Metal Rabbit Cage: Durable, Safe, Easy-Clean, 4-Hole Ready

Oct . 16, 2025 11:45 Back to list

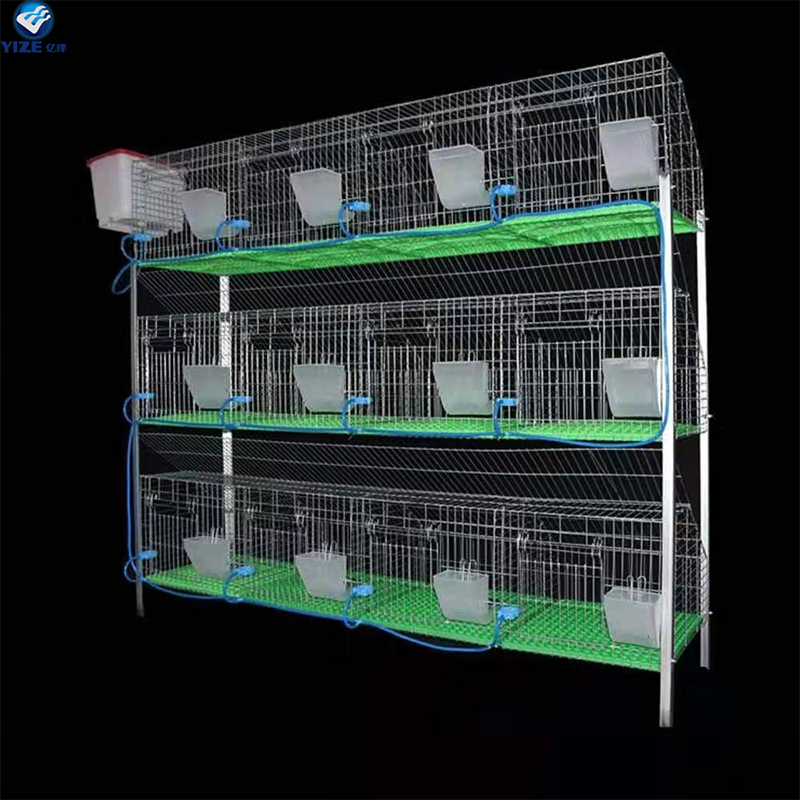

Metal Rabbit Cage: Durable, Safe, Easy-Clean, 4-Hole Ready

What to Look for in a Metal Rabbit Cage: Insider Notes, Specs, and Real-World Results

If you’re sourcing a metal rabbit cage for a farm rollout or a scaled backyard setup, here’s the short version: structure, surface treatment, and after-sales matter more than glossy brochures. I’ve walked enough barns to know a good cage saves labor, feed, and headaches. The model below—Wholesale Rabbit Hutch Designs/Rabbit Battery Wire Cages—comes out of Anping County (Hebei, China), a well-known mesh hub. That pedigree shows up in the welds and the zinc.

Market trends you’ll actually notice on-site

- Shift to modular “battery” stacks that maximize cubic space without choking airflow.

- Hot-dip galvanizing or heavy zinc-aluminum coatings replacing light electro-galv (less rust; fewer replacements).

- Welfare-driven tweaks: smoother step nets, rounded edges, deeper fecal trays. Surprisingly, these reduce paw injuries and lower vet calls, according to several growers I spoke with this spring.

Core build and technical spec (buyer’s cheat sheet)

| Model | Wholesale Rabbit Hutch Designs / Rabbit Battery Wire Cages |

| Material | Low-carbon steel wire (Q235) ≈ 3.0–4.0 mm frame; 2.0–2.8 mm mesh |

| Mesh Aperture | Step net: 12×50 mm; sides/top: 25×50 mm (options around 20–25×50 mm) |

| Coating | Hot-dip galvanizing (ISO 1461) ≈ 50–90 µm; or heavy electro-galv for economy builds |

| Modules | Cage door, step net/pedal, side net, rear window, top net, fecal plate, feeders, drinkers |

| Typical Stack | 2–4 tiers; aisle-friendly footprint; custom footprints available |

| Service Life | ≈ 6–10 years in normal indoor barns; around 3–5 near coastal humidity (real-world use may vary) |

Manufacturing flow and QC (the boring bits that save money later)

Materials are straightened Q235 wire, resistance spot-welded on jigs for consistent aperture. After fabrication, parts go through pickling, flux, then hot-dip galvanizing; drainage holes are positioned so zinc doesn’t pool at corners (helps paw safety). QC includes weld shear tests, coating thickness checks (mag gauge), and burr removal.

Typical tests: ISO 1461 zinc spec; ASTM A641 for galvanized wire; ISO 9227 neutral salt spray (sample lots: 240–480 h, red rust ≤5% on flats); ISO 2409 adhesion if powder topcoat is requested. Some buyers ask for SGS reports; that’s common and, frankly, useful when you’re bidding.

Where a metal rabbit cage shines

- Commercial rabbit farms: higher density, organized manure handling, faster walk-throughs.

- Backyard keepers: cleaner floors, less gnawing; kids won’t snag fingers on rough edges.

- Breeding/research: controlled biosecurity, easy disinfection between cycles.

Advantages people report: fewer sore hocks thanks to smooth step nets, 5–8% feed savings from better feeder placement, and about 20–30% quicker cleaning. I’ve heard that last claim a dozen times—different provinces, same story.

Vendor options (quick comparison)

| Vendor | Material/Coating | Customization | Lead Time | Certs/Docs | After-Sales |

| Anping maker (this model) | Q235; HDG ≈ 50–90 µm | Tier count, mesh, feeders, logos | 15–28 days | ISO 9001; SGS tests | Spare kits; online support |

| Local OEM | Mixed; often electro-galv | Limited SKUs | Stock/7–14 days | Basic QC sheets | Walk-in service |

| Marketplace brand | Light wire; paint | Minimal | 3–7 days | None/limited | Email only |

Customization and compliance

Options: tier count, aisle width, nipple drinkers vs. cups, heavier step nets for large breeds, and corrosion packages for coastal barns. Documentation can include ISO 9001, material certs, and salt spray data. Welfare alignment with OIE and EU 98/58/EC is increasingly requested; this metal rabbit cage can be spec’d with rounded edges and wider resting zones to help.

Field notes (mini case studies)

- Shandong breeder, 1,200-doe expansion: swapped in this metal rabbit cage stack, reported ~6% feed savings and 25% faster wash-downs over 90 days (better drainage on fecal plates, they said).

- Mazovia backyard cluster, PL: two-tier kits with HDG finish; after a wet winter, no red rust at welds, and paw issues dropped (anecdotal, but consistent across three households).

Final take

What sets this metal rabbit cage apart is the balance: solid welds, honest zinc thickness, and modular bits you can replace without scrapping the frame. If you’re visiting the source, note the base: Jinwang Western Street, Industrial Zone, Anping County, Hengshui, Hebei—old-school wire territory. To be honest, that matters.

Authoritative references

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel products.

- ASTM A641/A641M: Zinc-Coated (Galvanized) Carbon Steel Wire.

- ISO 9227: Corrosion tests in artificial atmospheres—Salt spray tests.

- OIE (WOAH) Terrestrial Animal Health Code – Animal Welfare provisions for farmed rabbits.

- Council Directive 98/58/EC concerning the protection of animals kept for farming purposes.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025