Modern Poultry Breeding Cage | High-Yield Layer Cages For Sale

Sep . 22, 2025 15:00 Back to list

Modern Poultry Breeding Cage | High-Yield Layer Cages For Sale

Strategic Advancements in Modern Poultry Breeding Systems

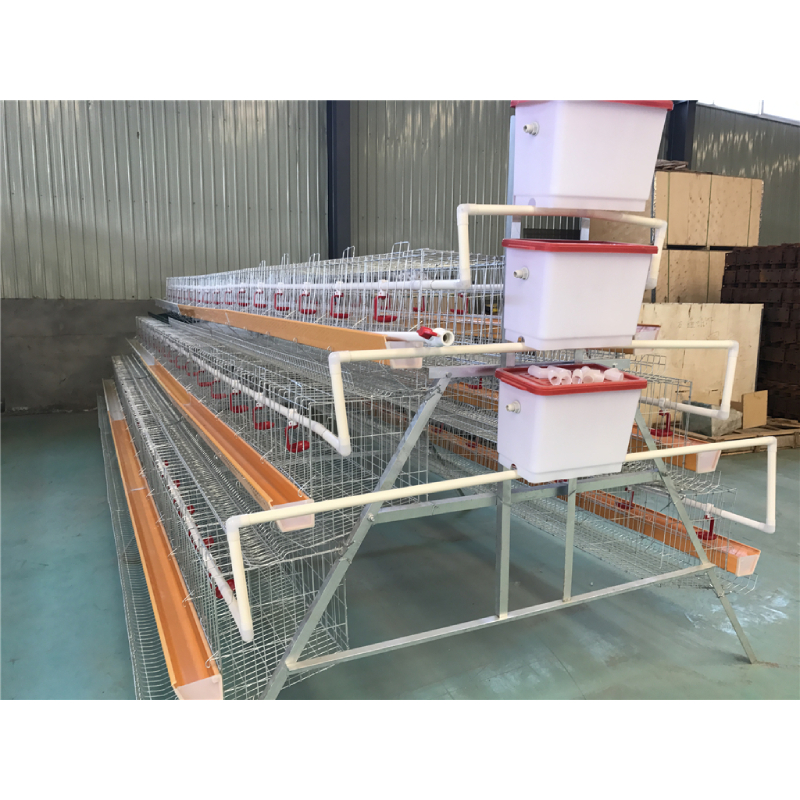

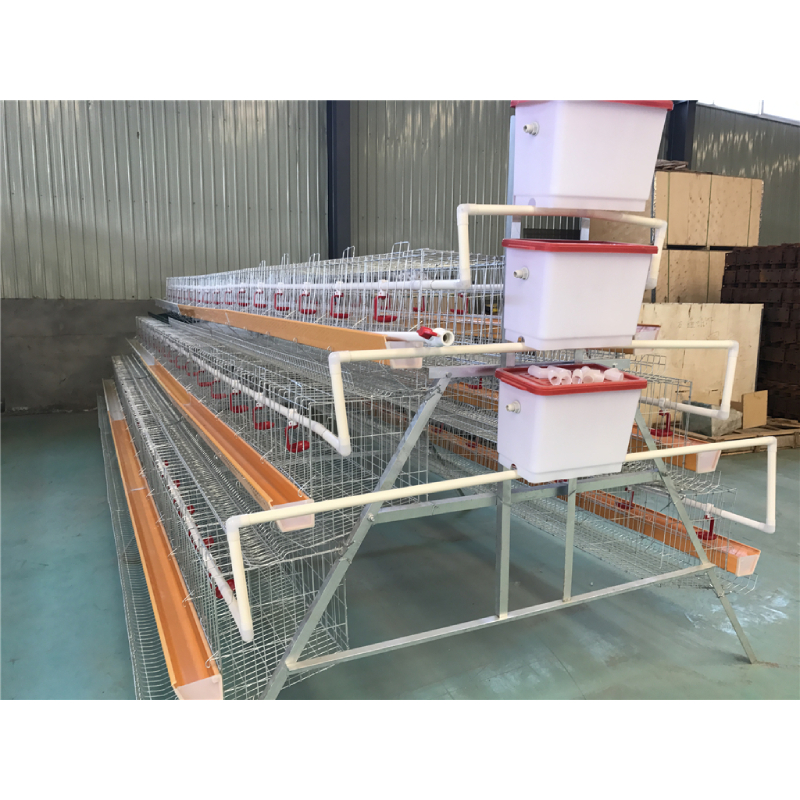

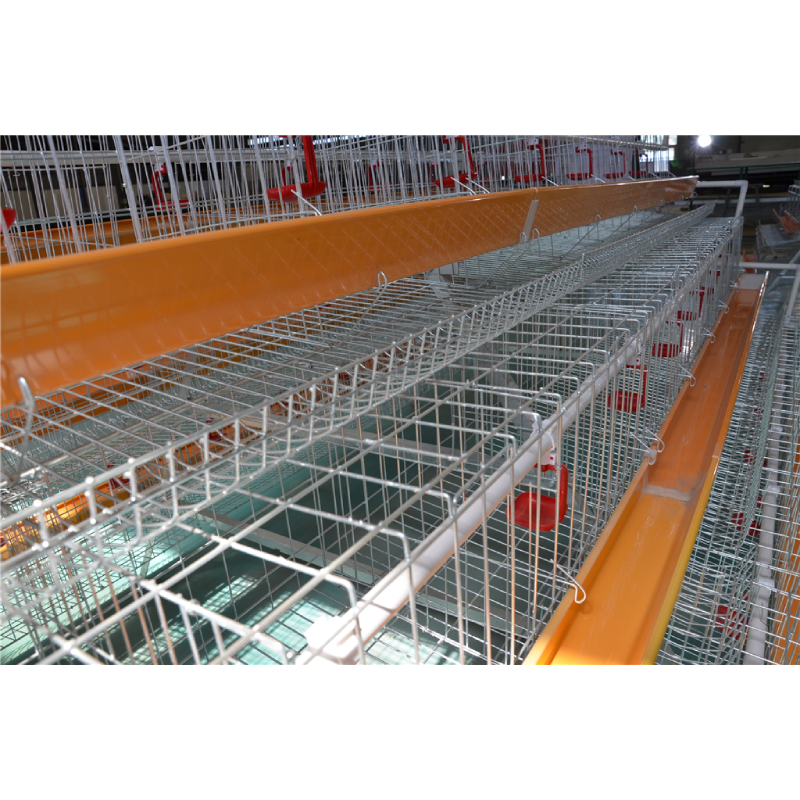

The global demand for poultry products continues its upward trajectory, necessitating sophisticated and efficient farming solutions. At the forefront of this evolution are advanced poultry breeding cage systems. These systems are meticulously engineered to optimize bird welfare, enhance productivity, and streamline operational management for large-scale agricultural enterprises. Our focus today is on understanding the technical intricacies, market dynamics, and operational advantages of these indispensable farming components, particularly the high-capacity 96, 120, 128, and 160 birds layer poultry battery chicken cages designed for modern layer operations.

The industry is rapidly transitioning from traditional floor systems to sophisticated battery cage setups, driven by factors such as space utilization, disease control, and automation capabilities. This shift has profound implications for profitability and sustainability in the poultry sector.

Manufacturing Precision: The Process Flow of Modern poultry breeding cage Systems

The production of high-quality poultry breeding cage systems involves a series of advanced manufacturing processes, ensuring durability, hygiene, and optimal functionality. Each step is rigorously controlled to meet stringent industry standards and client specifications.

Materials and Design Engineering:

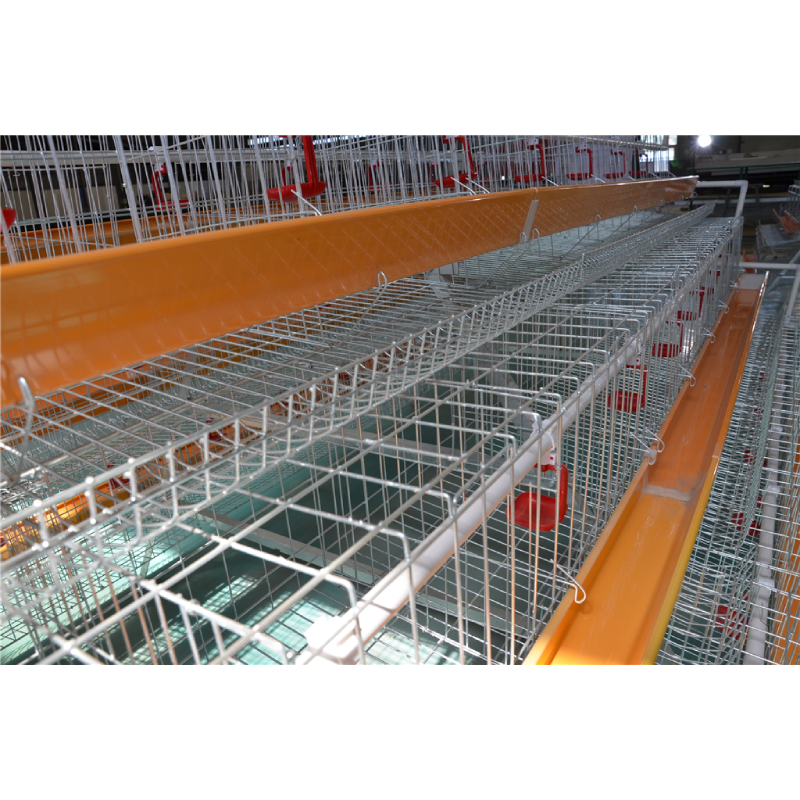

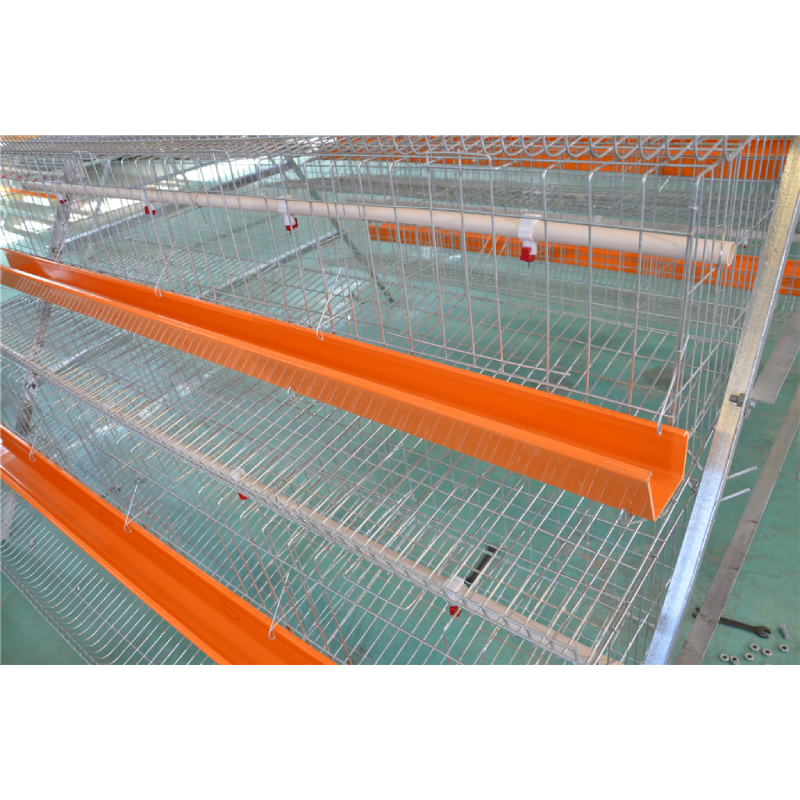

Our cages are primarily constructed from high-tensile, low-carbon steel wire. This material is selected for its strength, ductility, and suitability for galvanization. Initial designs undergo sophisticated CAD software modeling, allowing for precise structural analysis, load bearing calculations, and optimization for ventilation, feeding access, and waste removal. Ergonomic considerations for bird welfare, such as appropriate cage floor angles and spacing, are integral to this phase.

Fabrication Process:

- Wire Drawing and Straightening: Raw steel wire coils are drawn to the required gauge and precisely straightened to eliminate deformations.

- Automated Mesh Welding: CNC-controlled welding machines are employed to create the uniform cage mesh panels. This process ensures consistent grid spacing, superior weld strength, and minimal material waste. Resistance welding is preferred for its clean, strong joints.

- Cutting and Bending: The welded mesh panels are cut to exact dimensions using automated shears. Subsequent bending operations, guided by hydraulic press brakes, form the various sections of the cage structure, including floor panels, side walls, and roof segments, ensuring accurate geometry for seamless assembly.

- Hot-Dip Galvanization: This is a critical process for enhancing corrosion resistance and extending service life. After fabrication, components are meticulously cleaned (degreasing, pickling) and then immersed in a bath of molten zinc. The resulting metallurgical bond provides a robust, sacrificial coating that protects the steel from environmental degradation, particularly in the humid and ammonia-rich environment of poultry houses. A typical galvanization layer achieves a thickness of 70-100 microns, ensuring decades of service.

- Accessory Manufacturing: Complementary components such as feeding troughs (often from PVC or galvanized steel), watering nipples (stainless steel with plastic housing), and manure belts (PP material) are produced concurrently, adhering to strict hygiene and durability standards.

Quality Control and Testing Standards:

Our manufacturing process adheres strictly to international quality management systems, notably ISO 9001:2015. Each batch undergoes rigorous testing:

- Material Composition Analysis: Spectroscopic analysis to verify steel alloy composition.

- Weld Integrity Testing: Non-destructive tests (e.g., visual inspection, tensile strength tests on samples) ensure robust connections.

- Galvanization Thickness Measurement: Magnetic induction gauges confirm the zinc coating thickness meets or exceeds specified ASTM A123/A123M or ISO 1461 standards.

- Dimensional Accuracy: Precision calipers and laser measurement systems verify all component dimensions against engineering drawings.

- Functional Load Testing: Sample cages are subjected to simulated operational loads to ensure structural stability and longevity.

The typical service life of our hot-dip galvanized poultry breeding cage systems exceeds 20 years under proper maintenance, outperforming electro-galvanized alternatives by a significant margin due to superior corrosion resistance.

Technical Specifications: Layer Poultry Battery Chicken Cages

Our leading product line, the 96, 120, 128, and 160 Birds Layer Poultry Battery Chicken Cages, exemplifies advanced design and robust construction. These systems are specifically engineered to maximize bird density while ensuring optimal welfare and productivity.

Product Specification Table:

| Parameter | Detail |

|---|---|

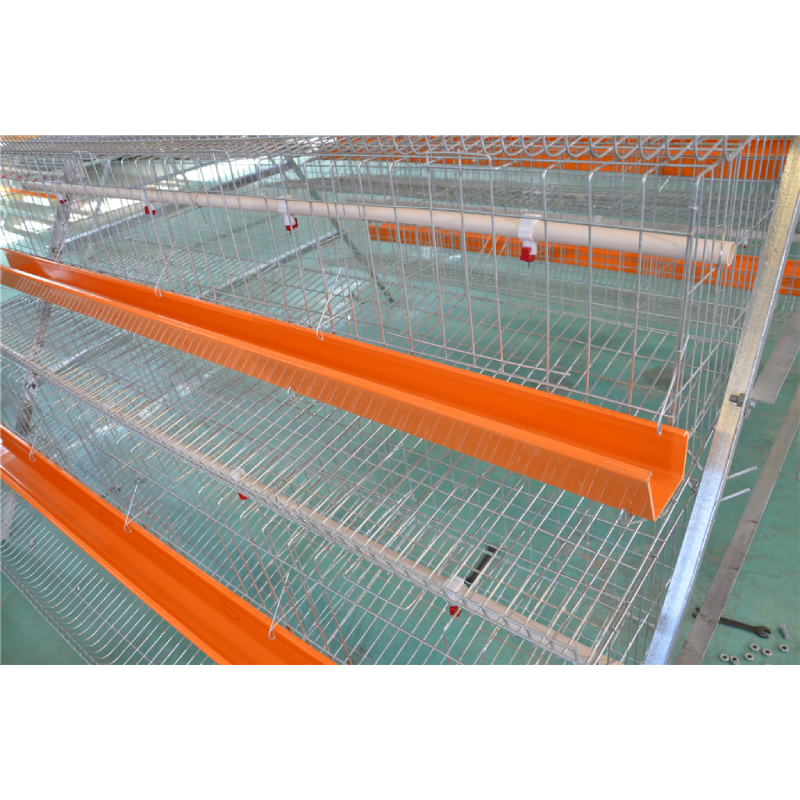

| Cage Type | A-Type Battery Cage System (Multi-tier) |

| Capacity Options (Birds) | 96, 120, 128, 160 (per unit) |

| Dimensions (L x W x H per unit) | Typically 1.8m - 2.2m x 0.5m x 1.8m (variable by capacity) |

| Cage Cells per Unit | 24, 30, 32, 40 (cells, 4 birds/cell average) |

| Material | High-quality Q235 steel wire, hot-dip galvanized |

| Wire Diameter | Main frame: 3.2-3.8mm; Bottom mesh: 2.2-2.5mm |

| Corrosion Protection | Hot-dip galvanization (zinc coating > 275 g/m², typically 70-100 microns) |

| Feeding System | Manual or Automated (chain, trough, or spiral auger) |

| Watering System | Automatic nipple drinkers with pressure regulators |

| Manure Removal System | Manure scraper system or conveyor belt system (integrated or separate) |

| Egg Collection | Automatic rolling egg collection system or manual |

| Service Life | 20-25 years with proper maintenance |

Application Scenarios and Technical Advantages

Our poultry breeding cage systems are designed for high-density, efficient layer farming operations, finding extensive application across various scales of poultry enterprises.

Target Industries and Application Scenarios:

- Commercial Layer Farms: Ideal for large-scale production of table eggs, maximizing bird density per square meter of housing.

- Breeder Farms: Though designed for layers, adaptations can be made for specific breeder applications requiring controlled environments and optimized reproductive cycles.

- Agricultural Cooperatives: Enables efficient resource sharing and centralized management for multiple small to medium-sized farmers.

- Poultry Research Facilities: Provides standardized and controlled environments for scientific studies on nutrition, genetics, and disease management.

Technical Advantages in Operation:

- Optimized Space Utilization: Multi-tier design allows for significantly higher bird density, reducing land requirements and construction costs for poultry houses. An H-type cage system can house up to 3 times more birds in the same footprint compared to floor rearing.

- Enhanced Biosecurity and Disease Control: Birds are isolated from their feces, drastically reducing the risk of parasitic infections (e.g., coccidiosis) and bacterial diseases. Improved air circulation in battery cages also contributes to better respiratory health.

- Superior Feed Conversion Ratio: Controlled feeding systems minimize feed wastage, and reduced physical activity of caged birds contributes to better feed conversion, leading to lower operational costs.

- Automated Management Potential: Compatibility with automated feeding, watering, egg collection, and manure removal systems significantly reduces labor requirements and operating expenses. This leads to higher operational efficiency and consistency.

- Improved Egg Quality and Collection: Eggs roll gently onto collection belts, minimizing breakages and contamination. This results in cleaner eggs with higher market value.

- Durability and Corrosion Resistance: The hot-dip galvanized coating provides exceptional resistance to the corrosive effects of ammonia and moisture prevalent in poultry environments, ensuring a long operational life and low maintenance requirements. This is a critical factor for long-term investment viability.

- Energy Saving (Indirect): Efficient space utilization and automated systems contribute to optimized heating, ventilation, and lighting requirements per bird, leading to indirect energy savings for the entire farm operation.

Industry Trends and Vendor Comparison for poultry cages for layers

The market for `poultry cages for layers` is continuously evolving, driven by technological advancements, welfare considerations, and economic pressures. Understanding these trends and comparing vendor offerings is crucial for informed investment decisions.

Current Industry Trends:

- Automation Integration: Increasing demand for fully automated systems covering feeding, watering, egg collection, and manure removal to reduce labor costs and improve consistency.

- Environmental Control Systems: Enhanced integration with climate control systems (ventilation, heating, cooling) to maintain optimal temperature and humidity for bird comfort and productivity.

- Smart Farming and IoT: Adoption of sensors and IoT devices for real-time monitoring of environmental parameters, feed consumption, water intake, and bird health, facilitating data-driven decision-making.

- Enriched Cage Systems: While battery cages offer efficiency, there is a growing trend, especially in Western markets, towards "enriched" or "colony" cages that provide more space, perches, and nesting areas to meet higher animal welfare standards.

- Sustainable Materials and Waste Management: Focus on durable, long-lasting materials and efficient manure handling systems that can convert waste into valuable byproducts like biogas or fertilizer.

Vendor Comparison: Key Differentiators

When selecting `modern poultry cage` solutions, several factors distinguish leading manufacturers. Our commitment to hot-dip galvanization and comprehensive support positions us favorably.

| Feature/Service | Yize Machine Co. (Our Offering) | Typical Competitor (Electro-Galvanized) | High-End Competitor (Enriched Cages) |

|---|---|---|---|

| Corrosion Protection | Hot-Dip Galvanized (>275g/m²) | Electro-Galvanized (10-30g/m²) | Hot-Dip Galvanized / PVC Coated |

| Service Life | 20-25 Years | 5-10 Years | 20+ Years |

| Initial Cost | Medium-High | Low | High |

| Automation Compatibility | High (Full system integration) | Limited (Manual/Semi-auto) | High (Full system integration) |

| Customization | Extensive (Layout, tiers, features) | Limited | Extensive |

| Installation Support | On-site supervision & training | Remote guidance only | On-site supervision & full installation |

| Warranty | Robust structural warranty (e.g., 5-10 years) | Limited (e.g., 1-2 years) | Comprehensive (e.g., 5-10 years) |

While initial investment in high-quality hot-dip galvanized `poultry cage mesh` systems might be higher, the total cost of ownership over two decades significantly favors superior materials due to reduced maintenance, longer lifespan, and consistent performance.

Customized Solutions and Application Case Studies for layer poultry cages for sale

Recognizing that no two poultry farms are identical, we offer extensive customization options to ensure our `layer poultry cages for sale` perfectly integrate with existing infrastructure and meet specific operational objectives. Our technical expertise allows for tailored designs that optimize space, improve workflow, and enhance productivity.

Customization Capabilities:

- Farm Layout Optimization: Our engineering team can develop custom cage layouts based on your specific poultry house dimensions, ceiling height, and desired bird capacity. This includes A-type or H-type configurations, multi-tier stacking, and aisle spacing.

- Integration with Existing Systems: We design cages that seamlessly integrate with your current feeding, watering, ventilation, and manure removal infrastructure, minimizing conversion costs and maximizing operational continuity.

- Material and Coating Variations: While hot-dip galvanization is standard, we can discuss alternative coatings or specific material thicknesses for extreme environmental conditions or specialized breeding requirements.

- Automation Level Flexibility: From fully automated feeding and egg collection to manual systems for smaller operations, we provide modular automation solutions that can be scaled according to budget and operational needs.

- Bird Welfare Enhancements: For markets with specific welfare regulations, we can adapt cage designs to include enriched features such as perches, scratching areas, and larger individual bird spaces.

Application Case Study: High-Density Layer Farm in Southeast Asia

Client Profile: A rapidly expanding commercial layer farm in Vietnam, aiming to increase its production capacity from 50,000 to 150,000 birds within a year, utilizing existing land resources efficiently.

Challenge: The client required a high-density solution that could withstand the region's humid climate, minimize labor costs, and provide superior environmental control within a newly constructed 150-meter long poultry house.

Solution: We designed and supplied 300 units of our 160-bird capacity H-type `poultry breeding cage` systems, configured in 4 tiers. Each system was hot-dip galvanized for maximum corrosion resistance. We integrated a fully automated feeding system with a spiral auger, automatic nipple drinkers, a conveyor belt manure removal system, and a central egg collection belt. Our team provided on-site supervision for installation and comprehensive training for local staff.

Results: Within six months of operation, the farm achieved its target capacity with a 98.5% daily egg collection rate and less than 1% egg breakage. The automated systems reduced labor requirements by 60%, allowing for significant operational savings. The robust hot-dip galvanized cages showed no signs of corrosion, even in the high-humidity environment. The client reported a remarkable improvement in feed conversion ratio and a noticeable reduction in disease incidence due to the superior hygiene maintained by the closed system.

Commitment to Trustworthiness: Support and Guarantees

Our dedication extends beyond delivering high-quality `poultry cages for layers`; we are committed to building lasting partnerships through transparent practices and unparalleled customer support.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a large-scale poultry breeding cage order?

- A1: For standard configurations, lead time typically ranges from 30 to 45 business days after deposit and design confirmation. Customized solutions may require an additional 15-20 days for engineering and fabrication. We maintain efficient production schedules to meet project timelines.

- Q2: What are the primary differences between A-type and H-type cage systems?

- A2: A-type cages are generally simpler, more economical, and suitable for smaller to medium-sized farms with manual or semi-automated systems. They typically have 3-4 tiers. H-type (vertical/battery) cages are fully enclosed, multi-tier (up to 8-10 tiers), designed for maximum density and full automation, ideal for large-scale, climate-controlled operations. Our `modern poultry cage` offerings include both, with H-type optimized for the highest bird counts per square meter.

- Q3: How do you ensure the hot-dip galvanization quality?

- A3: Our galvanization process strictly adheres to ISO 1461 and ASTM A123/A123M standards. We perform pre-treatment quality checks, ensure proper zinc bath temperature and immersion time, and conduct post-galvanization thickness measurements and adhesion tests on every batch to guarantee a minimum of 70-100 microns zinc coating for superior longevity and corrosion resistance.

Lead Time and Fulfillment:

Our streamlined production and logistics ensure efficient order fulfillment. We provide detailed project schedules, including manufacturing milestones, quality checks, packaging, and shipping estimates. For international clients, we manage all necessary export documentation and can arrange delivery via sea or land freight.

Warranty Commitments:

We stand by the quality of our products. All hot-dip galvanized `poultry cage mesh` structures come with a comprehensive 10-year warranty against manufacturing defects and significant corrosion under normal operating conditions. Automated components (feeders, egg collectors) typically carry a 1-year warranty, extendable based on specific service agreements.

Customer Support and After-Sales Service:

- Installation Assistance: We offer detailed installation manuals, video guides, and on-site supervision by our technical engineers for complex projects.

- Technical Training: Comprehensive training programs for your farm staff on operation, maintenance, and troubleshooting of the cage systems and associated automation.

- Spare Parts Availability: A readily available inventory of spare parts for all components ensures minimal downtime.

- 24/7 Technical Support: Our dedicated support team is available via phone and email to address any operational queries or technical issues promptly.

Yize Machine Co. is committed to being your reliable partner in modern poultry farming, delivering not just products, but complete, sustainable solutions for layer poultry production.

Authoritative References

- Food and Agriculture Organization of the United Nations (FAO). Good Practices in Planning and Management of Integrated Commercial Poultry Production in the Tropics. FAO Animal Production and Health Manual 18. Rome, 2017.

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization, Geneva.

- ASTM A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International, West Conshohocken, PA, 2017.

- The Poultry Site. Trends in global poultry production and consumption. Watt Global Media, 2023.

- United States Department of Agriculture (USDA) - National Agricultural Statistics Service (NASS). Poultry Production and Value. Annual Report, 2023.

-

Evisceration Table - Hygienic, Stainless Steel, Easy-Clean

NewsNov.17,2025

-

Chicken Plucker and Scalder | Fast, Stainless, Adjustable

NewsNov.17,2025

-

Silo Solutions: Durable, Automated, Batching-Ready Storage

NewsNov.17,2025

-

Automatic Drinking Line for Poultry | Precise & Durable

NewsNov.17,2025

-

Cutting Machine for Meat & Bone | High-Precision, Safe

NewsNov.17,2025

-

Chicken Feet Peeling Machine | Fast, Hygienic, High-Yield

NewsNov.10,2025

Sep . 08, 2025 16:38 Back to list

Modern Poultry Breeding Cage | High-Yield Layer Cages For Sale

Strategic Advancements in Modern Poultry Breeding Systems

The global demand for poultry products continues its upward trajectory, necessitating sophisticated and efficient farming solutions. At the forefront of this evolution are advanced poultry breeding cage systems. These systems are meticulously engineered to optimize bird welfare, enhance productivity, and streamline operational management for large-scale agricultural enterprises. Our focus today is on understanding the technical intricacies, market dynamics, and operational advantages of these indispensable farming components, particularly the high-capacity 96, 120, 128, and 160 birds layer poultry battery chicken cages designed for modern layer operations.

The industry is rapidly transitioning from traditional floor systems to sophisticated battery cage setups, driven by factors such as space utilization, disease control, and automation capabilities. This shift has profound implications for profitability and sustainability in the poultry sector.

Manufacturing Precision: The Process Flow of Modern poultry breeding cage Systems

The production of high-quality poultry breeding cage systems involves a series of advanced manufacturing processes, ensuring durability, hygiene, and optimal functionality. Each step is rigorously controlled to meet stringent industry standards and client specifications.

Materials and Design Engineering:

Our cages are primarily constructed from high-tensile, low-carbon steel wire. This material is selected for its strength, ductility, and suitability for galvanization. Initial designs undergo sophisticated CAD software modeling, allowing for precise structural analysis, load bearing calculations, and optimization for ventilation, feeding access, and waste removal. Ergonomic considerations for bird welfare, such as appropriate cage floor angles and spacing, are integral to this phase.

Fabrication Process:

- Wire Drawing and Straightening: Raw steel wire coils are drawn to the required gauge and precisely straightened to eliminate deformations.

- Automated Mesh Welding: CNC-controlled welding machines are employed to create the uniform cage mesh panels. This process ensures consistent grid spacing, superior weld strength, and minimal material waste. Resistance welding is preferred for its clean, strong joints.

- Cutting and Bending: The welded mesh panels are cut to exact dimensions using automated shears. Subsequent bending operations, guided by hydraulic press brakes, form the various sections of the cage structure, including floor panels, side walls, and roof segments, ensuring accurate geometry for seamless assembly.

- Hot-Dip Galvanization: This is a critical process for enhancing corrosion resistance and extending service life. After fabrication, components are meticulously cleaned (degreasing, pickling) and then immersed in a bath of molten zinc. The resulting metallurgical bond provides a robust, sacrificial coating that protects the steel from environmental degradation, particularly in the humid and ammonia-rich environment of poultry houses. A typical galvanization layer achieves a thickness of 70-100 microns, ensuring decades of service.

- Accessory Manufacturing: Complementary components such as feeding troughs (often from PVC or galvanized steel), watering nipples (stainless steel with plastic housing), and manure belts (PP material) are produced concurrently, adhering to strict hygiene and durability standards.

Quality Control and Testing Standards:

Our manufacturing process adheres strictly to international quality management systems, notably ISO 9001:2015. Each batch undergoes rigorous testing:

- Material Composition Analysis: Spectroscopic analysis to verify steel alloy composition.

- Weld Integrity Testing: Non-destructive tests (e.g., visual inspection, tensile strength tests on samples) ensure robust connections.

- Galvanization Thickness Measurement: Magnetic induction gauges confirm the zinc coating thickness meets or exceeds specified ASTM A123/A123M or ISO 1461 standards.

- Dimensional Accuracy: Precision calipers and laser measurement systems verify all component dimensions against engineering drawings.

- Functional Load Testing: Sample cages are subjected to simulated operational loads to ensure structural stability and longevity.

The typical service life of our hot-dip galvanized poultry breeding cage systems exceeds 20 years under proper maintenance, outperforming electro-galvanized alternatives by a significant margin due to superior corrosion resistance.

Technical Specifications: Layer Poultry Battery Chicken Cages

Our leading product line, the 96, 120, 128, and 160 Birds Layer Poultry Battery Chicken Cages, exemplifies advanced design and robust construction. These systems are specifically engineered to maximize bird density while ensuring optimal welfare and productivity.

Product Specification Table:

| Parameter | Detail |

|---|---|

| Cage Type | A-Type Battery Cage System (Multi-tier) |

| Capacity Options (Birds) | 96, 120, 128, 160 (per unit) |

| Dimensions (L x W x H per unit) | Typically 1.8m - 2.2m x 0.5m x 1.8m (variable by capacity) |

| Cage Cells per Unit | 24, 30, 32, 40 (cells, 4 birds/cell average) |

| Material | High-quality Q235 steel wire, hot-dip galvanized |

| Wire Diameter | Main frame: 3.2-3.8mm; Bottom mesh: 2.2-2.5mm |

| Corrosion Protection | Hot-dip galvanization (zinc coating > 275 g/m², typically 70-100 microns) |

| Feeding System | Manual or Automated (chain, trough, or spiral auger) |

| Watering System | Automatic nipple drinkers with pressure regulators |

| Manure Removal System | Manure scraper system or conveyor belt system (integrated or separate) |

| Egg Collection | Automatic rolling egg collection system or manual |

| Service Life | 20-25 years with proper maintenance |

Application Scenarios and Technical Advantages

Our poultry breeding cage systems are designed for high-density, efficient layer farming operations, finding extensive application across various scales of poultry enterprises.

Target Industries and Application Scenarios:

- Commercial Layer Farms: Ideal for large-scale production of table eggs, maximizing bird density per square meter of housing.

- Breeder Farms: Though designed for layers, adaptations can be made for specific breeder applications requiring controlled environments and optimized reproductive cycles.

- Agricultural Cooperatives: Enables efficient resource sharing and centralized management for multiple small to medium-sized farmers.

- Poultry Research Facilities: Provides standardized and controlled environments for scientific studies on nutrition, genetics, and disease management.

Technical Advantages in Operation:

- Optimized Space Utilization: Multi-tier design allows for significantly higher bird density, reducing land requirements and construction costs for poultry houses. An H-type cage system can house up to 3 times more birds in the same footprint compared to floor rearing.

- Enhanced Biosecurity and Disease Control: Birds are isolated from their feces, drastically reducing the risk of parasitic infections (e.g., coccidiosis) and bacterial diseases. Improved air circulation in battery cages also contributes to better respiratory health.

- Superior Feed Conversion Ratio: Controlled feeding systems minimize feed wastage, and reduced physical activity of caged birds contributes to better feed conversion, leading to lower operational costs.

- Automated Management Potential: Compatibility with automated feeding, watering, egg collection, and manure removal systems significantly reduces labor requirements and operating expenses. This leads to higher operational efficiency and consistency.

- Improved Egg Quality and Collection: Eggs roll gently onto collection belts, minimizing breakages and contamination. This results in cleaner eggs with higher market value.

- Durability and Corrosion Resistance: The hot-dip galvanized coating provides exceptional resistance to the corrosive effects of ammonia and moisture prevalent in poultry environments, ensuring a long operational life and low maintenance requirements. This is a critical factor for long-term investment viability.

- Energy Saving (Indirect): Efficient space utilization and automated systems contribute to optimized heating, ventilation, and lighting requirements per bird, leading to indirect energy savings for the entire farm operation.

Industry Trends and Vendor Comparison for poultry cages for layers

The market for `poultry cages for layers` is continuously evolving, driven by technological advancements, welfare considerations, and economic pressures. Understanding these trends and comparing vendor offerings is crucial for informed investment decisions.

Current Industry Trends:

- Automation Integration: Increasing demand for fully automated systems covering feeding, watering, egg collection, and manure removal to reduce labor costs and improve consistency.

- Environmental Control Systems: Enhanced integration with climate control systems (ventilation, heating, cooling) to maintain optimal temperature and humidity for bird comfort and productivity.

- Smart Farming and IoT: Adoption of sensors and IoT devices for real-time monitoring of environmental parameters, feed consumption, water intake, and bird health, facilitating data-driven decision-making.

- Enriched Cage Systems: While battery cages offer efficiency, there is a growing trend, especially in Western markets, towards "enriched" or "colony" cages that provide more space, perches, and nesting areas to meet higher animal welfare standards.

- Sustainable Materials and Waste Management: Focus on durable, long-lasting materials and efficient manure handling systems that can convert waste into valuable byproducts like biogas or fertilizer.

Vendor Comparison: Key Differentiators

When selecting `modern poultry cage` solutions, several factors distinguish leading manufacturers. Our commitment to hot-dip galvanization and comprehensive support positions us favorably.

| Feature/Service | Yize Machine Co. (Our Offering) | Typical Competitor (Electro-Galvanized) | High-End Competitor (Enriched Cages) |

|---|---|---|---|

| Corrosion Protection | Hot-Dip Galvanized (>275g/m²) | Electro-Galvanized (10-30g/m²) | Hot-Dip Galvanized / PVC Coated |

| Service Life | 20-25 Years | 5-10 Years | 20+ Years |

| Initial Cost | Medium-High | Low | High |

| Automation Compatibility | High (Full system integration) | Limited (Manual/Semi-auto) | High (Full system integration) |

| Customization | Extensive (Layout, tiers, features) | Limited | Extensive |

| Installation Support | On-site supervision & training | Remote guidance only | On-site supervision & full installation |

| Warranty | Robust structural warranty (e.g., 5-10 years) | Limited (e.g., 1-2 years) | Comprehensive (e.g., 5-10 years) |

While initial investment in high-quality hot-dip galvanized `poultry cage mesh` systems might be higher, the total cost of ownership over two decades significantly favors superior materials due to reduced maintenance, longer lifespan, and consistent performance.

Customized Solutions and Application Case Studies for layer poultry cages for sale

Recognizing that no two poultry farms are identical, we offer extensive customization options to ensure our `layer poultry cages for sale` perfectly integrate with existing infrastructure and meet specific operational objectives. Our technical expertise allows for tailored designs that optimize space, improve workflow, and enhance productivity.

Customization Capabilities:

- Farm Layout Optimization: Our engineering team can develop custom cage layouts based on your specific poultry house dimensions, ceiling height, and desired bird capacity. This includes A-type or H-type configurations, multi-tier stacking, and aisle spacing.

- Integration with Existing Systems: We design cages that seamlessly integrate with your current feeding, watering, ventilation, and manure removal infrastructure, minimizing conversion costs and maximizing operational continuity.

- Material and Coating Variations: While hot-dip galvanization is standard, we can discuss alternative coatings or specific material thicknesses for extreme environmental conditions or specialized breeding requirements.

- Automation Level Flexibility: From fully automated feeding and egg collection to manual systems for smaller operations, we provide modular automation solutions that can be scaled according to budget and operational needs.

- Bird Welfare Enhancements: For markets with specific welfare regulations, we can adapt cage designs to include enriched features such as perches, scratching areas, and larger individual bird spaces.

Application Case Study: High-Density Layer Farm in Southeast Asia

Client Profile: A rapidly expanding commercial layer farm in Vietnam, aiming to increase its production capacity from 50,000 to 150,000 birds within a year, utilizing existing land resources efficiently.

Challenge: The client required a high-density solution that could withstand the region's humid climate, minimize labor costs, and provide superior environmental control within a newly constructed 150-meter long poultry house.

Solution: We designed and supplied 300 units of our 160-bird capacity H-type `poultry breeding cage` systems, configured in 4 tiers. Each system was hot-dip galvanized for maximum corrosion resistance. We integrated a fully automated feeding system with a spiral auger, automatic nipple drinkers, a conveyor belt manure removal system, and a central egg collection belt. Our team provided on-site supervision for installation and comprehensive training for local staff.

Results: Within six months of operation, the farm achieved its target capacity with a 98.5% daily egg collection rate and less than 1% egg breakage. The automated systems reduced labor requirements by 60%, allowing for significant operational savings. The robust hot-dip galvanized cages showed no signs of corrosion, even in the high-humidity environment. The client reported a remarkable improvement in feed conversion ratio and a noticeable reduction in disease incidence due to the superior hygiene maintained by the closed system.

Commitment to Trustworthiness: Support and Guarantees

Our dedication extends beyond delivering high-quality `poultry cages for layers`; we are committed to building lasting partnerships through transparent practices and unparalleled customer support.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a large-scale poultry breeding cage order?

- A1: For standard configurations, lead time typically ranges from 30 to 45 business days after deposit and design confirmation. Customized solutions may require an additional 15-20 days for engineering and fabrication. We maintain efficient production schedules to meet project timelines.

- Q2: What are the primary differences between A-type and H-type cage systems?

- A2: A-type cages are generally simpler, more economical, and suitable for smaller to medium-sized farms with manual or semi-automated systems. They typically have 3-4 tiers. H-type (vertical/battery) cages are fully enclosed, multi-tier (up to 8-10 tiers), designed for maximum density and full automation, ideal for large-scale, climate-controlled operations. Our `modern poultry cage` offerings include both, with H-type optimized for the highest bird counts per square meter.

- Q3: How do you ensure the hot-dip galvanization quality?

- A3: Our galvanization process strictly adheres to ISO 1461 and ASTM A123/A123M standards. We perform pre-treatment quality checks, ensure proper zinc bath temperature and immersion time, and conduct post-galvanization thickness measurements and adhesion tests on every batch to guarantee a minimum of 70-100 microns zinc coating for superior longevity and corrosion resistance.

Lead Time and Fulfillment:

Our streamlined production and logistics ensure efficient order fulfillment. We provide detailed project schedules, including manufacturing milestones, quality checks, packaging, and shipping estimates. For international clients, we manage all necessary export documentation and can arrange delivery via sea or land freight.

Warranty Commitments:

We stand by the quality of our products. All hot-dip galvanized `poultry cage mesh` structures come with a comprehensive 10-year warranty against manufacturing defects and significant corrosion under normal operating conditions. Automated components (feeders, egg collectors) typically carry a 1-year warranty, extendable based on specific service agreements.

Customer Support and After-Sales Service:

- Installation Assistance: We offer detailed installation manuals, video guides, and on-site supervision by our technical engineers for complex projects.

- Technical Training: Comprehensive training programs for your farm staff on operation, maintenance, and troubleshooting of the cage systems and associated automation.

- Spare Parts Availability: A readily available inventory of spare parts for all components ensures minimal downtime.

- 24/7 Technical Support: Our dedicated support team is available via phone and email to address any operational queries or technical issues promptly.

Yize Machine Co. is committed to being your reliable partner in modern poultry farming, delivering not just products, but complete, sustainable solutions for layer poultry production.

Authoritative References

- Food and Agriculture Organization of the United Nations (FAO). Good Practices in Planning and Management of Integrated Commercial Poultry Production in the Tropics. FAO Animal Production and Health Manual 18. Rome, 2017.

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization, Geneva.

- ASTM A123/A123M-17, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International, West Conshohocken, PA, 2017.

- The Poultry Site. Trends in global poultry production and consumption. Watt Global Media, 2023.

- United States Department of Agriculture (USDA) - National Agricultural Statistics Service (NASS). Poultry Production and Value. Annual Report, 2023.