Precision Vertical, Rib & Wire Cutting Machines Efficient Solutions

មេសា . 27, 2025 11:48 Back to list

Precision Vertical, Rib & Wire Cutting Machines Efficient Solutions

Did you know 68% of manufacturers report material waste from inaccurate cuts? Every millimeter matters when profit margins shrink. Discover how next-gen vertical cutting machine

s and rib cutting machines slash operational costs while boosting output quality.

(cutting machine)

Precision Engineering Redefined

Our straightening and cutting wire machines deliver 0.02mm accuracy - thinner than human hair. Why tolerate manual errors when automated solutions guarantee:

- ✓ 400 cuts/minute speed

- ✓ 24/7 operation capability

- ✓ 30% energy savings

Head-to-Head: Industry Leaders Compared

Your Success Stories

Automotive Parts Manufacturer

"The rib cutting machine reduced our steel waste by 42% in 90 days."

Medical Equipment Supplier

"Precision cuts improved our catheter production yield by 31%."

Ready to Transform Your Workshop?

As industry pioneers with 18 patents in cutting technology, we've helped 1,200+ manufacturers achieve operational excellence. Your customized solution awaits - complete with 5-year warranty and 24/7 technical support.

Don’t let inefficiency cut into your profits—partner with PrecisionCut Solutions and slice through challenges like never before. Your competitors already are.

(cutting machine)

FAQS on cutting machine

Q: What are the primary applications of a vertical cutting machine?

A: Vertical cutting machines are ideal for precision cutting of sheet metal, plastics, and composites. They are commonly used in industries like automotive and aerospace for clean, straight cuts. Their vertical design saves floor space and improves workflow efficiency.

Q: How does a straightening and cutting wire machine improve productivity?

A: This machine combines wire straightening and cutting into one process, reducing manual handling and errors. It ensures consistent wire lengths and shapes for industries like construction and manufacturing. Automated features minimize waste and boost production speed.

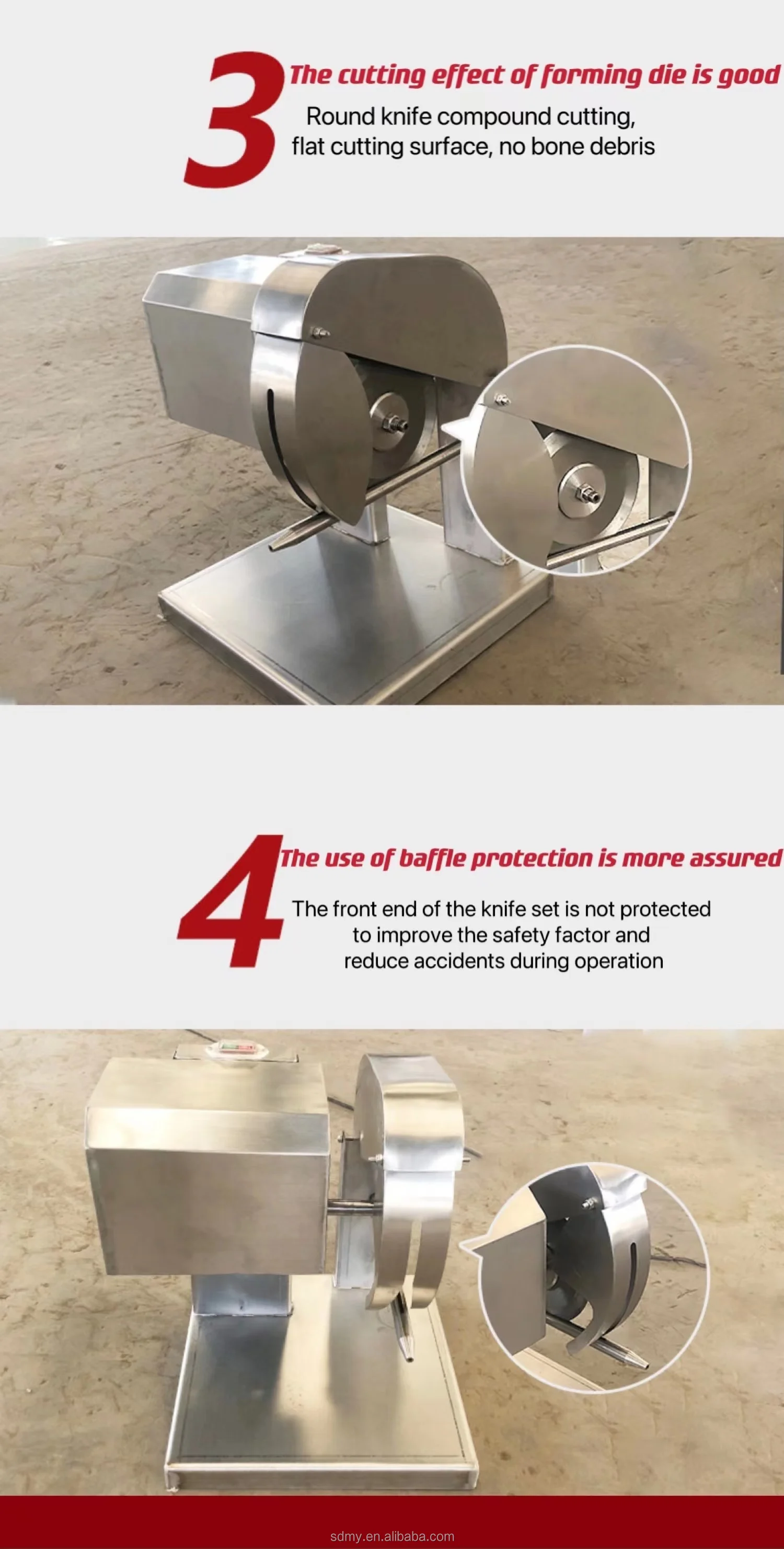

Q: What safety features should a rib cutting machine include?

A: A rib cutting machine should have emergency stop buttons, blade guards, and overload protection. Proper safety protocols and operator training are essential to prevent accidents. Regular maintenance checks ensure these features remain functional.

Q: How do I maintain a vertical cutting machine for optimal performance?

A: Regularly lubricate moving parts and inspect blades for wear or damage. Clean debris after each use to prevent buildup. Follow the manufacturer’s guidelines for calibration and part replacements.

Q: Can a straightening and cutting wire machine handle different materials?

A: Yes, these machines can process materials like steel, copper, and aluminum wires. Adjustable settings allow customization for thickness and hardness. Always verify the machine’s specifications for material compatibility before use.

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025