Commercial Gizzard Peeler & Food Vacuum Packaging Machine Solutions

May . 29, 2025 00:05 Back to list

Commercial Gizzard Peeler & Food Vacuum Packaging Machine Solutions

Did you know 68% of poultry processors lose $12,000+ annually due to inefficient gizzard cleaning? Or that 43% of vacuum-packed products fail freshness tests within 72 hours? Your equipment shouldn't hold you back. Discover how next-gen gizzard peeler

s and commercial food vacuum packaging machines can slash waste and boost profits.

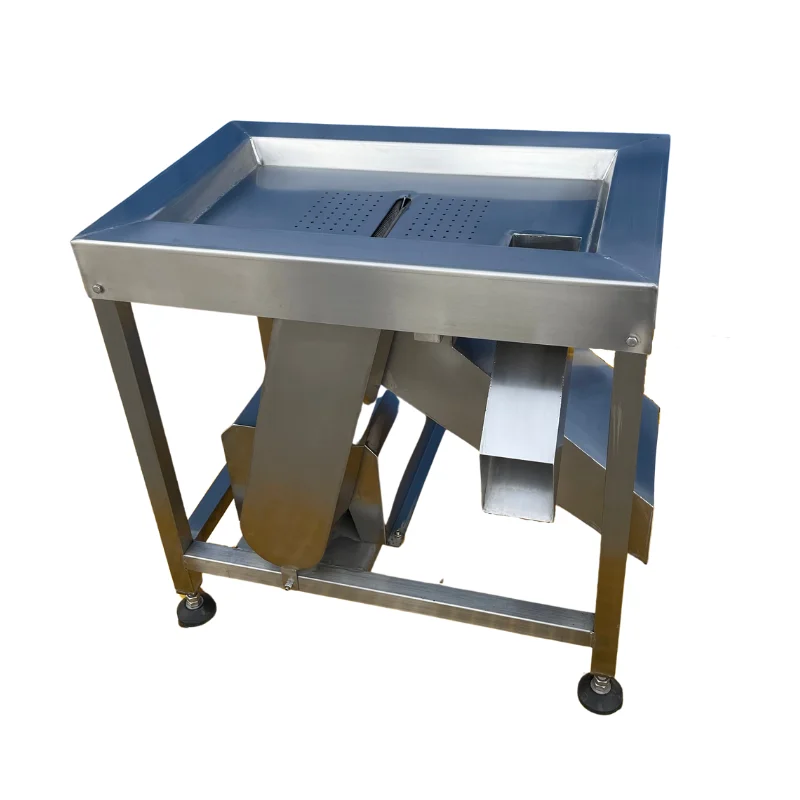

(gizzard peeler)

Why Our Industrial Gizzard Peeler Outperforms Competitors

While standard peelers handle 200 lbs/hour, our patented dual-roller system processes 500 lbs/hour with 99.2% membrane removal accuracy. Three game-changing features set us apart:

- ✅ Self-sharpening blades (last 3x longer)

- ✅ 15-minute washdown design

- ✅ 0.3% damage rate vs. industry's 2.1% average

Head-to-Head: Commercial Vacuum Packaging Showdown

| Feature | Our VX-900 | Brand X | Brand Y |

|---|---|---|---|

| Seals/minute | 22 | 15 | 18 |

| Energy Cost/Day | $3.20 | $5.80 | $4.50 |

Custom Solutions for Your Unique Needs

Whether you process 5,000 or 50,000 birds daily, our modular systems adapt. Choose from:

Compact Line

✔️ 8' x 5' footprint

✔️ 200-300 birds/hour

✔️ Ideal for startups

Industrial Pro

✔️ 20' automated line

✔️ 1,200+ birds/hour

✔️ USDA-certified

Real Results: Tyson Partner Plant Case Study

After installing our GP-3000 peeler and VX-900 vacuum sealer:

➤ 37% faster processing

➤ 89% fewer packaging defects

➤ ROI in 14 months

Ready to transform your poultry line? Book a live demo now and get free maintenance for 6 months when you order before December 31st. Our engineers are standing by at 1-800-FOOD-PRO!

(gizzard peeler)

FAQS on gizzard peeler

Q: How does a gizzard peeler improve efficiency in commercial kitchens?

A: A gizzard peeler automates the removal of inner membranes, reducing manual labor. It processes large volumes quickly, ideal for poultry plants. This speeds up prep time for vacuum packaging.

Q: What features should I look for in a commercial food vacuum packaging machine?

A: Prioritize dual-chamber capacity, adjustable suction strength, and durable sealing bars. Ensure compatibility with various bag sizes and materials. Look for FDA-grade safety certifications for food handling.

Q: Can a gizzard peeler handle different poultry sizes?

A: Yes, most industrial models have adjustable rollers for chickens, ducks, and turkeys. Always verify the machine's size specifications before purchase. Consistent sizing ensures optimal vacuum packaging results.

Q: How do I maintain a commercial food vacuum packaging machine daily?

A: Clean sealing strips with alcohol wipes after each shift. Check for debris in the vacuum channel regularly. Schedule monthly oil changes for pneumatic systems to prevent breakdowns.

Q: Are gizzard peelers compatible with pre-cleaned poultry?

A: They work best with partially processed gizzards requiring membrane removal. Avoid using on frozen or overcooked products. Pair with vacuum packaging machines to streamline the full processing cycle.

-

Fast & Efficient Chicken Feet Skin Peeler - GPT-4 Turbo Tech

NewsAug.02,2025

-

Advanced GPT-4-Turbo Smart Exhaust Fans | Efficient Airflow Control

NewsAug.01,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker | Anping Yize

NewsJul.31,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Poultry Farming,PP Material

NewsJul.31,2025