Looking for a Modern Poultry Breeding Cage to Boost Yield?

Oct . 01, 2025 11:05 Back to list

Looking for a Modern Poultry Breeding Cage to Boost Yield?

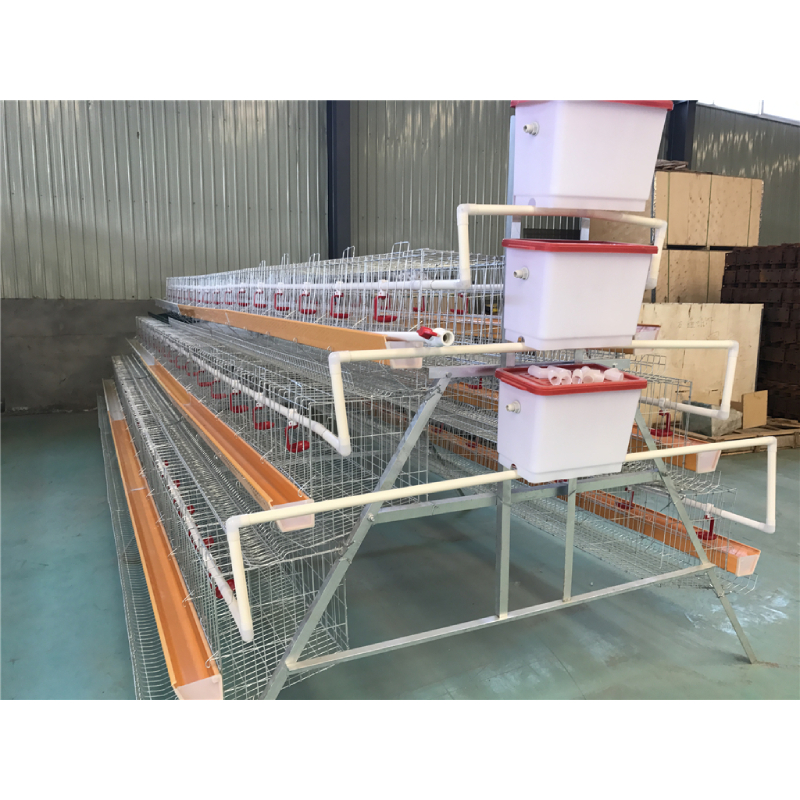

If you’re speccing a new poultry breeding cage, here’s what actually matters in 2025: durability, biosecurity, and automation readiness. I’ve walked enough farms—mud on the boots, ammonia in the air—to know small details add up. The model I’ve been watching lately is the “96,120,128,160 Birds Layer Poultry Battery Chicken Cages,” produced in Jinwang Western Street, Industrial Zone, Anping County, Hengshui, Hebei, China. It’s built for dense, hygienic layer production without beating up the birds—or your maintenance budget.

Industry trends (quick take)

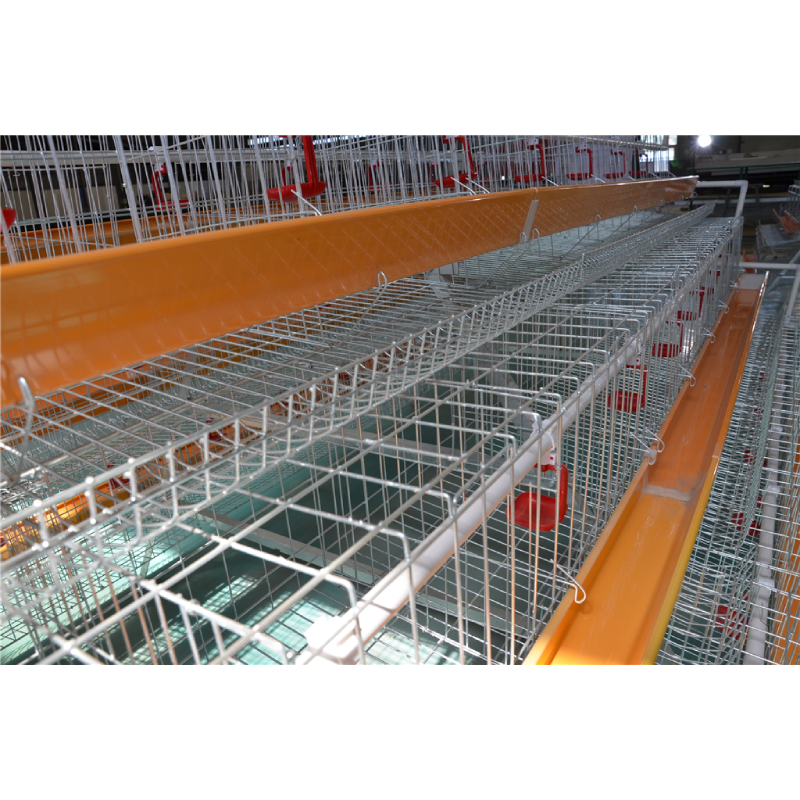

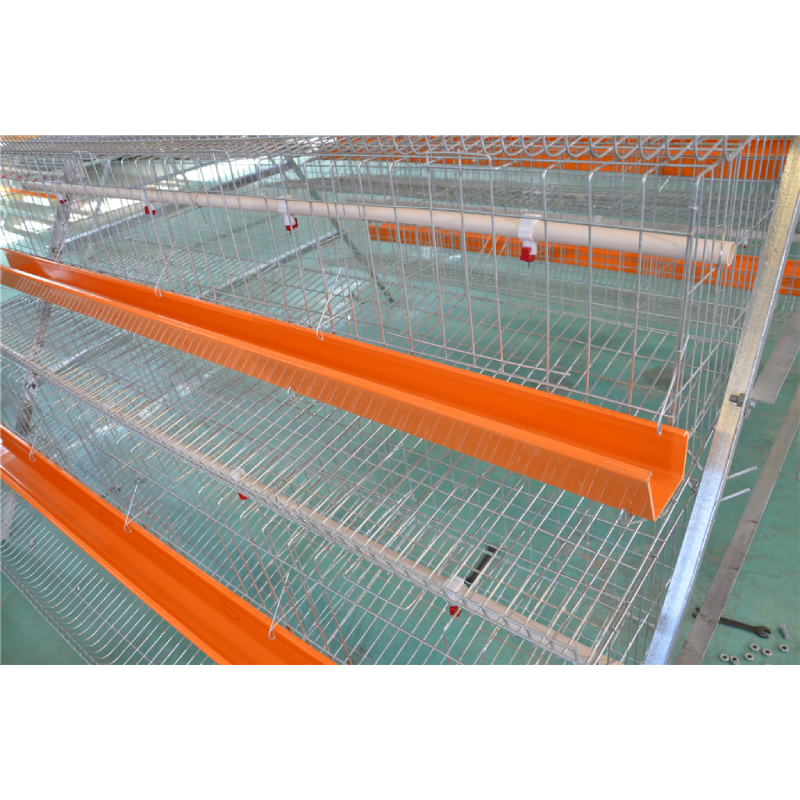

Automation is sliding from “nice-to-have” to standard: nipple drinkers, manure belts, egg collection rails, even optional chain feeders. Another shift: thicker galvanizing and smarter mesh geometry to cut foot lesions. And yes, welfare audits are stricter. Many customers say they’re moving to cages with better corrosion resistance and easier washdowns—because downtime kills margins.

Process flow, materials, and testing (how it’s actually made)

- Materials: low-carbon Q235 steel wire & frame; hot-dip zinc coating (ISO 1461) or Zn-Al alloy; UV-stable PP manure belts.

- Methods: CNC wire forming, resistance welding, post-weld hot-dip or heavy Zn-Al spray; passivation; bolted module assembly.

- Testing: salt-spray 480–720 h (ASTM B117), weld shear tests, dimensional checks ±1.5 mm, load deflection under 1.5× rated live load.

- Service life: ≈12–20 years depending on ventilation, litter moisture, and wash regimen.

- Industries: large-scale layer farms, breeding bases, integrators, and, surprisingly, upscaled backyard operations.

Product specs (real-world numbers)

| Model | Birds/Unit | Tiers×Rows | Module Size (L×W×H) | Wire Ø / Mesh | Coating |

|---|---|---|---|---|---|

| A3 | 96 | 3×4 | ≈1950×2100×1600 mm | 2.2–3.0 mm / 50×50–60 mm | Hot-dip Zn ≈60–80 μm |

| A4 | 120 | 4×4 | ≈1950×2200×2000 mm | 2.2–3.2 mm / 50×50–60 mm | Zn-Al alloy (enhanced) |

| A4+ | 128–160 | 4×5 | Custom length | Up to 3.5 mm / anti-scratch floor | HDG per ISO 1461 |

Notes: cage floor slope ≈7–9° for clean egg roll; nipple drinkers 2–3 per compartment; manure belt drive 0.75–1.5 kW/row (real-world use may vary).

Vendor comparison (what buyers actually ask me)

| Criteria | Yize Machine | Local Fabricator | Import Brand |

|---|---|---|---|

| Coating thickness | ≈60–80 μm HDG | 20–40 μm (varies) | 70–90 μm |

| Automation compatibility | Feeder/egg/manure lines ready | Partial | Full |

| Lead time | 3–5 weeks | 1–3 weeks | 6–10 weeks |

| Certifications | ISO 9001, CE, SGS | Varies | ISO/CE |

Applications and advantages

- Large farms: maximize birds per m² while keeping airflow consistent.

- Breeding bases: traceability and biosecurity corridors are easier to enforce.

- Backyard upgraders: modular units; fewer egg cracks, cleaner floors.

Advantages? Lower mortality, faster cleaning cycles, and, to be honest, fewer surprises on audit day. Many customers report 1–2% better egg integrity after switching to thicker wire floors.

Customization

Options include tier count, mesh opening for local breeds, added perches, galvanized or Zn-Al coating, and voltage-matched motors. Origin is documented on each crate: Anping County, Hengshui, Hebei, China—wire mesh capital, for good reason.

Case study (field notes)

A 20,000-bird layer site in Southeast Asia replaced aging frames with the 160-bird modules. Result after 6 months: cracked eggs down from 5.2% to 3.6%, manure moisture reduced ≈12% due to better belt tracking, and cleaning time dropped by roughly 25 minutes per row. The manager told me, “Feed conversion didn’t change much, but staff complaints sure did.” Fair point.

Compliance, welfare, and data

Designed to align with OIE guidance and EU-type welfare metrics for space, slope, and injury prevention (always validate locally). Lab panels show ≤0.8 mm average zinc loss per year in moderate ammonia conditions; that’s why service life estimates sit around 12–20 years.

If you need a robust poultry breeding cage that plays nicely with automation, this lineup is, I guess, the pragmatic choice. Just don’t skimp on ventilation and wash protocols—hardware is only half the story.

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- WOAH (OIE) Terrestrial Animal Health Code – Animal Welfare, Laying Hens (latest edition).

- EU Directive 1999/74/EC – Minimum standards for the protection of laying hens.

- ISO 9001:2015 – Quality management systems, manufacturing compliance.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025