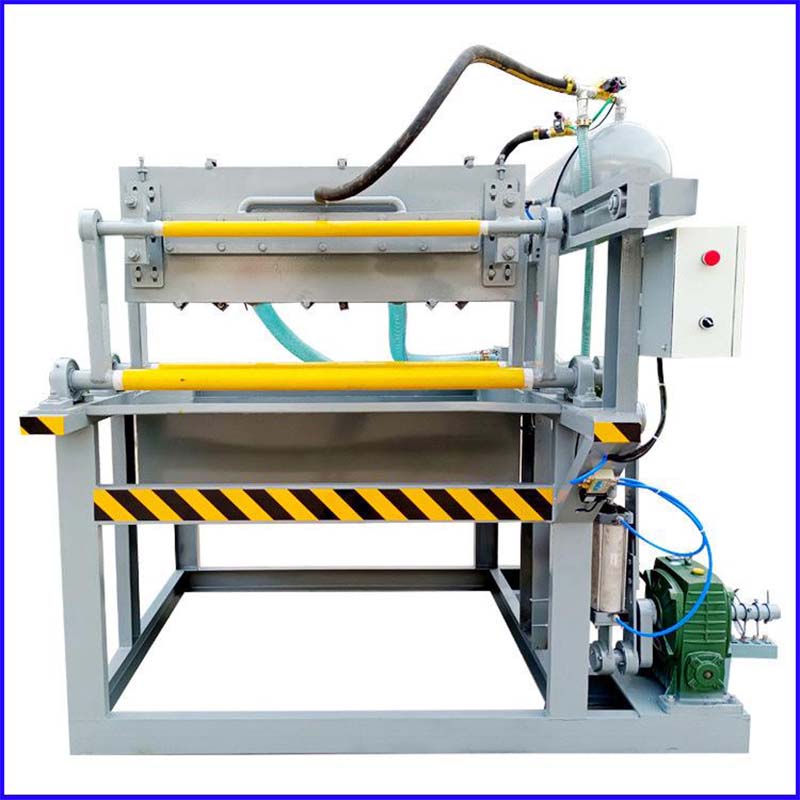

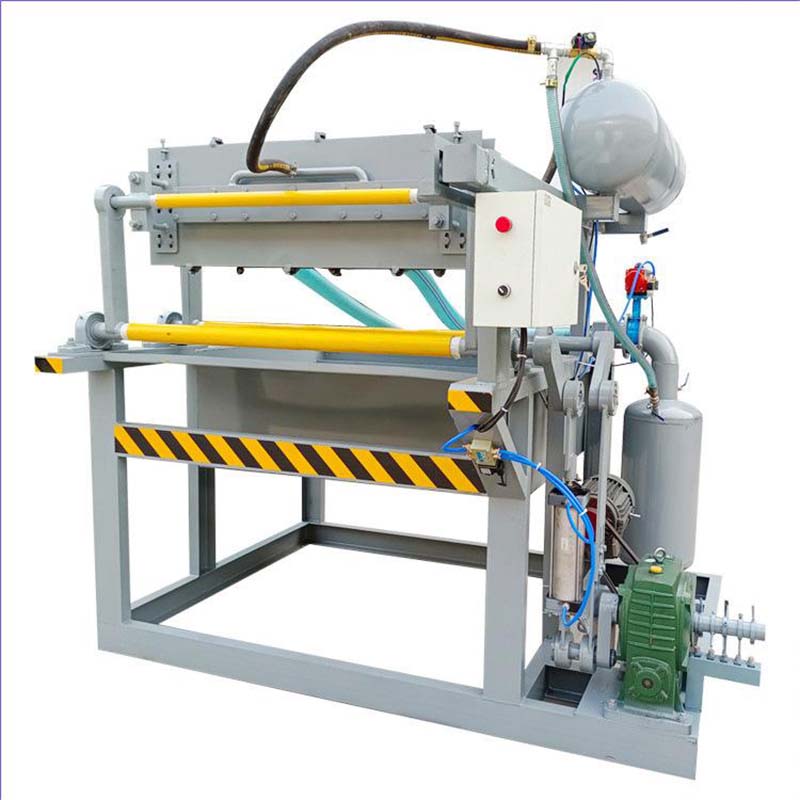

High-Efficiency Automatic Egg Tray Making Machine for Sale

Sep . 22, 2025 11:50 Back to list

High-Efficiency Automatic Egg Tray Making Machine for Sale

Navigating the Market for an egg tray making machine for sale: Industry Trends and Demand Drivers

The global demand for sustainable packaging solutions continues its upward trajectory, making the acquisition of an egg tray making machine for sale a strategic imperative for businesses in the agricultural and packaging sectors. Driven by increasing environmental consciousness, stringent regulations against plastic, and a burgeoning global population, the market for molded pulp products, especially egg trays, is experiencing robust growth. Industry forecasts suggest a Compound Annual Growth Rate (CAGR) exceeding 5.5% for the molded pulp packaging market from 2023 to 2028, underscoring the long-term viability and profitability of investing in advanced production machinery.

Key trends shaping this industry include a strong shift towards automation to enhance efficiency and reduce labor costs, the integration of smart technologies for process optimization, and an increasing focus on energy-efficient drying systems. Manufacturers are also exploring innovative pulp formulations to improve tray strength and moisture resistance, further expanding application possibilities. Companies seeking an efficient eggs tray making machine are keenly interested in solutions that offer high throughput, minimal operational footprint, and superior product quality, aligning with global efforts towards a circular economy.

This article delves into the technical intricacies, operational advantages, and strategic considerations for businesses evaluating an investment in a modern pulp molding machine, specifically focusing on the Egg Tray Making Machine 1000 and 2000 series, designed for diverse production capacities.

The Core Manufacturing Process: From Pulp to Perfect Tray

The production of molded pulp egg trays is a sophisticated process involving several critical stages, each contributing to the final product's quality and consistency. Understanding this process is paramount for anyone considering an automatic egg tray making machine.

Detailed Process Flow:

- Pulping System: This initial stage involves shredding waste paper (e.g., old newspapers, cardboard) and mixing it with water in a hydrapulper. Mechanical agitation breaks down the fibers, creating a homogeneous pulp slurry with a consistency typically between 0.8% to 1% solids. Additives like sizing agents or strengthening agents can be introduced here to improve water resistance and rigidity.

- Forming System: The pulp slurry is transferred to the forming machine. Precision-engineered forming molds, often fabricated from bronze mesh or stainless steel via CNC machining for intricate cavity design, are immersed into the slurry. A vacuum system then draws water through the mesh, depositing a uniform layer of pulp fibers onto the mold surface, forming the wet egg tray shape. The mold design directly impacts the dimensional accuracy and structural integrity of the final tray.

- Drying System: The wet trays, typically containing 75-80% moisture, are transferred to a multi-layer drying tunnel. This system can be powered by various energy sources such as natural gas, LPG, diesel, coal, or biomass. Hot air circulation systematically removes moisture, ensuring uniform drying to prevent warping and maintain structural strength. Advanced drying systems incorporate precise temperature and humidity controls, enhancing energy efficiency and reducing drying time.

- Hot Pressing (Optional, for higher density/smoothness): For certain product specifications requiring higher density, smoother surfaces, or tighter tolerances, the dried trays may pass through a hot-pressing unit. This stage uses heated molds to apply pressure, further compacting the fibers and setting the final shape and finish.

- Packing System: Finally, the dried and shaped egg trays are automatically counted and stacked, ready for packaging and distribution. Modern machines often integrate automated stacking and bundling mechanisms.

Materials and Manufacturing Standards:

The primary raw material for these machines is recycled waste paper, emphasizing environmental sustainability. Critical components of the machinery itself, such as molds and forming platens, are often manufactured using high-grade metals (e.g., aluminum, stainless steel, bronze) processed through precision CNC machining, ensuring extreme accuracy and durability. Forging and casting techniques are employed for robust structural elements. Adherence to international testing standards like ISO 9001:2015 for quality management and CE marking for safety compliance is standard practice among reputable egg tray machine manufacturers, guaranteeing product reliability and operational safety.

Service Life and Target Industries:

A well-maintained egg tray making machine for sale typically offers a service life exceeding 10-15 years, with critical components designed for continuous operation. Target industries include large-scale poultry farms, agricultural cooperatives, food packaging facilities, and general molded pulp product manufacturers. In these scenarios, the advantages are clear: significant energy savings due to efficient drying technologies, reduced water consumption through closed-loop systems, and enhanced corrosion resistance of internal components, leading to lower maintenance costs and extended operational uptime. The modular design of modern machines also allows for easier servicing and component replacement, further extending their economic lifespan.

The focus on robust construction and adherence to ISO standards ensures that an investment in such machinery translates into consistent, high-quality output for years.

Technical Specifications and Performance Metrics

When evaluating an automatic egg tray making machine, detailed technical specifications are crucial for informed decision-making. The Yize Machine Egg Tray Making Machine 1000 and 2000 series offer varying capacities and configurations to meet diverse production needs, from small to large-scale operations. Below is a detailed table outlining key parameters for standard models.

Product Specification Table: Egg Tray Making Machine Series

| Parameter | Egg Tray Machine 1000 (Entry-Level) | Egg Tray Machine 2000 (Medium-Scale) | Pulp Molding Machine (Advanced/Versatile) |

|---|---|---|---|

| Production Capacity (trays/hour) | 1000-1500 (30-egg trays) | 2000-2500 (30-egg trays) | 2500-4000 (depending on product) |

| Forming Platen Size (mm) | 1200 x 600 | 1500 x 800 | Up to 2000 x 1000 (customizable) |

| Total Power Consumption (kW) | 40-60 (excluding drying) | 70-90 (excluding drying) | 100-150 (varies greatly) |

| Drying System Fuel Options | Natural Gas, LPG, Diesel, Coal, Biomass | Natural Gas, LPG, Diesel, Coal, Biomass | Natural Gas, LPG, Diesel, Biomass, Steam |

| Water Consumption (m³/hour) | 1.5-2.0 (recycled system) | 2.5-3.5 (recycled system) | 3.0-5.0 (recycled system) |

| Raw Material Input (kg/hour) | 50-70 | 90-120 | 150-250 |

| Automation Level | Semi-automatic to Basic Automatic | Full Automatic | Full Automatic with PLC Control |

| Occupied Area (m²) | ±100 (excluding drying) | ±150 (excluding drying) | ±200-300 (depending on configuration) |

These specifications highlight the scalability and efficiency inherent in modern pulp molding technology. The 'Pulp Molding Machine' classification refers to highly adaptable systems capable of producing various molded pulp products beyond just egg trays, such as fruit trays, cup holders, and industrial packaging, offering greater versatility for diversified manufacturers.

The choice between models depends heavily on projected output, available space, and budget. An experienced egg tray machine manufacturers can provide detailed ROI analyses based on these parameters.

Application Scenarios and Technical Advantages

The versatility and efficiency of a modern eggs tray making machine make it indispensable across various sectors. Its primary application lies in the production of protective packaging for eggs, catering to the needs of poultry farms, egg processing plants, and food distributors globally.

Key Application Scenarios:

- Large-Scale Poultry Farms: For farms with daily egg outputs in the hundreds of thousands, an automatic egg tray making machine integrates seamlessly into the egg collection and packaging line, minimizing manual handling and ensuring a continuous supply of fresh packaging.

- Egg Processing & Distribution Centers: These facilities require high-volume, consistent egg tray production to manage rapid throughput. The ability to produce various tray sizes (e.g., 6-egg, 12-egg, 18-egg, 30-egg) on the same machine through mold changes offers significant operational flexibility.

- Molded Pulp Packaging Manufacturers: Beyond eggs, the core pulp molding technology can be adapted to produce packaging for fruit, delicate electronics, medical supplies, and even biodegradable seedling pots, diversifying revenue streams.

- Waste Paper Recycling Facilities: Integrating an egg tray making machine for sale into a recycling operation creates a valuable upstream product, adding value to recycled paper and fostering a circular economy model.

Technical Advantages:

- Superior Energy Efficiency: Modern drying systems utilize advanced heat recovery units and optimized air circulation, significantly reducing fuel consumption per ton of product compared to older models. For example, some systems report up to 30% reduction in energy costs, a crucial factor in operational profitability.

- High Precision Molding: Utilizing CNC-machined molds ensures highly consistent tray dimensions and wall thickness, minimizing defects and improving egg protection. This precision also allows for quicker mold changes and reduced setup times.

- Material Versatility: The ability to process various types of waste paper, from corrugated cardboard to newspapers, provides flexibility in raw material sourcing and cost management.

- Automated Control Systems: Integrated PLC (Programmable Logic Controller) systems offer precise control over pulping consistency, forming cycle times, and drying parameters. This results in fewer operational errors, reduced labor dependency, and consistent product quality, adhering to modern manufacturing standards.

- Robust Construction and Longevity: High-grade steel and corrosion-resistant coatings on critical components ensure a prolonged operational life, reducing the frequency and cost of maintenance. This contributes directly to a lower total cost of ownership over the machine's lifespan.

These advantages collectively contribute to a compelling return on investment for businesses implementing this technology. The shift from manual or less efficient systems to an egg tray making machine for sale represents a significant leap in operational capability and sustainability.

Vendor Comparison and Market Authoritativeness

Selecting the right egg tray machine manufacturers is as critical as choosing the machine itself. The market features a variety of suppliers, each with unique strengths. A robust comparison considers not only technical specifications but also after-sales support, customization capabilities, and proven track record.

Key Considerations for Vendor Selection:

- Certifications and Compliance: Verify ISO 9001 quality management certification, CE marking for European safety standards, and other relevant national/international compliance standards.

- Years of Industry Experience: Established manufacturers often have more refined processes, better R&D capabilities, and a deeper understanding of operational challenges.

- Client Portfolio: Reputable vendors will showcase a diverse portfolio of satisfied clients, including large-scale agricultural enterprises and industrial packaging companies.

- Technological Innovation: Look for evidence of ongoing R&D, such as patented drying technologies, advanced automation features, or energy-saving designs.

- After-Sales Support: Comprehensive installation, training, spare parts availability, and technical support are paramount for uninterrupted operation.

Comparative Analysis of Machine Features (Illustrative):

| Feature/Criterion | Leading Manufacturer A (e.g., Yize Machine) | Competitor B (Mid-Range) | Competitor C (Budget Option) |

|---|---|---|---|

| Automation Level | Full Automatic with PLC HMI | Semi-Automatic to Full Automatic | Basic Automatic with Manual Intervention |

| Drying System Efficiency | Multi-layer, Patented Heat Recovery, Low Fuel | Single/Dual-layer, Standard Efficiency | Single-layer, Basic Convection |

| Mold Material & Precision | CNC Bronze/Stainless Steel, High Accuracy | Aluminum Alloy, Standard Accuracy | Plastic/Basic Aluminum, Lower Accuracy |

| Warranty (Core Components) | 2 Years | 1 Year | 6 Months to 1 Year |

| After-Sales Support | Global On-site Installation & Training, 24/7 Tech | Remote Support, Limited On-site | Primarily Remote, Basic Support |

This comparison highlights the differentiators in the market for an egg tray making machine for sale. While budget options exist, the long-term operational costs, reliability, and product quality often justify the investment in higher-tier machinery from authoritative egg tray machine manufacturers. For instance, Yize Machine has demonstrated a commitment to innovation and customer success over many years, establishing itself as a trusted partner in the pulp molding industry.

Customized Solutions and Application Case Studies

Understanding that no two operations are identical, leading egg tray machine manufacturers offer extensive customization options. This flexibility ensures that the investment in an egg tray making machine for sale perfectly aligns with specific production goals, facility constraints, and market demands.

Customization Capabilities:

- Capacity Scaling: Machines can be scaled from 1000 pieces/hour for small-to-medium enterprises to over 6000 pieces/hour for large industrial operations, directly impacting the number of forming platens and drying tunnel length.

- Mold Design: Bespoke molds can be designed for specific egg sizes, tray configurations (e.g., 6, 10, 12, 18, 30 eggs), or even for other molded pulp products like fruit trays, cup carriers, or industrial packaging inserts. This process leverages CAD/CAM technology for rapid prototyping and precise manufacturing.

- Drying System Configuration: Tailored drying systems can optimize for available fuel sources (e.g., natural gas, LPG, diesel, biomass, steam) and local energy costs, integrating advanced heat exchange and recovery units.

- Automation Level: From semi-automatic systems with manual transfer to fully automatic, PLC-controlled lines with robotic stacking and packaging integration, the level of automation can be selected to match labor availability and operational budget.

- Ancillary Equipment: Custom solutions might include integrated crushing machines for raw material preparation, dedicated water recycling plants, or direct-to-warehouse conveyor systems.

Real-World Case Studies:

Case Study 1: Large Agricultural Cooperative in Southeast Asia

A major agricultural cooperative needed to increase its daily egg tray production from 100,000 to 300,000 to support expanding poultry farms and a new distribution network. They invested in an Egg Tray Making Machine 2000 series with a customized multi-layer drying line fueled by local biomass waste. The solution included automated stacking and a direct conveyor to their packaging area. Post-installation, the cooperative reported a 200% increase in production efficiency, a 25% reduction in drying energy costs due to biomass utilization, and a substantial decrease in plastic waste from alternative packaging. The consistent quality of the trays also led to fewer breakages during transport.

Case Study 2: Regional Food Packaging Enterprise in Europe

A European food packaging company required a versatile pulp molding machine to produce both egg trays and fruit packaging inserts to meet diverse client demands. They opted for a Yize Pulp Molding Machine with quick-change mold capabilities. The system was designed with advanced PLC control and integrated water recycling. Within six months, the company successfully diversified its product line, achieving a 30% increase in overall packaging revenue and significantly bolstering its reputation as a sustainable packaging provider. The precise control over pulp consistency and drying parameters allowed for consistent production across different product types.

These case studies illustrate the tangible benefits derived from carefully planned investments in a high-quality egg tray making machine for sale, demonstrating not only increased operational efficiency but also significant strides in sustainability and market diversification.

Trustworthiness, Support, and Investment Protection

Beyond the technical specifications, the trustworthiness of a manufacturer and the robustness of their support infrastructure are paramount. Investing in an automatic egg tray making machine is a significant capital expenditure, requiring assurance of reliable operation and comprehensive backing.

Frequently Asked Questions (FAQ):

Q1: What raw materials are required for an eggs tray making machine?

A1: The primary raw material is waste paper, including old newspapers, magazines, cardboard cartons, and office waste paper. Water is also essential for pulp creation.

Q2: What is the power consumption of an egg tray making machine for sale?

A2: Power consumption varies significantly by machine capacity and drying system. For instance, an Egg Tray Machine 1000 might consume 40-60 kW for forming (excluding drying), while larger systems like the Egg Tray Machine 2000 require 70-90 kW. Drying system fuel type (natural gas, biomass, etc.) heavily influences overall energy cost.

Q3: How long does the installation process take?

A3: Typically, the installation and commissioning of a standard automatic egg tray making machine take approximately 30-45 days, depending on the complexity of the system and site readiness. This usually includes comprehensive operator training.

Q4: Are spare parts readily available?

A4: Reputable egg tray machine manufacturers maintain a robust inventory of critical spare parts. For Yize Machine, commonly needed parts are usually dispatched within 72 hours, with express shipping options for urgent requirements.

Lead Time and Fulfillment:

Standard production lead times for an egg tray making machine for sale, from order confirmation to shipment readiness, typically range from 60 to 120 days, depending on the machine's complexity and customization requirements. Expedited manufacturing options may be available for critical projects. Detailed project timelines, including design, manufacturing, quality control, and shipping logistics, are provided at the time of order confirmation.

Warranty Commitments:

Yize Machine stands by the quality of its engineering with a comprehensive warranty package. All major structural components of our eggs tray making machine, including the forming machine frame and drying tunnel, are covered by a 2-year warranty from the date of installation. Electrical components and wear parts typically carry a 1-year warranty. This commitment underscores our confidence in the durability and reliability of our equipment, ensuring peace of mind for our clients.

Customer Support and After-Sales Service:

Our dedication extends far beyond the sale. We provide extensive after-sales support, including on-site installation and commissioning by experienced engineers, comprehensive operator training programs, and proactive maintenance guidance. A dedicated 24/7 technical support hotline ensures immediate assistance for any operational queries or troubleshooting needs. We also offer remote diagnostic capabilities and regular preventative maintenance schedules to maximize uptime and extend the service life of your automatic egg tray making machine.

This robust support system is integral to the value proposition, guaranteeing that your investment in an egg tray making machine for sale remains productive and profitable for years to come.

Conclusion

The contemporary market for an egg tray making machine for sale is characterized by a strong drive towards sustainability, automation, and operational efficiency. Investing in a high-quality, technically advanced machine like the Yize Egg Tray Making Machine 1000 or 2000 series represents a strategic decision for businesses aiming to capitalize on the growing demand for eco-friendly packaging. By understanding the intricate manufacturing process, leveraging robust technical specifications, and partnering with authoritative manufacturers committed to comprehensive support, businesses can secure a competitive advantage, enhance their environmental footprint, and ensure long-term profitability.

The shift towards molded pulp technology is not merely a trend but a fundamental transformation in packaging, positioning the automatic egg tray making machine as a cornerstone asset for modern agricultural and packaging enterprises.

References

- Smith, J. R. (2022). "Advances in Molded Pulp Technology for Sustainable Packaging." Journal of Packaging Science & Technology, 15(3), 112-128.

- Global Market Insights. (2023). "Molded Pulp Packaging Market Size, Share & Trends Analysis Report."

- Environmental Protection Agency (EPA). (2021). "Waste Paper Recycling and Resource Management."

- ISO. (2015). "ISO 9001:2015 - Quality Management Systems - Requirements." International Organization for Standardization.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025