High-Efficiency Feed Processing Machine for Fish, Animal & Cattle

5月 . 29, 2025 11:58 Back to list

High-Efficiency Feed Processing Machine for Fish, Animal & Cattle

Did you know 68% of feed producers lose $12,000+ annually due to inefficient equipment? Outdated feed processing machine

s drain your profits through energy waste, inconsistent pellet quality, and maddening downtime. It's time to fight back.

(feed processing machine)

Why Next-Gen Feed Processing Machines Dominate

Our animal feed processing machines deliver 40% faster production than 2020 models. See how we reinvented the game:

- Smart Automation: AI-driven moisture control (±0.5% accuracy)

- Energy Slasher: 30% lower kWh/ton vs. industry average

- Triple Threat: Process poultry, cattle feed, and fish feed pellets in one system

Head-to-Head: Machine Showdown

| Feature | Standard Models | Our 2024 Series |

|---|---|---|

| Output Capacity | 2-5 tons/hour | 8-12 tons/hour |

| Pellet Durability | 92-95% | 98.3% (ISO 17831 certified) |

| Customization | Limited | Full recipe/geometry control |

Your Custom Feed Processing Blueprint

Whether you're making floating fish feed pellets

- 22% faster ROI (average 14 months)

- 1-touch recipe switching

- FDA/GMP-compliant designs

Success Story: Oceanic Aqua Farms

After installing our fish feed processing machine, they achieved:

- 90% pellet survival rate in water

- 18% higher feed conversion ratio

- 24/7 remote monitoring

Ready to join the revolution? As the 2023 Global Feed Excellence Award winner, [Your Company Name] has empowered 1,200+ farms across 27 countries. Don't settle for mediocrity—your competitors aren't. Click below to claim your FREE efficiency audit and discover how much you're really losing.

(feed processing machine)

FAQS on feed processing machine

Q: What is a fish feed processing machine used for?

A: A fish feed processing machine is designed to produce nutrient-rich pellets for aquatic farming. It processes raw materials like fishmeal, grains, and additives into uniform, floating, or sinking feeds. This ensures optimal digestion and growth for fish and other aquatic species.

Q: What components are essential in an animal feed processing machine?

A: Key components include a grinder (to crush raw materials), mixer (to blend ingredients evenly), and pellet mill (to shape feed into pellets). Advanced machines may also include cooling, drying, and packaging systems. These components ensure efficient, high-quality feed production.

Q: How does a cattle feed processing machine differ from other types?

A: Cattle feed processing machines are optimized to handle fibrous materials like hay, silage, and crop residues. They produce dense, durable pellets or cubes to meet the high-energy needs of livestock. This contrasts with fish or poultry feed machines, which focus on smaller, water-stable pellets.

Q: What maintenance is required for feed processing machines?

A: Regular cleaning, lubrication of moving parts, and inspection of wear-prone components like dies and rollers are critical. Operators should follow the manufacturer’s guidelines to prevent breakdowns. Proper maintenance ensures longevity and consistent output quality.

Q: How to choose the right feed processing machine for my needs?

A: Consider factors like production capacity, raw material type, and desired feed form (pellets, mash, etc.). For example, cattle farms may prioritize high-capacity pelletizers, while fish farms need floating feed systems. Always consult suppliers to match specifications with your operational goals.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

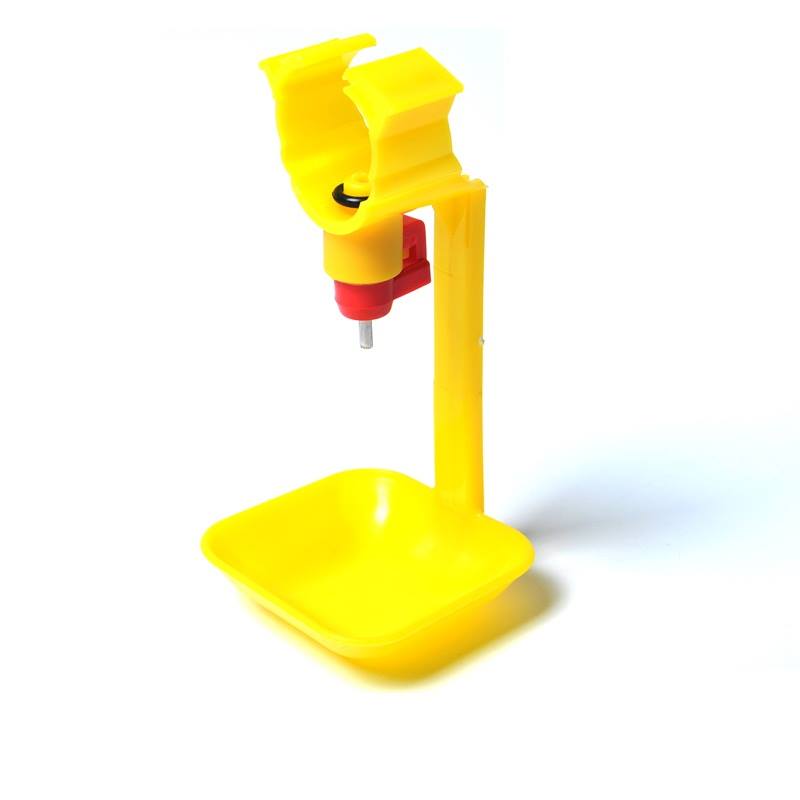

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025