Durable Pig Farrowing Pens: Maximize Piglet Safety & Growth

Sep . 13, 2025 08:00 Back to list

Durable Pig Farrowing Pens: Maximize Piglet Safety & Growth

Introduction to Advanced Swine Management Systems

In modern swine production, the efficiency and welfare of both sows and piglets are paramount for sustainable profitability. Central to achieving these goals are technologically advanced farrowing solutions. Specifically, high-quality pig farrowing pens are engineered to provide a secure, comfortable, and hygienic environment during the critical farrowing and lactation periods. These specialized enclosures are designed to maximize piglet survival rates, optimize sow health, and streamline farm management operations.

Our focus delves into the robust engineering, meticulous manufacturing, and strategic deployment of these essential farm structures, highlighting their indispensable role in enhancing productivity across commercial swine operations globally. The integration of durable materials, ergonomic design, and adherence to stringent quality controls ensures that these farrowing solutions meet the rigorous demands of contemporary agricultural practices.

Industry Trends in Swine Farrowing Solutions

The swine industry is undergoing a significant transformation, driven by evolving consumer demands, stricter animal welfare regulations, and the constant pursuit of operational efficiency. Key trends influencing the design and adoption of farrowing pen for pigs include:

- Enhanced Animal Welfare: A growing emphasis on sow and piglet welfare has led to innovations like "freedom farrowing" or "group farrowing" systems, providing sows more space to move, turn around, and interact. While traditional crates remain prevalent for safety, hybrid designs are gaining traction.

- Increased Automation and Sensor Technology: Integration of automated feeding systems, environmental control sensors (temperature, humidity, air quality), and even video monitoring for early detection of issues is becoming standard to optimize conditions and reduce manual labor.

- Hygiene and Biosecurity: Materials and designs that facilitate easy cleaning and disinfection are critical to prevent disease transmission. Slatted flooring, plastic or cast iron options, and elevated pen designs are optimized for waste removal.

- Modular and Customizable Designs: Farms require flexible solutions that can adapt to different building layouts, sow sizes, and management philosophies. Modular components allow for easier installation, modification, and expansion.

- Durability and Longevity: Investment in high-quality, corrosion-resistant materials (e.g., hot-dip galvanized steel, stainless steel, high-grade plastics) is crucial to ensure a long service life and reduce maintenance costs in harsh farm environments.

These trends collectively push manufacturers to innovate, ensuring that modern farrowing solutions not only meet regulatory requirements but also contribute significantly to the economic viability and ethical standards of swine production.

Manufacturing Process Flow for Advanced Pig Farrowing Pens

The production of durable and efficient pig farrowing pens involves a rigorous multi-stage manufacturing process, ensuring precision, strength, and longevity. Our adherence to international standards like ISO 9001 guarantees product quality from raw material sourcing to final assembly.

Schematic Steps of Manufacturing:

- Material Sourcing and Quality Inspection: High-grade steel (e.g., Q235, Q345 for structural components) and virgin plastics (e.g., polypropylene, PVC for flooring) are procured from certified suppliers. Incoming materials undergo strict chemical composition and mechanical property testing (e.g., tensile strength, yield strength) to meet ISO and ASTM standards.

- Cutting and Shaping: Steel pipes and sheets are precisely cut using CNC laser or plasma cutting machines. Bending and forming operations for specialized components are performed using hydraulic press brakes, ensuring accurate dimensions and minimal material stress.

- Welding and Assembly: Components are assembled using advanced welding techniques (e.g., MIG/MAG welding) by certified welders. Fixtures are utilized to maintain dimensional accuracy throughout the welding process. All welds are visually inspected, and random samples undergo destructive and non-destructive testing (NDT) according to ANSI/AWS D1.1 standards.

- Surface Treatment (Hot-dip Galvanization): Fabricated steel frames are pre-treated (degreasing, pickling, fluxing) and then immersed in molten zinc at approximately 450°C. This hot-dip galvanization process, adhering to ISO 1461/ASTM A123 standards, provides superior corrosion resistance, crucial for the humid and corrosive environment of a pig farm. This treatment significantly extends the service life of the pens, typically to 15-20 years.

- Flooring Production (Injection Molding): Plastic slatted flooring is manufactured via high-pressure injection molding using durable, non-porous polymers. This ensures smooth surfaces for hygiene, optimal gap size for waste removal, and ergonomic design for animal comfort.

- Final Assembly and Quality Control: Galvanized frames, plastic flooring, feeding troughs (stainless steel or cast iron), and watering nipples are assembled. Each pen undergoes a comprehensive final inspection, checking for structural integrity, dimensional accuracy, coating thickness (for galvanization), functionality of moving parts, and overall finish.

- Packaging and Shipment: Pens are carefully packaged to prevent damage during transit, often bundled or palletized for efficient logistics.

The target industries for these robust systems are primarily commercial swine farms, breeding operations, and agricultural research institutions. Advantages in typical application scenarios include enhanced biosecurity due to easy-to-clean surfaces, improved piglet survival rates through precise environmental control and anti-crushing bars, and long-term cost savings due to exceptional corrosion resistance and a service life exceeding 15 years.

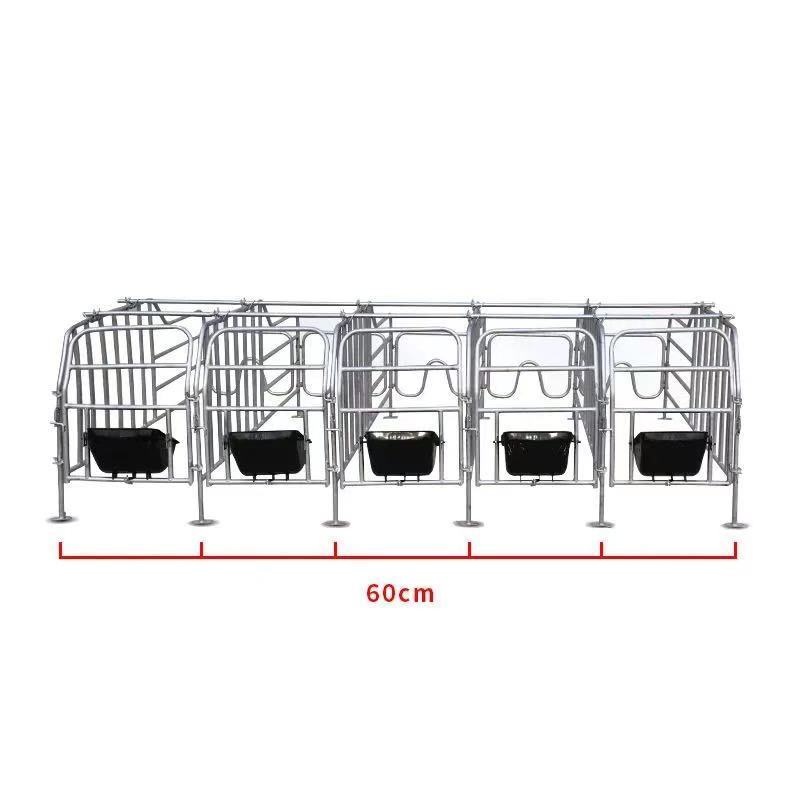

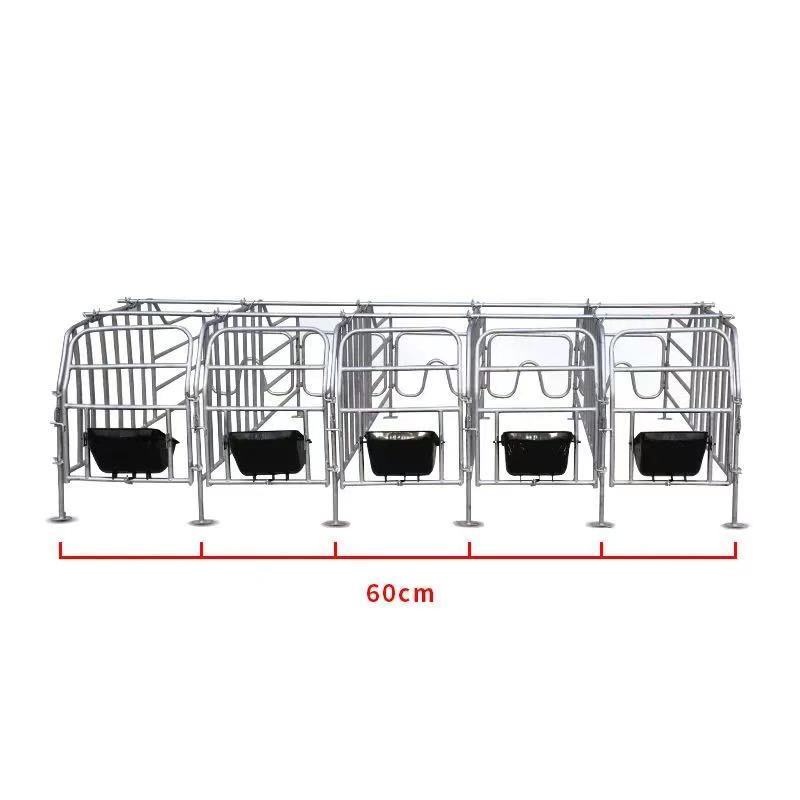

Technical Specifications of Farrowing Pens for Pigs (Sow Gestation Pen Example)

Our Sow Gestation Pen, a prime example of advanced farrowing pens for pigs, is designed with meticulous attention to detail, adhering to stringent engineering specifications to ensure optimal performance, durability, and animal welfare.

Product Specification Table: Sow Gestation Pen

| Parameter | Specification | Details/Benefit |

|---|---|---|

| Model Name | YZM-FarrowGen-P01 | Optimized for standard commercial sow breeds. |

| Overall Dimensions (L x W x H) | 2.4 m x 1.8 m x 1.1 m (approx.) | Standard sizing for efficient space utilization and sow comfort. |

| Frame Material | Q235 Hot-Dip Galvanized Steel | Exceptional corrosion resistance, service life > 15 years. |

| Tube Thickness | 2.2 mm - 2.5 mm | Ensures high structural integrity and resistance to deformation. |

| Flooring System | Cast Iron (sow area) / Plastic Slatted (piglet creep area) | Durable, non-slip, optimal waste removal, thermal comfort for piglets. |

| Anti-Crushing Bars | Adjustable, Hot-Dip Galvanized Steel | Minimizes piglet mortality by preventing crushing, adjustable for sow size. |

| Feeder Type | Stainless Steel Dry Feeder | Corrosion-resistant, hygienic, easy to clean, minimizes feed waste. |

| Drinker System | Nipple Drinker (Sow & Piglet) | Constant fresh water supply, prevents contamination, efficient. |

| Environmental Control (Optional) | Heat Lamp/Pad Mounting Brackets | Allows for localized heating in piglet creep area, crucial for thermoregulation. |

| Weight | Approx. 150-200 kg (varies with configuration) | Robust construction ensures stability and durability. |

| Compliance Standards | ISO 9001, CE Certified | Guarantees quality management and European safety standards compliance. |

These detailed specifications underscore our commitment to delivering superior farrowing equipment that supports efficient and humane swine production practices.

Application Scenarios for Advanced Pig Farrowing Pens

Modern pig farrowing pens are versatile systems essential for various stages of swine production, significantly impacting the health of both sows and piglets, as well as operational efficiency.

Typical Application Environments:

- Commercial Swine Breeding Farms: The primary application, where thousands of sows farrow annually. Our pens facilitate high throughput, minimizing piglet mortality through optimized design and robust construction. The controlled environment supports critical post-farrowing care, ensuring healthy development from day one.

- Research and Development Facilities: Universities and private research centers utilize these pens for studying animal behavior, nutrition, genetics, and disease management in controlled farrowing environments. The precision and adjustability of our pens provide consistent conditions for scientific inquiry.

- Small to Medium-Sized Family Farms: While often associated with large-scale operations, efficient and welfare-focused farrowing solutions are equally crucial for smaller enterprises. Our modular systems can be scaled to fit diverse farm sizes, helping them achieve better productivity and animal welfare standards.

Operational Advantages in Practice:

- Optimized Piglet Survival: Features like anti-crushing bars, heated creep areas, and adjustable sow positions are critical in the first few days of a piglet's life, drastically reducing overlay deaths, which account for a significant portion of pre-weaning mortality.

- Improved Sow Health and Comfort: Ergonomic designs reduce stress during farrowing and lactation. Access to fresh water and feed is optimized, supporting milk production and sow recovery.

- Enhanced Farm Biosecurity: Easy-to-clean materials and designs minimize pathogen accumulation. This contributes significantly to overall herd health, reducing the need for antibiotics and improving food safety.

- Labor Efficiency: Thoughtful design allows for easy access to sows and piglets for inspection, feeding, and medical intervention, reducing labor time and improving worker safety.

Technical Advantages of Our Pigs Pen Systems

Our advanced pigs pen systems, particularly our farrowing solutions, are engineered to deliver superior performance and long-term value through a combination of innovative design, material science, and precision manufacturing.

Key Technical Advantages:

- Superior Material Durability: Utilizing heavy-gauge, hot-dip galvanized steel for structural components ensures exceptional resistance to rust and corrosion, even in the highly acidic and humid conditions of swine housing. This significantly extends the service life, outperforming painted or electro-galvanized alternatives.

- Optimized Flooring Systems: Our pens incorporate a hybrid flooring approach. Cast iron slats in the sow area provide robust support and excellent heat dissipation, while plastic slatted flooring in the piglet creep area offers better thermal insulation and a gentler surface for developing hooves, minimizing lesions. The precise gap design facilitates efficient manure removal, maintaining hygiene.

- Advanced Anti-Crushing Mechanisms: Featuring robust, adjustable anti-crushing bars or "fender bars" that create a protected zone for piglets when the sow lies down. Some designs incorporate pivot mechanisms allowing the sow more freedom while still protecting the piglets, balancing welfare and safety.

- Ergonomic Design for Sow and Piglet Access: Pen doors and side panels are designed for easy and quick access by farm personnel for inspection, feeding, and veterinary care. The layout ensures sows can access feed and water comfortably, promoting good nutrition and milk production. Piglet creep areas are strategically placed and often include supplemental heating.

- Modular and Customizable Construction: The modular design allows for flexible layouts and easy installation, adaptation, or replacement of components. This adaptability means our systems can integrate seamlessly into existing farm infrastructure or new builds, accommodating various herd sizes and management strategies.

- Biosecurity-Friendly Design: All surfaces are smooth, non-porous, and easily washable, minimizing the adherence of pathogens. This facilitates thorough cleaning and disinfection protocols, critical for disease prevention and overall herd health.

These technical advantages translate directly into higher piglet survival rates, reduced labor costs, improved animal health, and a greater return on investment for swine producers.

Vendor Comparison: Evaluating Pig Farrowing Pens Solutions

When selecting pig farrowing pens, B2B decision-makers must consider various factors beyond initial cost. This comparison highlights key differentiators among common types of farrowing solutions available in the market.

Farrowing Pen Solutions Comparison Table:

| Feature/Solution Type | Traditional Farrowing Crates | Freedom Farrowing Systems | Our Advanced Sow Gestation Pen |

|---|---|---|---|

| Sow Mobility | Highly restricted (crate) | Full mobility within a larger pen | Controlled restriction with adjustable anti-crush bars, optional temporary freedom. |

| Piglet Protection | High (sow confined, specific creep area) | Moderate (requires careful management, high risk of crushing) | Very High (robust anti-crushing bars, protected creep zones, optimal flooring) |

| Initial Investment | Low to Moderate | High (larger footprint, more complex design) | Moderate to High (balanced with longevity and ROI) |

| Longevity/Durability | Moderate (often painted steel, susceptible to corrosion) | Varies widely by manufacturer and material | Excellent (>15 years, hot-dip galvanized steel, robust components) |

| Hygiene/Cleanability | Good (compact, but can have hidden areas) | Moderate (larger area, more corners/components) | Excellent (smooth, non-porous surfaces, efficient waste removal) |

| Operational Efficiency | High (easy handling of sows/piglets) | Moderate (more interaction required, higher piglet mortality risk) | Very High (optimal balance of animal welfare and farm management) |

Our advanced Sow Gestation Pen strikes an optimal balance, integrating the proven safety and efficiency of traditional designs with enhanced welfare considerations and superior durability, offering a long-term, high-return solution.

Customized Solutions for Farrowing Pen for Pigs

Recognizing that every swine operation has unique requirements, we offer extensive customization options for our farrowing pen for pigs. Our engineering team collaborates closely with clients to develop bespoke solutions that align with specific farm layouts, herd sizes, environmental conditions, and regulatory compliance needs.

Areas of Customization:

- Dimensions and Configuration: Adjustments to pen length, width, and height to fit existing buildings or accommodate different sow breeds (e.g., larger dimensions for hyper-prolific breeds). Options for linear, back-to-back, or central corridor layouts.

- Flooring Systems: Choice of full plastic, full cast iron, or hybrid combinations, with varying slat widths and gap sizes to optimize for specific climates or waste management strategies. Consideration for heated floor systems in creep areas.

- Feeder and Drinker Integration: Selection of trough materials (stainless steel, polymer), designs (wet/dry feeders, automatic dispensing), and nipple drinker types and positions to suit farm-specific feeding protocols and water supply systems.

- Sow Confinement Mechanisms: While our standard anti-crushing bars are highly effective, we can integrate temporary freedom farrowing elements or specialized gate systems that allow more sow movement during specific periods while maintaining piglet safety.

- Environmental Control Integration: Custom brackets and provisions for heat lamps, heating pads, ventilation ducts, and sensor placements to ensure precise microclimate control within the piglet creep area, crucial for early life thermoregulation.

- Access and Management Features: Design modifications for gate types (swing, lift), locking mechanisms, and additional access points to optimize worker flow, animal handling, and veterinary intervention efficiency.

Our dedicated design and manufacturing capabilities ensure that customized solutions maintain the same high standards of quality, durability, and performance as our standard offerings, delivering optimal results tailored to your specific operational needs.

Application Case Studies: Real-World Success with Pig Farrowing Pens

Our pig farrowing pens have been instrumental in enhancing productivity and welfare across diverse commercial swine operations. Below are illustrative case studies highlighting the tangible benefits achieved by our clients.

Case Study 1: Large-Scale Commercial Farm Modernization

Client: "Agri-Pork Solutions," a commercial farm managing 5,000 sows in the Midwest, USA.

Challenge: Agri-Pork faced high pre-weaning piglet mortality (18%) and increasing maintenance costs for their aging, corroded farrowing crates. Their existing pens were difficult to clean, leading to persistent biosecurity challenges.

Solution: We supplied 500 units of our advanced Sow Gestation Pens, featuring hot-dip galvanized steel frames, hybrid cast iron and plastic flooring, and adjustable anti-crushing bars. The installation was staggered over 12 months to minimize disruption.

Results:

- Pre-weaning mortality reduced from 18% to 12% within the first year, largely due to enhanced piglet protection.

- Cleaning time for farrowing rooms decreased by 25% due to improved flooring and material surfaces, leading to better biosecurity.

- Sow feed intake during lactation increased by an average of 5%, attributed to improved pen comfort and feeder design.

- Expected service life extended by an estimated 8-10 years compared to their previous equipment, reducing long-term capital expenditure.

Customer Feedback: "The investment in these pens paid off quicker than we anticipated. The reduction in piglet losses alone has significantly boosted our profitability, and the robust construction means we won't be replacing them for a very long time." - John M., Operations Manager, Agri-Pork Solutions.

Case Study 2: Research Facility Upgrade for Animal Welfare Studies

Client: "Mid-Atlantic Animal Science Research Institute," an academic institution focused on sustainable livestock practices.

Challenge: The Institute required highly adaptable farrowing pens for studies on varying levels of sow mobility and piglet survival under different conditions, necessitating precision control and modularity.

Solution: We provided customized farrowing pens with reconfigurable partitions, dual-zone flooring (heating options), and integrated sensor mounts for environmental monitoring. The modular design allowed researchers to easily reconfigure pens for different experimental setups.

Results:

- Enhanced data collection accuracy due to consistent and controllable pen environments.

- Flexibility to conduct a wider range of animal welfare studies without extensive facility modifications.

- Durability proved essential for repeated disinfection and component changes between research trials.

Customer Feedback: "The customizable pens from [Our Company Name] have been invaluable to our research. Their robust construction and adaptable design mean we can reliably test various farrowing systems, providing critical data for the industry." - Dr. Emily R., Lead Researcher, MASRI.

Frequently Asked Questions (FAQ) about Farrowing Pens for Pigs

Q1: What is the typical lifespan of your farrowing pens?

A1: Our hot-dip galvanized steel frames are engineered for exceptional longevity, typically providing a service life of 15 to 20 years under proper usage and maintenance. Plastic components are designed for similar durability, with an expected lifespan of 10-15 years before potential replacement.

Q2: Are your farrowing pens compliant with animal welfare standards?

A2: Yes, our pens are designed with a strong emphasis on animal welfare. They incorporate features like adjustable anti-crushing bars, comfortable flooring options, and accessible feeding/watering systems that meet or exceed common industry welfare guidelines. We also offer customization to align with specific regional regulations or voluntary certification programs.

Q3: What is the lead time for an order of farrowing pens?

A3: Standard orders typically have a lead time of 4-6 weeks from order confirmation to shipment, depending on the quantity and current production schedule. Customized solutions may require an additional 2-3 weeks for design finalization and specialized manufacturing. We recommend contacting our sales team for precise lead time estimates for your specific order.

Q4: Do you offer installation services or guidance?

A4: While our pens are designed for straightforward assembly, we provide comprehensive installation manuals and remote technical support. For large-scale projects, we can arrange for on-site supervision or training by our experienced technicians.

Q5: What kind of warranty do you provide?

A5: We offer a 5-year limited warranty on structural steel components (frame, gates) against manufacturing defects and excessive corrosion under normal usage conditions. Other components, such as plastic flooring and feeders, carry a 1-year warranty. Full warranty details are provided with each purchase agreement.

Q6: How do I get after-sales support?

A6: Our dedicated customer support team is available via phone and email during business hours to assist with any technical queries, parts orders, or service requests. We pride ourselves on responsive and effective after-sales service to ensure the smooth operation of your farm.

Authoritative References and Standards

Our commitment to quality and industry best practices is underscored by adherence to international standards and consultation of leading research in animal science and agricultural engineering.

- ISO 9001:2015 - Quality management systems. International Organization for Standardization.

- ISO 1461:2009 - Hot dip galvanized coatings on fabricated iron and steel articles. Specifications and test methods. International Organization for Standardization.

- ASTM A123/A123M-17 - Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- ANSI/AWS D1.1/D1.1M:2020 - Structural Welding Code – Steel. American Welding Society.

- The Welfare of Pigs, Scientific Report of the European Food Safety Authority (EFSA), 2007.

- Journal of Animal Science, various articles on swine farrowing systems and piglet mortality rates.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025