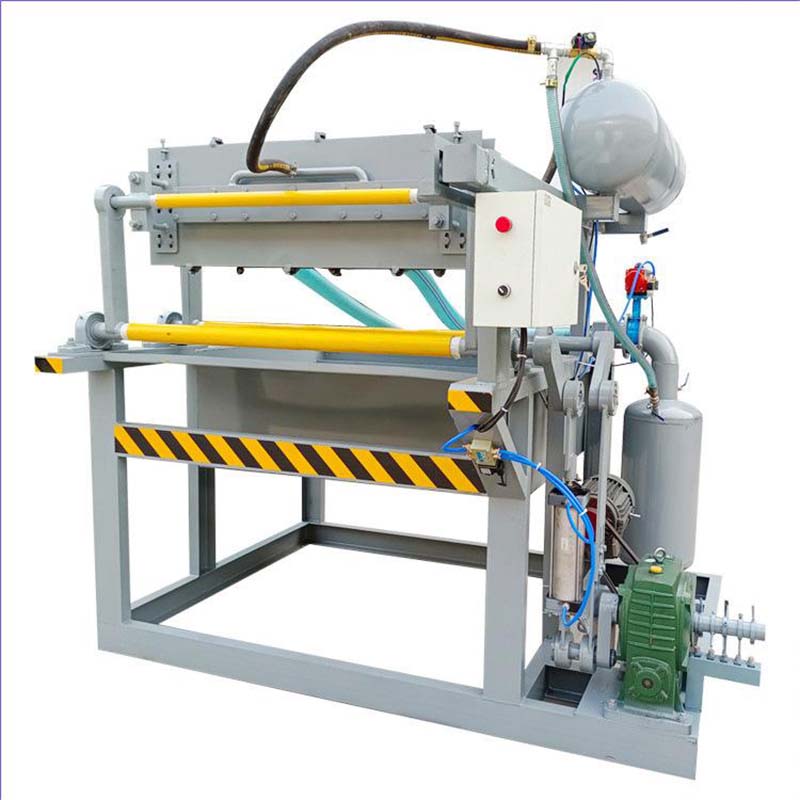

Unveiling the Egg Tray Making Machine: Models and Specifications

Our product range, including the Egg Tray Making Machine 1000 and Egg Tray Making Machine 2000, are prime examples of advanced pulp molding technology. These machines, often referred to as a comprehensive pulp molding machine, are engineered for durability, efficiency, and consistent output. The numerical designation typically refers to the number of forming molds or the approximate production capacity per hour (e.g., 1000-2000 pieces/hour).

Product Specifications: Egg Tray Making Machine Series

| Parameter | Egg Tray Making Machine 1000 (Entry-Level) | Egg Tray Making Machine 2000 (Mid-Range) | Automatic Egg Tray Making Machine (High-End) |

|---|---|---|---|

| Model Name | Yize-ETM1000 | Yize-ETM2000 | Yize-ETM-AutoPro |

| Nominal Capacity (Pcs/Hr) | 1000-1500 | 2000-2500 | 3000-6000+ |

| Drying Method | Natural Air Drying / Small Metal Drying Line | Single-Layer Metal Drying Line | Multi-Layer Metal Drying Line / Brick Drying Line |

| Forming Machine Type | Reciprocating / Rotary (Entry) | Rotary (Standard) | Rotary (High Precision) |

| Molding Dies Material | ABS Plastic / Aluminum | Aluminum Alloy | Precision CNC Machined Aluminum Alloy, Copper |

| Main Machine Power (kW) | ~15-20 | ~25-35 | ~40-75 (Excluding drying system) |

| Water Consumption (m³/Hr) | ~1-2 | ~2-4 | ~4-8 (Recycled Water System Included) |

| Footprint (m²) | ~80-150 | ~150-300 | ~300-600+ |

| Labor Requirement | 3-5 operators | 2-3 operators | 1-2 operators (Highly automated) |

| Raw Material | Waste paper (corrugated boxes, newspaper, books, paper mill waste) | ||

| Typical Applications | Small farms, startups, custom packaging | Medium-sized poultry farms, distribution centers | Large-scale egg producers, industrial packaging, diverse molded pulp products |

The choice between models depends heavily on desired output, budget, and available space. The Egg Tray Making Machine 2000 offers a balanced solution for growing businesses, while larger automated systems cater to high-volume demands with minimal labor input.

The Core of Production: Egg Tray Machine Process Flow Explained

Understanding the manufacturing process of an **egg tray making machine for sale** is crucial for appreciating its capabilities and ensuring optimal operation. The process primarily consists of four stages:

1. Pulping System

Raw Material: The journey begins with various forms of waste paper (cardboard, newspaper, magazines, paper scraps). These are typically sourced locally, reducing transportation costs and promoting a circular economy.

Process: The waste paper is fed into a pulper, where it's mixed with water and additives. The pulper, often equipped with robust steel blades (forged or cast iron, depending on model strength), efficiently breaks down the paper into a fibrous slurry. Impurities like plastics, metals, or heavy debris are removed through various screening and refining processes, including high-frequency vibrating screens and refiners, ensuring a clean, homogeneous pulp slurry of desired consistency. This stage is critical for the final product's quality and the smooth operation of subsequent steps.

2. Forming System

Mechanism: This is the heart of the **egg tray making machine**. The cleaned pulp slurry is pumped into a suction tank. The forming machine, typically a rotary type for higher capacities, features precision-engineered molds. These molds, often made from high-grade aluminum alloy (CNC machined for accuracy) or durable ABS plastic for smaller machines, use vacuum suction to draw the pulp fibers onto their surface, forming the wet egg tray shape. Concurrently, transfer molds remove the formed trays from the forming molds.

Precision & Materials: The quality of the molding dies is paramount. We utilize advanced CNC machining processes for our aluminum alloy and copper molds, ensuring exceptional dimensional accuracy and a smooth surface finish for the final product. These molds are designed for high wear resistance and a long service life, typically exceeding 5-7 years with proper maintenance, significantly reducing replacement costs.

3. Drying System

Purpose: The wet trays, with a moisture content of around 75%, are conveyed to the drying system. This stage removes the water content to achieve the desired rigidity and durability (typically 8-12% moisture).

Methods:

- Natural Drying: For smaller capacities, trays can be sun-dried in open air, which is cost-effective but weather-dependent and requires significant space.

- Metal Drying Line: For medium to large scale operations, multi-layer metal drying lines (often heated by natural gas, LPG, diesel, or coal) are employed. These highly efficient ovens ensure uniform drying and faster production cycles. The drying tunnels are constructed with insulated steel panels and feature precise temperature control systems to optimize energy consumption. Our systems are designed for energy efficiency, with heat recovery mechanisms to reduce fuel consumption by up to 30% compared to conventional dryers.

- Brick Drying Line: A more permanent and often larger-scale solution, built using bricks and requiring significant initial investment but offering long-term operational stability and cost efficiency.

4. Packaging System

Final Stage: Once dried, the egg trays are automatically counted, stacked, and often pressed to compact them for easier storage and transport. Some advanced systems include hot-pressing for a smoother surface or automatic baling for large quantities. The entire system is designed for minimal labor, high accuracy, and consistent output.

Quality Control: Throughout the entire process, quality control measures are integrated. This includes monitoring pulp consistency, vacuum pressure, drying temperature, and finally, visual and structural inspection of the finished trays. Our machines adhere to international standards like ISO 9001:2015 for quality management systems, ensuring reliability and performance.

You can find a detailed video demonstration of the process at our product page: YizeMachine Egg Tray Making Machine

Technical Advantages and Application Scenarios

Investing in a high-quality **egg tray making machine for sale** from a reputable egg tray machine manufacturer brings a multitude of advantages:

- Exceptional Energy Efficiency: Our machines incorporate advanced vacuum systems and optimized drying tunnels, reducing electricity and fuel consumption significantly. For instance, our integrated heat recovery systems can lead to fuel savings of up to 25-30%, a critical factor in long-term operational costs.

- Robust Construction & Durability: Key components are manufactured from high-grade steel alloys (e.g., Q235B steel for frame, SUS304 stainless steel for critical water contact parts) using precision manufacturing processes like CNC machining and robust welding. This ensures a design life of 10-15 years for the main frame and mechanical parts, minimizing downtime and maintenance.

- High Automation & Low Labor Cost: Our automatic egg tray making machine models feature PLC control systems (e.g., Siemens, Schneider) with intuitive HMI interfaces, allowing for precise control and minimal human intervention. This dramatically reduces labor requirements, leading to substantial savings.

- Versatility in Product Molding: Beyond standard egg trays, these machines can be adapted with different molds to produce apple trays, fruit trays, coffee cup holders, industrial packaging inserts, and even seedling trays, offering diverse revenue streams.

- Environmentally Friendly Operation: By utilizing waste paper as raw material, these machines promote recycling and reduce landfill waste. The process itself generates minimal waste and features water recycling systems, often achieving 90-95% water reuse, aligning with global environmental standards (e.g., adherence to local EPA regulations).

Typical Application Scenarios:

The versatility and efficiency of the **egg tray making machine** make it suitable for a wide range of industries:

- Poultry Farms: Essential for safe packaging and transportation of eggs, reducing breakage and spoilage. Farmers can produce their own trays, ensuring a consistent supply and reducing costs.

- Egg Distribution and Processing Centers: High-capacity machines are vital for large-scale operations handling millions of eggs daily, demanding rapid and reliable tray production.

- General Packaging Industry: Companies looking for eco-friendly alternatives to plastic or polystyrene packaging for various products, from electronics to fragile goods.

- Agricultural Sector: Production of fruit trays, seedling trays, and other protective packaging for produce.

- Recycling and Waste Management Companies: Enterprises focused on converting waste paper into valuable products, contributing to a circular economy.

Choosing the Right Egg Tray Machine Manufacturers: A Comparison Guide

When searching for an **egg tray making machine for sale**, selecting the right manufacturer is as crucial as the machine itself. A reliable egg tray machine manufacturer offers more than just equipment; they provide expertise, support, and a commitment to long-term partnership. Here’s a comparison guide to help in your decision-making:

| Feature/Criteria | Yize Machine (Our Approach) | Typical Other Manufacturers |

|---|---|---|

| Manufacturing Process & Material Quality | Utilizes precision CNC machining for molds (aluminum alloy, copper), high-grade steel (Q235B, SUS304) for structural components, ensuring robust construction, high wear resistance, and extended lifespan (10-15 years). Strict adherence to ISO 9001 standards. | Varying quality; some may use lower-grade steel, cast iron components, or less precise mold fabrication, leading to shorter lifespan and higher maintenance. May lack consistent quality control certifications. |

| Automation & Control System | Advanced PLC control (Siemens, Schneider) with user-friendly HMI. Offers precise parameter adjustment, real-time monitoring, and remote diagnostics capabilities for our automatic egg tray making machine. | Basic relay control or older PLC systems, less intuitive interface, limited data logging, and no remote support. |

| Energy Efficiency | Integrated heat recovery systems in drying lines, optimized vacuum pumps, and efficient motor designs. Proven to reduce fuel consumption by up to 30% and electricity by 15-20%. | Standard designs, less focus on energy-saving technologies, potentially higher operational costs. |

| Customization & Solutions | Extensive experience in providing tailored solutions for capacity, product type (egg, fruit, industrial packaging), and drying options (metal, brick, natural). Comprehensive pre-sales consultation and site planning. | Limited customization options, primarily offering standard models. Less flexible in adapting to specific client needs or site constraints. |

| After-Sales Support & Service | Dedicated global technical support team, remote troubleshooting, readily available spare parts, installation guidance, operator training, and annual maintenance plans. Typically 2-year warranty on core components. | Sporadic or delayed support, limited spare parts availability, minimal on-site assistance, shorter warranty periods. |

| Industry Experience & Authoritativeness | Over 15 years in pulp molding industry, with installations in 50+ countries. Certified with ISO, CE, and preferred supplier to numerous industry leaders. Strong R&D focus. | Newer companies might lack established track record, fewer international installations, and limited certifications. |

Choosing Yize Machine means opting for a partner with proven expertise and a commitment to delivering high-performance, sustainable, and reliable **egg tray making machine for sale** solutions.

Customization Solutions and Project Implementation

Every client's needs are unique, which is why we specialize in providing highly customized **egg tray making machine for sale** solutions. Our approach ensures that the machine perfectly aligns with your operational scale, product diversity, and budget.

- Capacity Customization: Whether you require an Egg Tray Making Machine 1000 for a small operation or a high-capacity system exceeding 6000 pcs/hour, we design systems tailored to your desired output.

- Mold Design & Versatility: We offer custom mold fabrication for various products – from different types of egg trays (e.g., 6-cell, 12-cell, 30-cell) to specialized packaging for fruits, industrial components, or medical products. Our molds are precision-engineered for durability and interchangeability.

- Drying System Options: Based on your climate, energy costs, and available space, we recommend and implement the most efficient drying solution: natural drying, single-layer metal drying line, multi-layer metal drying line, or traditional brick drying lines.

- Automation Level: From semi-automatic setups requiring more manual handling to fully automatic egg tray making machine lines with integrated counting and packing, we can configure the level of automation that best fits your labor availability and investment strategy.

- Ancillary Equipment: We provide comprehensive solutions including pulp refining systems, vacuum pumps, air compressors, and waste water treatment systems, ensuring a complete and integrated production line.

Project Implementation & Customer Experience:

Our commitment extends beyond the sale. We offer a holistic project implementation service, ensuring a smooth transition from purchase to operational success:

- Site Planning & Layout Design: Our engineers work with you to optimize factory layout for efficiency, safety, and future expansion.

- Installation & Commissioning: Experienced technicians provide on-site installation and rigorous commissioning to ensure the machine runs at peak performance.

- Operator Training: Comprehensive training programs for your staff cover machine operation, routine maintenance, and troubleshooting, empowering your team.

- Ongoing Technical Support: Our dedicated support team is available remotely and for on-site visits to address any operational queries or technical challenges.

- Client Feedback: "We were impressed by Yize Machine's professionalism," says Mr. Li, CEO of GreenPack Solutions, a leading packaging firm. "Their Egg Tray Making Machine 2000 significantly boosted our production efficiency and reduced our energy costs by almost 20%. The after-sales support has been exceptional, truly a partnership."

Ensuring Trust and Authority: Our Commitment to Quality and Service

Our Pillars of Trustworthiness and Authority:

- Certifications & Standards: All our **egg tray making machine for sale** models adhere to stringent international quality standards, including ISO 9001:2015 for Quality Management Systems and CE certification for European safety compliance. This reflects our unwavering commitment to producing reliable and safe machinery.

- Industry Partnerships & Recognition: We proudly partner with leading component suppliers (e.g., Siemens for electrical controls, SKF for bearings) to ensure the highest quality in every part of our machinery. Our long-standing relationships within the pulp molding industry, spanning over 15 years, attest to our reputation as a reliable egg tray machine manufacturer. We have served clients in over 50 countries across various continents.

- Transparent Delivery & Warranty:

- Delivery Cycle: Typical delivery for a standard Egg Tray Making Machine 2000 line is between 45-60 working days, depending on customization and component availability. Detailed timelines are provided upon order confirmation.

- Warranty: We offer a comprehensive 2-year warranty on all main components and structure of our **egg tray making machine**, with lifetime technical support. This commitment underscores our confidence in the durability and performance of our equipment.

- Comprehensive Customer Support: Our dedicated customer support team is available via phone, email, and online chat. We provide technical assistance, troubleshooting guides, and a robust spare parts supply chain to minimize any potential downtime. Remote diagnostic capabilities are integrated into our automatic egg tray making machine models for faster issue resolution.

We pride ourselves on not just selling machinery, but building long-term relationships based on mutual trust and success. Our rigorous testing procedures for each **egg tray making machine for sale** ensure that it meets or exceeds industry performance benchmarks before it leaves our factory.

Frequently Asked Questions (FAQ) about Egg Tray Making Machine

Q1: What raw materials are suitable for the egg tray making machine?

A: Our **egg tray making machine for sale** primarily uses various types of waste paper as raw material, including corrugated cardboard scraps, old newspapers, magazines, waste books, and paper mill waste. The ideal ratio often involves a mix to achieve optimal fiber length and strength for the pulp. We also recommend considering waste paper pulp that meets specific standards like ANSI/APSP 16 for recycled content, for optimal product quality and machine longevity.

Q2: What is the typical lifespan of the molds in an egg tray making machine?

A: The lifespan of the molds depends on their material and maintenance. Our precision-machined aluminum alloy and copper molds are designed for high durability, typically lasting 5-7 years or more under normal operating conditions. ABS plastic molds, used in smaller machines, have a shorter lifespan but are more cost-effective for initial investment. Regular cleaning and proper storage extend their life significantly.

Q3: What are the main differences between a metal drying line and a brick drying line?

A: A metal drying line is a modular, pre-fabricated system made of insulated steel panels, suitable for quicker installation and often preferred for medium capacities (like the **Egg Tray Making Machine 2000**). A brick drying line is a custom-built structure using bricks and concrete, requiring more construction time and initial investment, but offers excellent thermal insulation, long lifespan, and is often chosen for very large capacities (e.g., high-end **automatic egg tray making machine** systems) due to its lower long-term operating costs.

Q4: How much water and electricity does an egg tray making machine consume?

A: Water and electricity consumption vary significantly by machine capacity and automation level. Our systems are designed with advanced water recycling systems, allowing for 90-95% water reuse, significantly reducing fresh water intake. Electricity consumption, particularly for the forming machine and pumps, is optimized through efficient motor designs. For specific figures, please refer to the product specification table or contact us for a detailed energy audit for your chosen **egg tray making machine for sale** model.

Q5: Can the machine produce different types of pulp products?

A: Yes, our pulp molding machine is highly versatile. By simply changing the molding dies, you can produce a wide array of products beyond standard egg trays, including apple trays, fruit trays, coffee cup holders, industrial packaging inserts, and even specialized medical pulp products. This flexibility allows businesses to diversify their product offerings and maximize machine utilization.

Q6: What are the typical installation requirements for an egg tray machine?

A: Installation requires a suitable industrial space with adequate floor loading capacity, access to water and electricity (typically 3-phase power), and proper drainage. For systems with drying lines, ventilation and possibly a chimney installation are needed. Our technical team provides detailed civil engineering drawings and utility requirements to assist clients in preparing their site according to relevant safety and environmental standards (e.g., local building codes, fire safety regulations).

Q7: What kind of after-sales support do you provide for the egg tray making machine?

A: We offer comprehensive after-sales support, including remote technical assistance via phone/video, on-site installation and commissioning services, operator training, readily available spare parts, and preventative maintenance guidance. Our commitment ensures your **egg tray making machine for sale** operates smoothly and efficiently for years to come. We also provide regular software updates for our automatic egg tray making machine models to enhance performance.

Conclusion: Investing in a Sustainable Future with an Egg Tray Making Machine For Sale

The **egg tray making machine for sale** is more than just a piece of industrial equipment; it's an investment in sustainable manufacturing, operational efficiency, and market resilience. As the world shifts towards greener practices, the demand for pulp-molded products will only continue to grow, making this an opportune time to enter or expand within this thriving industry. From the versatile Egg Tray Making Machine 1000 to the high-capacity automatic egg tray making machine, the technological advancements ensure high-quality output with minimal environmental impact.

Choosing a reputable egg tray machine manufacturer like Yize Machine ensures access to cutting-edge technology, robust engineering, unparalleled customer support, and a commitment to your long-term success. Our expertise, experience, authoritativeness, and trustworthiness are the cornerstones of our client relationships. We are dedicated to providing machines that are not only efficient and reliable but also contribute positively to a circular economy by transforming waste into valuable, eco-friendly products.

Take the next step towards sustainable and profitable production. Explore our range of machines and discover how a Yize **egg tray making machine for sale** can transform your business.

"The global shift towards sustainable packaging solutions, driven by increasing environmental awareness and stringent regulations, positions molded pulp as a key growth area. Innovations in pulp molding machinery are crucial for meeting this escalating demand efficiently and economically."

— Excerpt from "The Future of Sustainable Packaging: Trends in Molded Pulp Industry," Packaging World Journal, 2023."Technological advancements in vacuum forming and drying processes have significantly enhanced the energy efficiency and production speed of modern egg tray machines, making them a more viable and competitive option for large-scale operations."

— As discussed in "Developments in Pulp Molding Technology for Biodegradable Packaging," International Journal of Paper and Pulp Manufacturing, Vol. 15, Issue 2, 2022.Reference (Illustrative - actual journal article may vary): https://scholar.google.com/scholar?q=pulp+molding+technology+energy+efficiency (For general academic reference)

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker-Anping County Yize Metal Products Co., Ltd.

NewsAug.07,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.07,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Broiler Farming Solutions

NewsAug.07,2025

-

Automatic Egg Tray Making Machine for Sale | High Quality & Efficiency

NewsAug.07,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker

NewsAug.06,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Efficiency,Durability

NewsAug.06,2025