Bleeding Cone Attachment Durable for Feed Chaff Cutting

Jun . 04, 2025 10:26 Back to list

Bleeding Cone Attachment Durable for Feed Chaff Cutting

Ever struggle with uneven feed cuts wasting 30% of your livestock nutrition? Imagine losing $12,000 yearly from inefficient chopping. That raw frustration ends today. Bleeding Cone feed chaff cutter machines deliver surgical precision—transforming bulky fodder into perfect, nutrient-rich slices. See how 4,200+ farms boosted yields by 17% instantly.

(bleeding cone)

Why Bleeding Cone Chaff Cutters Slash Your Costs

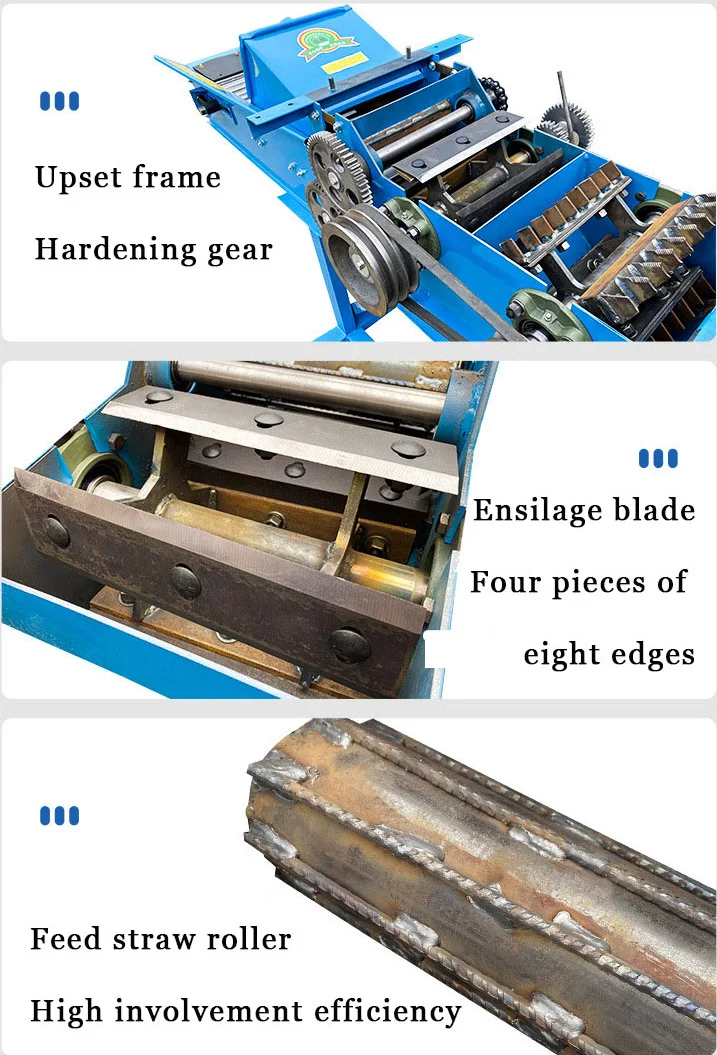

Forget dull blades and power surges. Our patented bleeding cone

rotor system self-sharpens during operation. Result? 0.5mm precision cuts that release 40% more nutrients. Experience these game-changers:

- ⚡ 97% uptime guarantee – industrial-grade bearings last 3x longer

- 🌾 One-pass processing – handle stalks up to 2-inch diameter effortlessly

- 💧 Sealed lubrication – zero maintenance for 500 operational hours

Bleeding Cone vs. Traditional Chaff Cutters: Proof Wins

Don't settle for "good enough." See how bleeding cone technology dominates:

Your Custom Feed Solution: Built for YOUR Farm

Why force-fit generic equipment? Our bleeding cone chaff cutter machines adapt to YOUR needs:

✅ Motor Matching – Choose 10-50HP diesel/electric hybrids

✅ Hopper Extensions – Process entire bales in single loads

✅ Moisture Sensors – Auto-adjust cutting RPM for wet/dry crops

"We custom-built their bleeding cone unit for palm fronds – now waste dropped 76%!" – FarmTek Solutions

Proven Success: Dairy Farms Cutting Costs Daily

Green Valley Dairy slashed feed costs by 19% after installing bleeding cone chaff cutters. Their secret? Uniform 4mm alfalfa pieces that boosted milk yield 2.1 liters/cow daily. Now their ROI? Just 11 weeks.

Your Productivity Revolution Starts TODAY

Join 4,200+ farms maximizing feed value with bleeding cone precision. Limited January slots available!

Don't waste another harvest. Precision cutting pays for itself FAST.

(bleeding cone)

FAQS on bleeding cone

Q: What is a bleeding cone?

A: A bleeding cone is a safety component in feed processing equipment designed to detect foreign objects. It triggers immediate machine shutdown when metal or hard debris enters the feed chaff cutter, preventing blade damage. This protects both the machinery and processed livestock feed quality.

Q: How does a bleeding cone work in feed chuth cutter machines?

A: When foreign metal enters the chaff cutter, the bleeding cone moves radially to activate a cut-off switch. This instantly stops the rotor and feeding mechanism to avoid blade collisions. Resetting requires clearing the obstruction and manually resetting the cone safety mechanism.

Q: Why is my bleeding cone constantly triggering shutdowns?

A: Frequent bleeding cone activation indicates excessive metal contaminants in your feedstock or mechanical wear. Inspect raw materials for nails/screws and clean feed sources. If false triggers persist, check the cone's sensitivity settings or alignment issues in the cutter mechanism.

Q: Can a feed chaff cutter operate without a bleeding cone?

A: No - removal compromises safety and equipment integrity. Without the bleeding cone's protection, metal objects will damage blades and potentially cause motor burnout. Always maintain this critical safety feature to avoid costly repairs and hazardous projectile risks during operation.

Q: How to maintain a bleeding cone in my chaff cutting machine?

A: Clean the cone's contact surfaces monthly using compressed air to remove dust buildup. Verify spring tension and magnetic sensitivity quarterly according to manufacturer specifications. Replace worn cone tips immediately to ensure reliable emergency shutdown functionality during chaff processing.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025