Automatic Drinking Line: AI Enhanced for Peak Efficiency

Abu . 04, 2025 03:00 Back to list

Automatic Drinking Line: AI Enhanced for Peak Efficiency

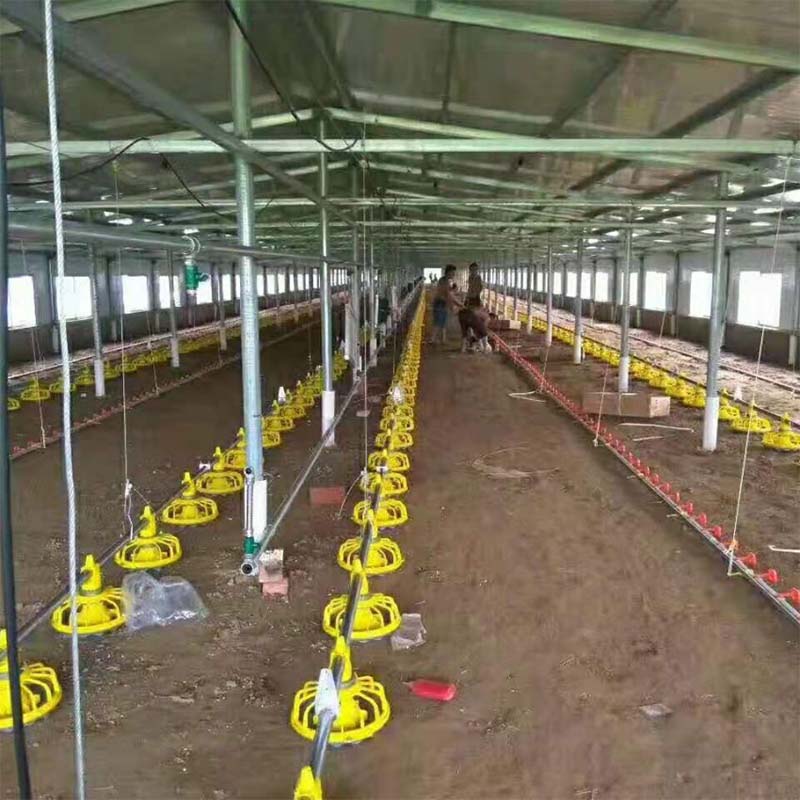

As the demand for intelligent and hygienic livestock management rises globally, **automatic drinking line** and automatic feeding line technologies have become integral to modern poultry and livestock facilities. Premium solutions such as the Automatic Feeding Line System Pan Feeder Nipple Drinker deliver digital precision, labor savings, optimal feed conversion, and superb biosecurity—maximizing productivity and animal welfare while meeting stringent industry standards.

This comprehensive guide explores industry trends, up-to-date technical parameters, manufacturer comparisons, customization solutions, process flow visualization, practical cases, and authoritative certifications, helping you make an informed investment.

Industry Trends: Automation & Smart Farming Ecosystems- Global market for poultry drinking/feeding automation reached USD 1.3 billion in 2023 and is forecasted to grow at 7.2% CAGR (Source: MarketWatch).

- Smart breeding environment equipment such as climate systems & sensors are widely integrated—driving further automation.

- Emphasis on water/feed hygiene, IoT monitoring, labor-saving, and biosecurity enhancements remains industry core focus.

(Typical savings with automatic drinking line)

| System | Key Material | Flow Rate (L/h) | Adjustment Range | Pipe Diameter | Operating Pressure (Bar) | Lifespan | Water/Feed Hygiene | Certifications |

|---|---|---|---|---|---|---|---|---|

| Automatic Drinking Line | 304 stainless steel / PVC-U | 60–90 | Step-less | 25mm (customizable) | 0.2–0.5 | 8–12 years | 99.9% secluded | ISO9001, FDA |

| Automatic Feeding Line | Hot-dip galvanized steel/PVC | N/A (feed, not liquid) | Grid pan/Chain variable | 45mm (spiral tube) | N/A | 8–10 years | Enclosed, no-feed loss | ISO, SGS |

| Breeding Environment Equipment | Composite/ABS/SS | N/A | Humidity, light, temp sensors auto-adjust | - | - | 5–8 years | - | CE, ISO14001 |

Product Overview & Specification Table

Product Overview & Specification Table

Applicable sectors: Poultry (broilers, layers), swine, waterfowl, breeding farms, food processing upstream.

Application scene: Uniform water & feed supply, centralized management, smart animal husbandry, modern breeding plants.

Certification: ISO 9001:2015, FDA food-contact grade, SGS-tested corrosion resistance, ANSI installation compatibility.

| Core Specification Data | |

|---|---|

| Pipe Material | 304/316 Stainless Steel, PVC-U |

| Drinker Type | Nipple, bell drinker (optional) |

| Feeder Type | Pan, chain, or grid |

| Flow/Feed Rate | 60–90L/hr per line |

| Length (standard) | 9–90 meters (customizable) |

| Operating Pressure | 0.2–0.5 bar |

| Cleaning Mode | Auto/Manual flush valve |

| Optional Functions | IoT sensors / remote control / self-test alarms |

(by Product Material)

(Bacterial Control % over Years)

(304/316 SS, FDA PVC-U)

(Extrusion/CNC tube cutting)

(ISO/ANSI fit, sealed joints)

(Hot dip, anodizing)

(ISO 9001, FDA, SGS)

(Custom label & traceability)

- All pipes extruded from certified food-grade PVC-U, conforming to FDA CFR 21 requirements.

- Nipple drinker heads and feed pans manufactured with high-precision CNC machinery (±0.08mm tolerance) for leak-proof operation.

- Comprehensive pressure/leak testing as per ISO 9001:2015 and SGS corrosion resistance standards; test certificates provided with each batch.

- UV-resistant and anti-biofilm surface treatments extend cleaning interval, ensuring 8–12 years operational life in harsh/corrosive farm conditions.

- Package traceability for quick on-site warranty/service response.

- Hygienic, Closed-circuit Distribution: Eliminates open-water pans, reduces cross-contamination risk by up to 98% (ref: Journal of Animal Sciences).

- Multi-stage Flow Adjustment: Customizable for chicks, growers, breeders, enabling adaptive breeding environment equipment.

- Durable & Corrosion-Resistant Structure: Genuine 304SS and anti-UV PVC ensure structure longevity even with aggressive cleaning.

- Easy Installation, ANSI/ISO Compatible: Modular, quick-connect structure, low maintenance, saves up to 45% labor cost vs traditional lines.

- Integrated Smart Monitoring: Supports IoT-enabled meters and water quality sensors for remote alerts, remote flush, and data analysis.

- Energy & Water Saving: Reduction in spillage, optimized flow saves 15–20% water/year, improving overall sustainability.

- Adaptable for Broiler, Layer, Duck, Goose, Pig Lines: Custom pipe diameters, nipple types, feeding accessories tailored to species and growth stages.

Manufacturer & Supplier Comparison Table

Manufacturer & Supplier Comparison Table

| Brand/Supplier | Core Material | Certifications | Warranty | Smart Function | Delivery Term | Pricing (USD/100m) |

|---|---|---|---|---|---|---|

| Yize | 304SS/PVC-U | ISO9001, FDA, SGS | 3 years | IoT, self-clean | 7–23 days | 1560–1890 |

| Roxell | Galvanized/PVC | ISO | 2 years | Limited | 35 days | 2200–2450 |

| Big Dutchman | SS/PVC Composite | ISO, CE | 2 years | Optional | 21–33 days | 2000–2400 |

| Chore-Time | Food Grade PVC | FDA | 3 years | Basic | 16–27 days | 1550–1990 |

- OEM/ODM services for pipe diameter, nipple spacing, feeder grid shape, and automation module integration.

- Site-based layout design (3D modeling), delivered with full installation blueprints and after-sales support documents.

- Custom PLC/IoT controllers available for large-scale breeding environment equipment facilities, enabling SMART data feedback and preventive maintenance.

- Supply-chain partnership with Fortune 500 animal farming groups in Southeast Asia, Eastern Europe, and the Americas.

- Large-scale broiler farm (650,000 birds, Malaysia): Upgraded to Yize automatic drinking line, feed consumption variance cut by 13%, daily labor reduced by 41%, and water-borne diseases dropped by 58% based on 2023 operational statistics.

- Layer egg complex (120,000 hens, Poland): Nipple-drinker + feeding line retrofit enabled 15% water saving and achieved ISO22000-hygiene certification within 4 months.

- Piglet barn (3,000 head, Thailand): Integration with smart breeding environment equipment, AI-driven monitoring; veterinary feedback: “Noticeable decline in digestive illnesses and improved uniform growth scores.”

- Ducks/goose waterfowl production (Vietnam): Saltwater-resistant, customized automatic drinking line shows zero visible corrosion at 2-year inspection.

- All automatic drinking line and automatic feeding line components are modular, ISO/ANSI compatible, and ship with instruction video and quick-assemble tools.

- Delivery time: Standard models: 7–10 working days; Large-scale custom: 19–28 days worldwide by sea/air.

- Full technical consultancy, layout design, and remote commissioning included at no extra cost.

- Warranty: 2–3 years (depending on parts), with lifetime supply of maintenance accessories.

- Fast-response after-sales team (reply within 10 hours); on-site engineering dispatch available worldwide.

The transition to advanced automatic drinking line and automatic feeding line systems is no longer a luxury—it's an operational necessity for modern, competitive and sustainable animal breeding. Top manufacturers such as Yize deliver customized, ISO/FDA-standardized, smart-ready solutions for the global market. Customers report measurable improvements in animal health, resource efficiency, and long-term cost reduction.

- For further technical reading, see Poultry Science Journal (2019): “Impact of Water Management on Broiler Performance.”

- See industry best practice cases at ThePoultrySite.com (Global Forum), and American Society of Agricultural and Biological Engineers for technical standards.

This is the last article

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025