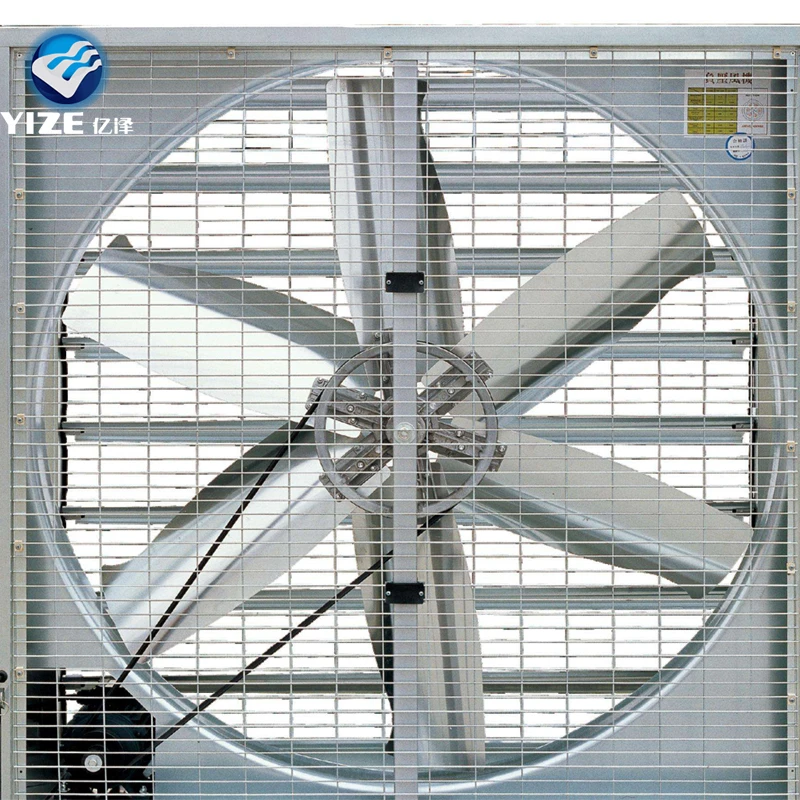

Maintaining optimal environmental conditions is crucial for poultry health, productivity, and operational efficiency. Our comprehensive range of environmental control equipment is designed to address key challenges in ventilation, waste management, and temperature regulation. The exhaust fan with louvers provides intelligent airflow management, automatically adjusting to maintain consistent air exchange while preventing backdrafts. Its aerodynamic design ensures energy-efficient operation, crucial for maintaining air quality in densely stocked poultry houses.

For effective waste removal, our manure belt cleaning system offers a hygienic and labor-saving solution. This automated system continuously removes droppings from beneath cages, reducing ammonia levels and minimizing disease risks. The durable belt material and precision-cleaning mechanism ensure long-term reliability with minimal maintenance. Alternatively, farms requiring a different approach can utilize our manure scraper system, which employs heavy-duty blades to systematically clear waste from concrete floors, ideal for open-house poultry operations.

Temperature control is addressed through our high-performance evaporative cooling pads for poultry, which leverage the natural cooling effect of water evaporation to maintain comfortable conditions during hot weather. The cellulose-based pads provide maximum surface area for efficient air cooling while resisting bacterial growth. When integrated with proper ventilation, these systems can reduce indoor temperatures significantly, preventing heat stress and improving flock performance.

-

-

obere mkpọtụ griin haus fiberglass iyuzucha onye ofufe nwere louver

-

Evaporative pad jụrụ oyi mmiri ikuku oyi / anụ ọkụkọ jụrụ cell pad

-

-

poutry Nri nri belt/conveyor belt maka oyi akwa / broiler / ọkụkọ / batrị / oke bekee / ọbọgwụ onu

What is the Primary Purpose of the Louvers on a Whole House Fan?

The louvers on a whole house fan serve several critical functions that enhance the efficiency, safety, and overall performance of the ventilation system. Their primary purpose is to control airflow and prevent backdrafts when the fan is not in operation. When the fan is turned off, the louvers automatically close, forming a tight seal that blocks outside air, dust, insects, and debris from entering the poultry house. This is particularly important in maintaining biosecurity and preventing contamination that could affect bird health.

Another key role of louvers is to improve energy efficiency. By sealing tightly when closed, they prevent heat loss during colder months and keep conditioned air inside, reducing the workload on heating systems. Conversely, when the fan is active, the louvers open fully to allow maximum airflow, ensuring optimal ventilation and air exchange. This dynamic operation helps regulate indoor temperatures and humidity levels, creating a healthier environment for the animals.

Louvers also contribute to noise reduction and structural protection. Without louvers, strong winds or storms could force air backward through the fan, potentially damaging the motor or causing unnecessary noise. The louvers act as a barrier, preventing wind-driven rain or snow from entering the building, which is especially important in regions with extreme weather conditions.

In poultry houses, where proper ventilation is crucial for ammonia control and respiratory health, louvers ensure that the exhaust system works efficiently. They help maintain consistent negative pressure ventilation, directing fresh air in through designated inlets while allowing stale, moisture-laden air to exit through the fans. This controlled airflow minimizes drafts and cold spots, promoting uniform temperature distribution throughout the house.

Poultry Manure Belt System or Poultry Manure Scraper? Which One Suits You?

Choosing between a poultry manure belt system and a manure scraper system depends on several factors, including farm size, housing design, labor availability, and long-term maintenance preferences. Both systems are designed to efficiently remove waste, but they operate differently and offer distinct advantages depending on the farming operation.

A manure belt system is commonly used in cage-layer poultry houses where birds are housed in stacked cages. This system consists of a continuous conveyor belt installed beneath the cages that moves manure to a centralized collection point. One of its biggest advantages is automation—since the belt operates on a timer, it requires minimal manual intervention, reducing labor costs. Additionally, because the manure is collected and transported immediately, it helps reduce ammonia levels and moisture buildup, improving air quality and bird health. The system is also hygienic, as the manure does not accumulate inside the house, lowering the risk of disease outbreaks. However, belt systems require regular maintenance to prevent jamming or wear and may have higher upfront costs compared to scrapers.

On the other hand, a manure scraper system is typically used in floor-raised or open poultry houses, where birds are kept on litter or slatted floors. This system uses a motorized scraper blade that moves along the floor, pushing manure into a collection pit or cross auger. The primary advantage of a scraper system is its durability and ability to handle large volumes of manure, making it ideal for broiler or breeder farms. Unlike belt systems, scrapers can handle wetter manure and are less prone to mechanical failures. However, they may require more frequent cleaning and can generate higher ammonia levels if manure is not removed quickly enough.

Evaporative Cooling Pads for Air Cooling in Poultry and Pig Houses

Evaporative cooling pads are a highly effective and energy-efficient solution for managing heat stress in poultry and pig houses, particularly in hot and dry climates. These systems work on the principle of water evaporation, where air passing through moistened cellulose pads is cooled before entering the barn, reducing indoor temperatures by 5°F to 15°F (3°C to 8°C).

One of the primary benefits of evaporative cooling pads is their ability to maintain optimal animal comfort during extreme heat. Poultry and pigs are highly susceptible to heat stress, which can lead to reduced feed intake, lower weight gain, and even mortality. By providing a consistent flow of cooled air, these pads help regulate body temperature, ensuring that animals remain productive even in high temperatures.