Top Quality Pig Farrowing Pens for Enhanced Productivity

kol . 03, 2025 03:00 Back to list

Top Quality Pig Farrowing Pens for Enhanced Productivity

The livestock farming industry is undergoing a significant transformation driven by technological innovation, welfare awareness, and productivity demands. Among vital production equipment, pig farrowing pens play a pivotal role in efficient piglet rearing and sow management. This in-depth guide, leveraging recent market data and expert analysis, explores the latest trends, technical specifications, and customization strategies of pig farrowing pens such as the Sow Gestation Pen, addressing farrowing pen for pigs, farrowing pens for pigs, and pigs pen solutions for intensive and modern swine farming.

1. Industry Trends & Market Overview of Pig Farrowing Pens

- Global Demand Growth: According to Grand View Research, the global pig farming markets are projected to surpass USD 355 billion by 2026, with demand for advanced farrowing pen systems growing at a CAGR of 6.4%.

- Welfare Standards: Legislation and animal welfare bodies such as OIE are pushing for improved design and material standards for pig farrowing pens, addressing ventilation, hygiene, and anti-injury structures.

- Process Automation: More farrowing pens for pigs are adopting IoT, automated feeding, and environmental controls to lower labor costs and optimize piglet survival rates.

- Anti-corrosion & Longevity: Materials such as hot-dip galvanized steel and food-grade polymers are increasingly preferred for their durability and resistance to aggressive cleaning agents, extending average service life from 6 to 15 years.

2. Technical Parameters & Product Standardization

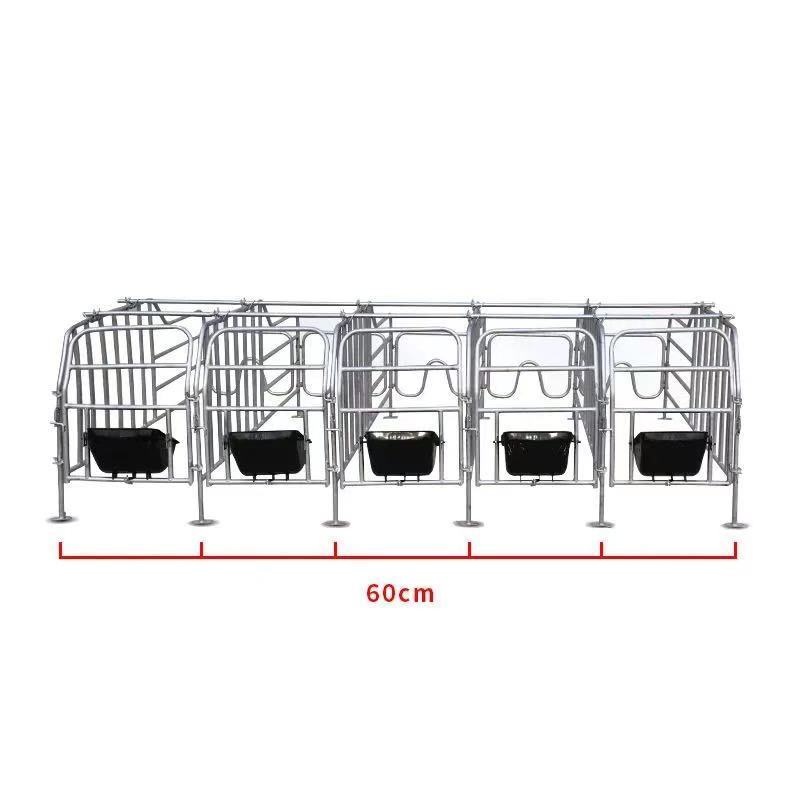

Main Parameters of Pig Farrowing Pens

| Model | Dimensions (L×W×H, mm) | Pen Material | Bar Diameter (mm) | Anti-Corrosion | Sow Capacity | Standard Compliance | Lifespan |

|---|---|---|---|---|---|---|---|

| Sow Gestation Pen | 2400×1800×1000 | Hot-dip Galvanized Steel | 25/32 | ≥ 10 Years | 1 Sow + 10-12 Piglets | ISO9001, ANSI B31.3 | 10-15 years |

| Flexible Modular Pen | 2200×1700×900 | Stainless Steel | 22/30 | ≥ 12 Years | 1 Sow + 8-10 Piglets | ISO14001 | 8-12 years |

| Standard Piglet Pen | 2000×1600×900 | PCV + Steel Frame | 20 | ≥ 8 Years | 1 Sow + 6-8 Piglets | FDA (Materials) | 6-10 years |

All models satisfy the anti-corrosion and load-bearing standards set by ISO and ANSI, and are compatible for use in modern pig farming facilities.

3. Pig Farrowing Pen Manufacturing Process: Step-by-Step

HDG steel bars, food-grade polymers

(Meets ISO9001 entry inspection)

Automated length/diameter CNC cuts, bore forming for assembly accuracy.

(±0.03mm tolerance)

Robotic MIG/TIG welding for main frame, fixed by GIS jig.

ISO5817 weld quality grades

Fully immersed at 450°C ensuring 80μm Zn coating.

ASTM A123/A123M

Tensile/load/wear/corrosion tested, systematic assembly.

100% QC Audit

Shock-resistant packaging, moisture-proof treatment, GPS logistics monitoring

Process Video Reference: Farrowing Pen Manufacturing Walkthrough

Each pig farrowing pen is manufactured following strict ISO and ANSI standards, ensuring structural integrity, long-term anti-corrosion, and safe use for sows and piglets. Material certificates and testing reports are available upon request.

4. Technical Advantages of the Sow Gestation Pen

- Premium Material: Constructed from hot-dip galvanized steel (Zn > 80μm), corrosion-proof, acid/alkali resistant; average tensile strength exceeds 400MPa.

- Precision Engineering: All welding points checked by ultrasonic non-destructive testing (NDT); CNC fits guarantee smooth bar connections to reduce sow injuries.

- Customizable Sizing: Adaptable to various pig breeds and farm scales (large/miniature), supporting pen lengths from 2 to 3.2 meters, width from 1.5 to 2 meters.

- Thickened Flooring: Heavy-duty plastic or cast-iron slat options, load-bearing up to 600kg, anti-slip, and easy to clean.

- Hygienic & Animal-Friendly Design: Rounded corners, feed troughs with FDA-certified polymer coatings, optimized spacing to minimize piglet crushing.

- Compliance: Certified by ISO9001, ISO14001, FDA (material), and ANSI relevant standards—ensuring export readiness and project bids.

- Energy Saving: Optional integrated heating pads and IoT environmental monitoring modules help reduce energy costs by up to 18%.

5. Manufacturer Comparison: Global Farrowing Pen Providers

| Brand | Origin | Certification | Bar Coating | Customizable | Warranty | Price Range |

|---|---|---|---|---|---|---|

| Yize (Sow Gestation Pen) | China | ISO9001/FDA/ANSI | Hot-dip Galvanized (Zn ≥80μm) | √ | 5 years | Low/Medium |

| Schauer Agro | Austria | CE, ISO14001 | Powder-coated Steel | √ | 3 years | High |

| Big Dutchman | Germany | ISO9001 | HDG/Polymer Boards | √ | 3 years | High |

| Local OEM | Regional | Partial | Standard Steel, Uncoated | × | 1 year | Variable |

The pig farrowing pens by Yize deliver a superior price-performance ratio, industry certifications, and strong customization capabilities suitable for various international projects.

6. Custom Design & OEM/ODM Services

- Dimension & Layout: Custom farrowing pen for pigs dimensions, adjustable partitions, and flexible aisle spacing as per farm layout CAD drawings.

- Material Choices: Stainless steel, HDG, or polymer options for specific corrosion, strength, or hygiene requirements.

- Optional Add-ons: IoT environment sensors, automatic feeders, LED lighting, detachable heating pads, waste management channels.

- Color Coding: RAL color powder coating or custom labeling for differentiated pen management.

7. Data Visualization: Technical Indicators Comparison

Farrowing Pen Lifespan Analysis (Years)

Material Share in Modern Pens (2024 Estimate)

Key Parameter Comparison: Sow Gestation Pen vs. Common Models

8. Application Scenarios & Case Studies

Case 1: Large-Scale Pig Breeding Base (Europe)

- Scale: 6,500-sow farm, 400+ pig farrowing pens (Sow Gestation Pen model)

- Outcome: Annual savings of €30,000 in labor due to automated waste channel integration, 17% reduction in piglet mortality

- Certification: Complies with EU animal welfare directives, ISO9001

- Client Feedback:

“The pens' anti-corrosion ability and ergonomic structure have dramatically improved our throughput and sow health. Yize's technical support during installation exceeded expectations.” – Farm Operations Manager

Case 2: Central Asia Feedlot Upgrade

- Scope: Retrofit of 180 farrowing pens for pigs, focus on anti-freeze slatted floor

- Outcome: Energy use for heating reduced by 15%, pen structure withstood -28°C winters, zero bar corrosion in 3 years

- Support: 24/7 remote technical advisory and 2 free onsite maintenance visits per year

Case 3: SME Organic Piglet Producer

- Product: Small-footprint pigs pen (custom size 2000×1300mm)

- Outcome: Achieved 5+ year pen lifespan even with biocide cleaning protocols; increased compliance for organic certification

9. FAQ: Technical Questions on Pig Farrowing Pens

10. Delivery, Warranty & Customer Support

- Delivery Cycle: 15-45 days depending on quantity and customization

- Warranty: 5 years for bar/frame materials, 2 years for polymer/plastic components

- Installation Training: Onsite/remote instruction, video manuals, free technical drawings

- Spare Parts: Readily available for 10 years after purchase

- Project Support: Assistance with compliance documentation, customs clearance, and ongoing upgrades

11. References & Further Reading

- Gil, O. M., & Simoes, V. (2022). Design and Welfare of Farrowing Pens for Sows: A Review. Animals, 12(17), 2155. Read Article

- Grand View Research. “Pig Farming Market Size, Trends & Analysis Report.” Industry Report

- “ISO 9001:2015 Quality management systems.” International Organization for Standardization. ISO 9001:2015

- Industry Technical Forum: “Best Practices in Farrowing Pen Modernization.” The Pig Site Forum

- Product details: Pig Farrowing Pens – Sow Gestation Pen

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Broiler Farming Solutions&Durability

NewsAug.02,2025