High-Precision Automatic Egg Grading Machine for Sale

Aug . 26, 2025 01:40 Back to list

High-Precision Automatic Egg Grading Machine for Sale

Elevating Efficiency in Egg Processing: The Industrial Automatic Egg Grading Machine

In the modern poultry industry, precision, hygiene, and efficiency are paramount. The demand for consistent quality and accurate sizing of eggs has driven significant advancements in processing technology. For businesses seeking a reliable egg grading machine for sale, understanding the intricate details of these sophisticated systems is crucial. This comprehensive guide delves into the technical aspects, operational advantages, and strategic considerations for acquiring an industrial automatic egg grading machine.

Modern consumers and retailers expect eggs to be uniformly graded by weight, free from cracks, and handled with the utmost care to maintain their internal quality. Manual grading is labor-intensive, prone to human error, and simply cannot meet the throughput demands of large-scale operations. This is where the automatic egg grading machine becomes indispensable, transforming a labor-intensive chore into a streamlined, high-precision operation. Industry trends indicate a consistent shift towards automation, driven by rising labor costs, stricter hygiene regulations, and the need for greater operational scalability and data-driven insights. As such, investing in an advanced egg grading machine is no longer just an option but a strategic imperative for competitive advantage and sustainable growth.

Understanding the Industrial Automatic Egg Grading Machine

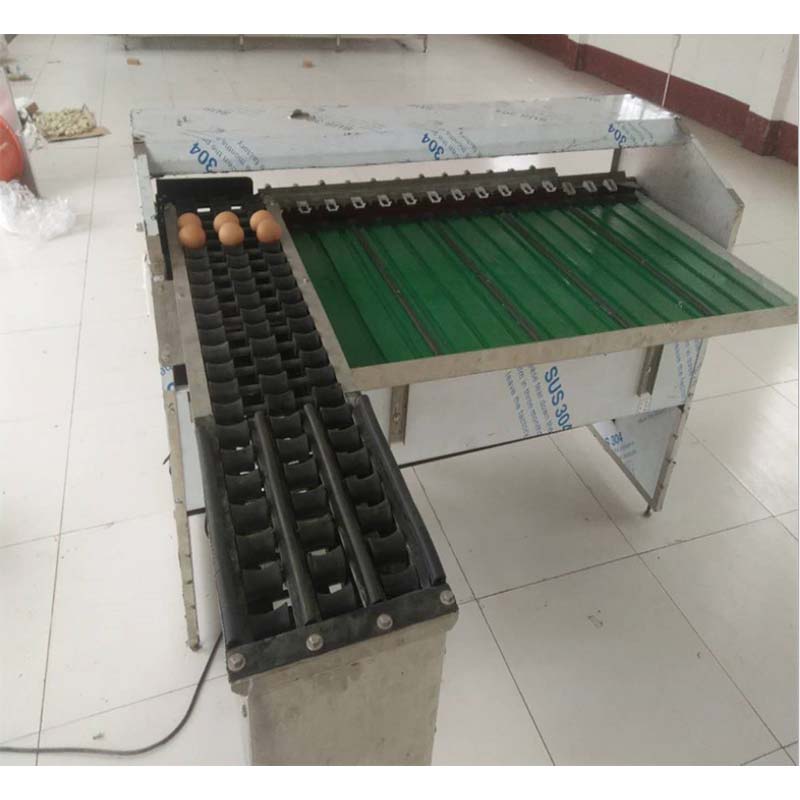

An Industrial Automatic Egg Grading Machine, also known as an Egg Sorter or Egg Sorting Machine, is a specialized piece of equipment designed to accurately weigh, sort, and often package eggs based on predefined criteria, primarily weight. These machines are engineered for high-volume processing environments, ensuring that eggs meet market standards and consumer expectations.

Key components typically include:

- • Egg Input System: Conveyors or vacuum lifters that gently transfer eggs from trays or collection belts onto the grading line.

- • Candling Unit: An optional but critical module that uses light to detect cracks, blood spots, or other internal defects, removing substandard eggs.

- • Weighing System: High-precision electronic scales (load cells) that accurately measure the weight of each individual egg as it passes.

- • Sorting Mechanism: Robotic arms, conveyor drops, or other mechanical means that direct eggs into designated collection lanes based on their weight grade.

- • Output/Packing Section: Lanes leading to manual or automatic packing systems, where graded eggs are placed into cartons or trays.

- • Control System: A Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) for operation, monitoring, and data logging.

The Advanced Manufacturing Process of an Automatic Egg Grading Machine

The creation of a high-performance automatic egg grading machine involves a sophisticated manufacturing process, integrating robust materials with precision engineering to ensure longevity, hygiene, and operational excellence.

Materials and Components:

The primary materials selected for an industrial egg grading machine for sale are chosen for their durability, food-grade compliance, and resistance to corrosion and wear.

- • Stainless Steel (e.g., SUS304, SUS316): Widely used for contact parts, frames, and enclosures due to its excellent corrosion resistance, ease of cleaning, and hygienic properties, meeting stringent food safety standards like FDA and HACCP.

- • Food-Grade Plastics/Polymers: Utilized for egg handling cups, conveyor belts, and other delicate contact surfaces to minimize impact and prevent shell damage. Materials like polyethylene (PE) or polypropylene (PP) are common.

- • Precision Electronics: High-accuracy load cells, sensors, PLCs, and servo motors from reputable manufacturers (e.g., Siemens, Schneider, Rockwell) ensure reliable and precise operation.

Manufacturing Processes:

- Material Preparation & Cutting: Stainless steel sheets and profiles are cut using laser cutting or CNC plasma cutting for high precision and minimal material waste.

- Forming & Bending: CNC bending machines shape components, ensuring structural integrity and precise dimensions.

- Welding & Fabrication: Skilled technicians perform TIG or MIG welding to assemble frames and enclosures. All welds are meticulously finished to prevent bacterial traps, critical for food processing equipment.

- Precision Machining: Critical components like shafts, gears, and intricate sensor housings are manufactured using CNC machining to achieve tight tolerances and smooth finishes.

- Surface Treatment: Polishing and passivation of stainless steel surfaces enhance corrosion resistance and ease of cleaning.

- Assembly: Mechanical, electrical, and pneumatic components are integrated by specialized teams. Wiring is routed meticulously to comply with electrical safety standards (e.g., UL, CE).

- Software Integration & Testing: PLC programming and HMI development are crucial. Each machine undergoes rigorous dry run and wet run testing with dummy eggs or actual eggs to verify grading accuracy, speed, and gentle handling.

Quality Control & Testing Standards:

Manufacturers adhere to strict quality control protocols throughout the entire production cycle, ensuring compliance with international standards.

- • ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality.

- • CE Marking: Compliance with European health, safety, and environmental protection standards.

- • FDA/HACCP Guidelines: Adherence to food safety regulations is paramount for all food-contact materials and design principles.

- • Accuracy Calibration: Regular calibration of weighing systems using certified weights to ensure grading precision.

- • Durability Testing: Components undergo stress tests to predict service life, often exceeding 10-15 years with proper maintenance.

Technical Specifications and Performance Parameters

When evaluating an egg grading machine for sale, prospective buyers must scrutinize key technical specifications that dictate performance and suitability for their operations. These parameters directly influence throughput, accuracy, and overall operational cost-efficiency.

| Parameter | Typical Range / Specification | Significance for Operators |

|---|---|---|

| Capacity (eggs/hour) | 5,000 - 30,000+ | Determines throughput and scalability for production demands. |

| Grading Accuracy | ±0.5g - ±1g | Ensures precise weight classification, minimizing giveaway or underselling. |

| Number of Grades/Lanes | 3 - 9+ grades | Flexibility to sort into various market categories (e.g., Small, Medium, Large, XL). |

| Power Consumption | 1.5 kW - 5 kW | Impacts operational costs; energy-efficient models reduce overhead. |

| Egg Damage Rate | Typically | Crucial for minimizing product loss and maximizing yield. |

| Material Construction | Food-grade SUS304/SUS316 stainless steel | Ensures hygiene, durability, and compliance with food safety regulations. |

| Operating Temperature | 0°C - 40°C | Indicates suitability for various climate-controlled environments. |

Technical Advantages of Modern Automatic Egg Graders

The technological leap in modern egg grading machine for sale offerings provides several compelling advantages for businesses in the egg industry:

- • Unparalleled Precision and Consistency: Advanced load cell technology and digital control systems ensure each egg is weighed with extreme accuracy (e.g., ±0.5g), significantly reducing weight variance within grades and minimizing product "giveaway." This directly translates to improved profitability.

- • High Throughput and Efficiency: Capable of processing tens of thousands of eggs per hour, these machines dramatically increase operational efficiency and output, far surpassing manual methods. This leads to substantial labor cost reductions and faster market readiness.

- • Gentle Egg Handling: Engineered with soft-touch components, advanced conveyor designs, and optimized drop mechanisms, modern egg graders drastically reduce the incidence of cracks and breakages, preserving product integrity and reducing waste.

- • Superior Hygiene and Sanitation: Constructed from food-grade stainless steel (e.g., SUS304) and designed for easy disassembly and washdown, these machines meet rigorous hygiene standards, preventing bacterial contamination and ensuring food safety.

- • Data Analytics and Traceability: Integrated PLC/HMI systems allow for real-time monitoring of performance, production data logging, and batch traceability. This data is invaluable for quality control, process optimization, and regulatory compliance.

- • Reduced Labor Dependency: By automating the grading process, businesses can reallocate personnel to other critical tasks, addressing labor shortages and improving overall workforce productivity.

Application Scenarios: Where These Machines Excel

The versatility and efficiency of industrial automatic egg grading machine solutions make them indispensable across various segments of the egg industry.

- • Large-Scale Commercial Poultry Farms: For farms with tens of thousands or even millions of laying hens, an integrated grading and packing system is essential to process the daily egg output efficiently and prepare it for distribution.

- • Egg Packing Houses: These facilities receive eggs from multiple farms, perform washing, candling, grading, and packing before distribution to supermarkets, restaurants, and other food service providers. An egg grading machine is the core of their operation.

- • Food Processing Plants: Industries requiring a consistent supply of graded eggs for further processing (e.g., bakeries, mayonnaise manufacturers, liquid egg producers) rely on these machines to ensure uniform ingredient quality.

- • Egg Distribution Centers: Central hubs that manage the sorting and logistics of eggs from various sources benefit from high-capacity graders to streamline their supply chain operations.

Vendor Comparison: Choosing the Right Egg Grading Machine Manufacturer

Selecting the right `egg grading machine for sale` involves more than just looking at technical specs; it requires a thorough evaluation of potential egg grading machine manufacturers. Factors like reputation, after-sales support, customization capabilities, and technological innovation are critical.

| Feature/Criterion | Tier 1 Manufacturer (e.g., Yize Machine) | Mid-Tier Manufacturer |

|---|---|---|

| Product Quality & Durability | Premium SUS304/316, precision CNC, robust construction, 10-15+ year service life. | Often SUS201, adequate construction, 5-8 year service life. |

| Grading Accuracy | Superior (±0.5g), advanced load cells, minimal variation. | Good (±1g), standard load cells, acceptable variation. |

| Automation & Control | Full PLC/HMI, advanced software, remote diagnostics, data analytics. | Basic PLC, local HMI, limited data logging. |

| Customization Options | Extensive (capacity, sorting lanes, washing, candling, packing integration). | Limited modifications, standard configurations. |

| After-Sales Support | Comprehensive global network, 24/7 technical support, on-site service, spare parts availability. | Regional support, limited hours, slower spare parts. |

| Certifications | ISO, CE, FDA/HACCP compliance. | Often only CE, may lack specific food safety accreditations. |

| Price Point (Relative) | Higher initial investment, lower TCO due to longevity and efficiency. | Lower initial investment, potentially higher long-term costs. |

For discerning buyers, the long-term total cost of ownership (TCO) often favors manufacturers offering higher quality, better support, and superior efficiency, even with a higher initial price. These Tier 1 manufacturers, such as Yize Machine, emphasize engineering excellence and robust after-sales infrastructure, ensuring that your investment in an egg grading machine yields maximum returns over its extended operational lifespan.

Customized Solutions for Diverse Operational Needs

Recognizing that no two egg processing operations are identical, leading egg grading machine manufacturers offer extensive customization options. This flexibility ensures that the machine perfectly integrates into existing facility layouts and meets specific production requirements.

Customization can include:

- • Capacity Adjustment: Scaling the machine to handle varying egg volumes, from medium-scale operations (5,000 eggs/hour) to mega-farms (70,000+ eggs/hour).

- • Number of Grading Lanes: Configuring the machine with specific numbers of output lanes to match the required egg grades for different markets (e.g., Small, Medium, Large, Extra Large, Jumbo).

- • Integrated Modules: Adding functionalities such as automatic egg washing, online candling (for crack and defect detection), UV sanitization, automatic date printing, and various packing solutions (e.g., carton loaders, stackers).

- • Layout and Footprint: Adapting the machine's physical dimensions and configuration (e.g., straight-line, L-shaped) to fit existing processing plant layouts, optimizing space utilization.

- • Software Integration: Customizing the control software to interface with existing Enterprise Resource Planning (ERP) systems or for specialized reporting and data analysis.

Real-World Application Case Studies

The tangible benefits of an industrial automatic egg grading machine are best illustrated through successful deployments.

Case Study 1: Large-Scale Poultry Farm in North America

A leading North American poultry producer, managing over 2 million laying hens, faced challenges with inconsistent grading accuracy and high labor costs using older semi-automatic systems. They invested in a Yize Machine 30,000 eggs/hour integrated grading and packing line.

- • Outcome: Achieved a 99.8% grading accuracy, reducing underweight/overweight packaging errors by 70%. Labor required for grading and packing was reduced by 60%, reallocating staff to value-added tasks. The gentle handling mechanism decreased egg breakage rates from 0.4% to less than 0.05%, resulting in significant cost savings from reduced waste.

Case Study 2: European Egg Packing and Distribution Center

A major European egg distribution center needed to upgrade its facilities to meet new EU traceability regulations and increase processing speed. They opted for a customized egg grading machine for sale from Yize Machine, featuring advanced candling, UV disinfection, and integrated online printing.

- • Outcome: The system allowed for real-time defect detection, improving overall egg quality entering the market. Enhanced data logging features provided full batch traceability, simplifying audits and ensuring compliance. Operational capacity increased by 40%, allowing the center to expand its market reach.

Ensuring Quality and Reliability (Google EEAT Compliance)

For B2B decision-makers, assurance of quality, expertise, and trustworthiness is paramount. Reputable egg grading machine manufacturers distinguish themselves through verifiable credentials and a commitment to excellence.

Authoritativeness:

- • Certifications: Machines are typically CE certified, ISO 9001 quality management certified, and designed in accordance with HACCP principles for food safety.

- • Years of Service: Established manufacturers often boast decades of experience in the poultry equipment sector, with a proven track record of successful installations globally.

- • Partner Clients: Collaborations with major international egg producers and distributors underline industry trust and product performance.

- • Test Data: Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) provide documented evidence of performance against agreed-upon specifications, including accuracy, capacity, and damage rates.

Trustworthiness and Support:

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for an automatic egg grading machine?

A: Lead times vary depending on customization and capacity. Standard models typically have a lead time of 6-10 weeks, while highly customized systems may require 12-16 weeks. We provide a detailed project timeline upon order confirmation.

Q: What kind of warranty is offered?

A: We offer a standard 12 to 24-month warranty on mechanical and electrical components, covering manufacturing defects. Extended warranty options and service contracts are also available.

Q: How is after-sales support provided?

A: Our comprehensive after-sales support includes remote technical assistance, on-site installation and commissioning services, operator training, and a readily available supply of spare parts. We maintain a global network of service engineers to ensure prompt response times.

Q: Can the machine handle different sizes or types of eggs?

A: Yes, our automatic egg grading machines are designed with adjustable settings to accommodate various egg sizes (e.g., chicken, duck, quail eggs, depending on the model) and grading specifications. The weighing parameters are fully programmable via the HMI.

Conclusion: A Strategic Investment for the Future

The industrial automatic egg grading machine is a cornerstone technology for any modern egg processing operation aiming for efficiency, precision, and profitability. From enhancing product quality and reducing labor costs to ensuring compliance with stringent food safety standards, the benefits are clear. As global demand for high-quality, consistently graded eggs continues to grow, investing in an advanced egg grading machine for sale from a reputable manufacturer like Yize Machine is a strategic decision that promises significant returns and a robust competitive edge in the dynamic poultry industry. By leveraging cutting-edge technology and comprehensive support, businesses can optimize their operations, meet market demands, and secure their position for future growth.

References:

- Food and Agriculture Organization of the United Nations (FAO) - The Poultry Industry: Structure and Trends. (Access via: fao.org)

- International Organization for Standardization (ISO) - Quality Management System Standards. (Access via: iso.org)

- U.S. Food and Drug Administration (FDA) - Food Safety Modernization Act (FSMA) for Egg Production. (Access via: fda.gov)

- World Poultry Science Journal - Automation in Egg Processing: A Review. (Access via: wpsa.com)

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025