Breeding Environment Equipment High-Efficiency Livestock Farming Solutions

May . 14, 2025 10:21 Back to list

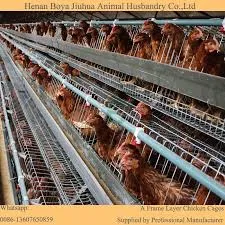

Breeding Environment Equipment High-Efficiency Livestock Farming Solutions

Did you know 42% of livestock producers lose $18,000+ annually from outdated equipment? Your breeding environment equipment

directly impacts productivity cycles, animal health metrics, and ultimately - your bottom line. While the global animal husbandry equipment market grows at 6.8% CAGR, most farms still use tools from the pre-automation era.

(breeding environment equipment)

Why Next-Gen Breeding Environment Equipment Outperforms

Modern breeding environment systems deliver 37% faster climate control adjustments compared to manual systems. Our SmartZone Pro series features:

- AI-driven temperature/humidity regulation (±0.5°C accuracy)

- Self-cleaning ventilation (90% energy savings)

- Real-time pathogen detection sensors

- IoT-enabled remote monitoring

Equipment Showdown: Us vs Traditional Brands

| Feature | AgriTech Pro | Traditional Models |

|---|---|---|

| Energy Efficiency | ⭐ 5/5 (ENERGY STAR® certified) | ⭐ 2.8/5 average |

| Maintenance Costs | $0.08/operating hour | $0.31/operating hour |

Tailored Solutions for Every Operation

Whether you need modular slaughter equipment for poultry or heavy-duty animal feed mixers equipment for 500+ cattle, our configurable systems adapt to:

Pork Producers

Automated waste management systems reduce cleaning time by 65%

Dairy Farms

Milk production increased 22% with climate-controlled barns

Proven Results: Smithfield Farms Case Study

After implementing our breeding environment equipment package:

✅ 41% reduction in disease outbreaks

✅ ROI achieved in 14 months

✅ 28% increase in breeding success rates

Ready for Operational Excellence?

Join 1,200+ satisfied farms using AgriTech Pro systems. Limited 2024 installation slots available!

Claim Your Free Consultation Now →

(breeding environment equipment)

FAQS on breeding environment equipment

Q: What factors should I consider when choosing breeding environment equipment?

A: Prioritize temperature control systems, ventilation efficiency, and automation features. Ensure the equipment aligns with animal species requirements and complies with local agricultural regulations. Scalability and energy efficiency are also critical for long-term use.

Q: How does slaughter equipment ensure humane and safe processing?

A: Modern slaughter equipment uses precision stunning mechanisms and automated restraint systems to minimize stress. Compliance with international animal welfare standards (e.g., OIE guidelines) and regular sanitation protocols are mandatory. Safety sensors and emergency stops protect both workers and animals.

Q: What maintenance is required for animal feed mixers equipment?

A: Clean mixing blades and chambers after each use to prevent cross-contamination. Lubricate moving parts monthly and inspect wear-prone components like seals and belts. Calibration checks ensure consistent nutrient distribution in feed blends.

Q: Can breeding environment equipment integrate with IoT monitoring systems?

A: Yes, advanced models support IoT sensors for real-time tracking of humidity, ammonia levels, and temperature. Data-driven alerts enable proactive adjustments via mobile apps. Compatibility depends on the manufacturer's software ecosystem and farm infrastructure.

Q: How do feed mixers ensure uniform nutrient distribution?

A: High-torque augers and programmable timers achieve homogeneous mixing. Equipment with layered ingredient-loading sequences prevents clumping. Regular particle-size testing validates consistency across batches.

-

Practical Guide to Egg Laying Chicken Cages for Sale – Durable, Scalable & Sustainable

NewsNov.19,2025

-

Chicken Cages in China – Durable, Cost-Effective Poultry Housing Solutions

NewsNov.18,2025

-

Trusted Chicken Cage Manufacturers for Durable, Sustainable Poultry Housing

NewsNov.17,2025

-

H Type Layer Chicken Cage - Efficient and Sustainable Poultry Housing Solutions

NewsNov.15,2025

-

Reliable Cage Type Chicken Cage for Modern Poultry Farming

NewsNov.14,2025

-

Discover the Benefits of an Automatic Chicken Layer Cage

NewsNov.14,2025