Efficient Greenhouse Evaporative Cooling Pads: Durable & Effective

Aug . 15, 2025 01:00 Back to list

Efficient Greenhouse Evaporative Cooling Pads: Durable & Effective

Optimizing Horticultural Environments with Advanced Evaporative Cooling Solutions

In modern agriculture, particularly in controlled environment agriculture (CEA) and greenhouse operations, maintaining optimal climatic conditions is paramount for crop yield and quality. High temperatures, especially during peak summer months, can significantly stress plants, leading to reduced growth, disease susceptibility, and even crop failure. This challenge necessitates robust and efficient cooling solutions. Among the most effective and energy-efficient technologies available, greenhouse evaporative cooling pads stand out as a cornerstone technology. These systems leverage the natural process of evaporation to cool air, offering a sustainable and cost-effective method to regulate internal temperatures. They are critical for creating an ideal microclimate, ensuring consistent performance for various plant species, and enhancing overall operational efficiency for growers worldwide.

The demand for precise climate control extends beyond horticulture to various industrial and agricultural sectors. The principles behind an evaporative cooling pad for greenhouse applications are broadly transferable, finding utility in areas like poultry farming, industrial ventilation, and even some commercial spaces requiring high volumes of cooled air. As global temperatures rise and the need for resource-efficient solutions intensifies, the role of advanced evaporative cooling technologies becomes increasingly vital. This article will delve into the technical intricacies, manufacturing excellence, application diversity, and tangible benefits associated with these essential cooling components, providing a comprehensive guide for B2B decision-makers.

Precision Manufacturing of Evaporative Cooling Pads: A Detailed Process

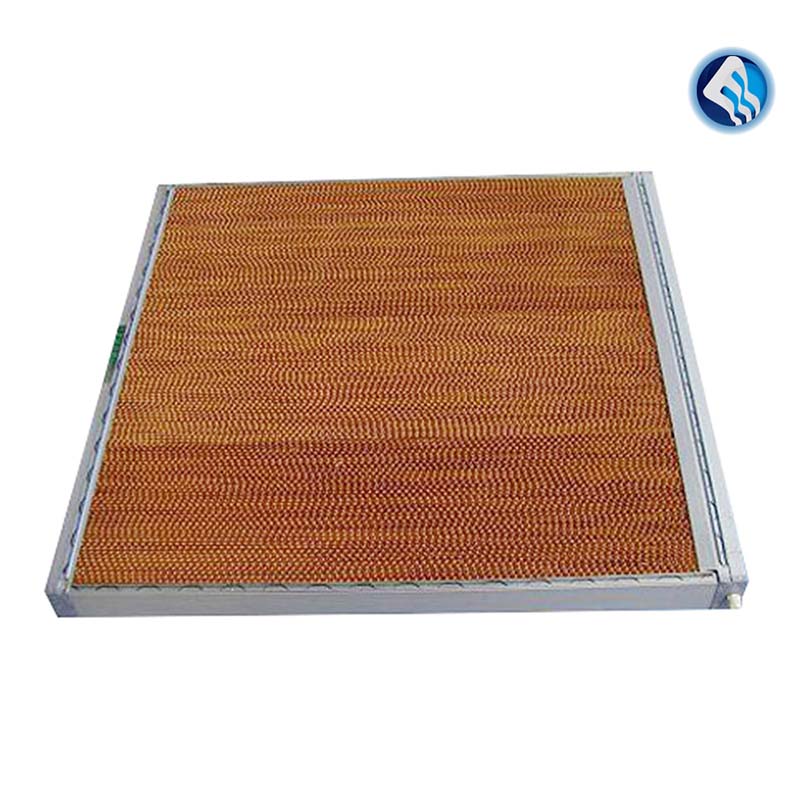

The performance and longevity of greenhouse evaporative cooling pads are intrinsically linked to their manufacturing process and the quality of raw materials used. Our production begins with the selection of high-grade, virgin cellulose paper, typically sourced from renewable forests. This paper undergoes a proprietary treatment process to enhance its structural integrity and water absorption capabilities. The core manufacturing involves corrugating and bonding these cellulose sheets. Precision machinery ensures uniform flute angles and glue lines, crucial for maximizing surface area for evaporation while maintaining structural rigidity. The specific angle of these flutes, often 45/45 or 30/30 degrees, is engineered to optimize airflow and water distribution, leading to superior cooling efficiency.

Following the corrugation and bonding, the pads are impregnated with special resins. These resins provide critical properties such as stiffness, wet strength, and resistance to degradation from water, bacteria, and algae. The impregnation process ensures that the pad maintains its shape and evaporative capacity over an extended lifespan, typically ranging from 5 to 7 years under proper maintenance. Quality control is rigorous at every stage, from raw material inspection to final product testing. Adherence to international standards like ISO 9001 for quality management systems is non-negotiable, ensuring each air cooler evaporative cooling pad meets stringent performance criteria. Tests include evaluating wet strength, saturation efficiency, pressure drop, and resistance to sagging, guaranteeing reliable operation in demanding agricultural and industrial environments.

Technical Specifications and Performance Metrics

Understanding the technical parameters of greenhouse evaporative cooling pads is crucial for system design and performance optimization. Key metrics include saturation efficiency, pressure drop, and structural dimensions. Saturation efficiency, often expressed as a percentage, indicates how close the exiting air temperature gets to the wet-bulb temperature of the incoming air. High-quality pads typically achieve saturation efficiencies of 80% to 95%, making them highly effective in hot, dry climates. Pressure drop, conversely, measures the resistance to airflow through the pad, which directly impacts fan energy consumption. Minimizing pressure drop while maximizing cooling is a critical design objective for manufacturers.

Our evaporative cooling pad water air cooler products are available in various standard dimensions and can be customized to meet specific project requirements. Below is a table detailing typical specifications for our cooling pads, demonstrating the balance between robust performance and operational efficiency. These specifications are a result of extensive R&D and field testing, ensuring reliability and cost-effectiveness for our clients.

| Parameter | Typical Range / Value | Notes |

|---|---|---|

| Material | High-grade Cellulose Paper, Resin Treated | Durable, anti-corrosion, anti-algae |

| Pad Thickness | 100mm, 150mm, 200mm (4, 6, 8 inches) | Thicker pads offer higher efficiency |

| Flute Angle | 45/45 or 30/30 degrees | Optimized for airflow & water distribution |

| Saturation Efficiency | 80% - 95% (depending on thickness) | Higher efficiency in drier climates |

| Pressure Drop | < 25 Pa (for 150mm at 1.5 m/s) | Minimizes fan energy consumption |

| Water Consumption | Approx. 0.06 - 0.1 L/h/m² | Efficient water usage compared to misters |

| Service Life | 5 - 7 years | With proper maintenance and water quality |

Diverse Applications and Key Advantages

The versatility of greenhouse evaporative cooling pads extends across a myriad of sectors requiring controlled thermal environments. In agriculture, beyond traditional greenhouses for vegetables and flowers, these pads are indispensable for mushroom cultivation, livestock facilities, and especially for poultry houses, where maintaining a precise temperature range is critical for animal health and productivity. The term evaporative cooling pads for poultry specifically highlights their significant role in mitigating heat stress in broiler and layer operations, leading to improved feed conversion ratios and reduced mortality rates. Their application also spans into industrial and commercial settings, serving as an efficient and low-cost solution for factory ventilation, data centers, and even large warehouses.

The technical advantages offered by these pads are substantial. Firstly, energy efficiency: evaporative cooling consumes significantly less electricity compared to traditional compressor-based air conditioning systems, often reducing energy costs by 75% or more, making them a sustainable choice. Secondly, environmental benefits: they use water as a refrigerant, which is a natural and environmentally friendly medium, contributing to a lower carbon footprint. Thirdly, improved air quality: the pads filter incoming air, removing dust, pollen, and other airborne particles, contributing to a healthier growing environment or workspace. Their robust design, resistance to biological growth, and ease of maintenance further solidify their position as a preferred cooling solution for demanding B2B applications, ensuring long-term operational savings and performance reliability.

Industry Trends, Manufacturer Comparison, and Custom Solutions

The market for greenhouse evaporative cooling pads is experiencing consistent growth, driven by increasing adoption of CEA, advancements in smart farming, and a global push for sustainable energy solutions. Current trends include the development of pads with enhanced anti-bacterial and anti-algae coatings, further improving hygiene and extending product life. There's also a growing demand for customized solutions that integrate seamlessly with advanced climate control systems and IoT platforms, allowing for precise environmental modulation and remote monitoring. As manufacturers, our commitment to innovation ensures we stay at the forefront of these advancements, offering products that not only meet but exceed industry expectations.

When comparing manufacturers, it's crucial to look beyond initial cost and consider factors like material quality, resin impregnation techniques, manufacturing tolerances, and after-sales support. Some manufacturers might offer lower-cost evaporative cooling filter pads, but these often compromise on density, wet strength, or chemical resistance, leading to shorter lifespans and higher operational costs in the long run. Our company, with over 15 years of experience in the industry, prioritizes long-term value. We specialize in providing bespoke solutions, working closely with clients to design cooling pad systems tailored to their specific greenhouse dimensions, climate conditions, and crop requirements. This consultative approach, combined with our rigorous quality control processes, sets us apart as a trusted partner in climate control technology.

Real-World Application Cases and Client Success Stories

Our greenhouse evaporative cooling pads have been successfully deployed in diverse projects globally, showcasing their efficacy and reliability. For instance, a large-scale tomato greenhouse operation in the arid Middle East utilized our 150mm thick cooling pads to consistently maintain internal temperatures between 22-28°C, even when ambient temperatures soared above 45°C. This resulted in a 30% increase in yield consistency and a significant reduction in plant stress, exceeding the client's initial expectations for productivity and energy savings. Another notable case involves a poultry farm in Southeast Asia, which installed our specialized poultry cooling cell pad system. During peak summer, the system effectively reduced house temperatures by an average of 10°C, leading to a 15% improvement in feed conversion ratio and a dramatic decrease in heat-related mortality among the flock.

These examples underscore our proven track record and the tangible benefits our evaporative cooling solutions deliver. We don't just supply products; we partner with our clients to engineer optimal climate control solutions, providing comprehensive support from initial consultation and system design to installation guidance and after-sales service. Our commitment to client success is reflected in repeat business and strong testimonials from a global network of growers and industrial operators who trust our expertise and the robust performance of our greenhouse evaporative cooling pads. Our ISO 9001 certification further assures our dedication to delivering consistent quality and high-performance solutions.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of your greenhouse evaporative cooling pads?

A: With proper maintenance, water quality, and environmental conditions, our pads are designed for a service life of 5 to 7 years. Our resin treatment significantly enhances their durability against decay and deformation. - Q: How do your cooling pads contribute to energy savings?

A: Evaporative cooling consumes substantially less electricity than compressor-based air conditioning. By using the natural process of water evaporation, our pads can reduce energy consumption for cooling by up to 75% or more, resulting in significant operational cost reductions. - Q: Are your evaporative cooling pads suitable for poultry houses?

A: Absolutely. Our specialized evaporative cooling pads for poultry are specifically engineered to provide optimal cooling and humidity control in poultry environments, effectively reducing heat stress and improving animal welfare and productivity. - Q: What maintenance is required for the cooling pads?

A: Regular cleaning to prevent mineral buildup and algae growth, along with ensuring proper water circulation and quality, is crucial. We provide detailed maintenance guidelines with every purchase to maximize pad longevity and efficiency. - Q: Can these pads be customized for specific dimensions?

A: Yes, we offer extensive customization options for dimensions, thickness, and even specific resin treatments to perfectly fit your unique greenhouse, industrial, or agricultural cooling system requirements.

Delivery Timelines, Quality Assurance, and Customer Support

We understand the critical nature of timely delivery for large-scale B2B projects. Our streamlined manufacturing process and robust supply chain enable us to offer competitive delivery timelines, typically ranging from 3 to 6 weeks depending on order volume and customization requirements. For urgent projects, expedited options can be discussed. Each batch of greenhouse evaporative cooling pads undergoes stringent quality assurance protocols, including material integrity checks, dimensional accuracy verification, and performance testing before dispatch, ensuring that every product meets our high standards and industry specifications. Our commitment to excellence is reinforced by a comprehensive warranty program that covers manufacturing defects for a specified period, giving our clients peace of mind.

Beyond the product, our dedicated customer support team provides unparalleled service. From initial consultation and technical guidance for system design to post-installation support and troubleshooting, our experts are available to ensure optimal performance of your evaporative cooling system. We believe in building lasting partnerships, providing continuous value, and adapting to the evolving needs of our clients in the agricultural and industrial sectors. Your success is our priority, and our long-standing reputation is built on delivering reliable, high-performance cooling solutions backed by expert support.

Conclusion

Greenhouse evaporative cooling pads are more than just a component; they are a vital investment in the productivity, sustainability, and profitability of modern agricultural and industrial operations. By offering superior cooling efficiency, significant energy savings, and environmental benefits, they present a compelling solution for climate control challenges. Our commitment to advanced manufacturing processes, stringent quality control, and unparalleled customer support ensures that our products, including the Evaporative cooling pad water air cooler / poultry cooling cell pad, deliver consistent, reliable performance. Partner with us to achieve optimal environmental control and drive your operational success with cutting-edge evaporative cooling technology.

References

- American Society of Agricultural and Biological Engineers (ASABE) Standards for Environmental Control.

- Journal of Controlled Environment Agriculture Research.

- International Organization for Standardization (ISO) 9001:2015 Guidelines.

- U.S. Department of Energy (DOE) publications on Evaporative Cooling Technologies.

- Agricultural Engineering International: The CIGR Journal.

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025

-

What is a Silo Automatico? Industry Applications, Benefits & Future Trends

NewsNov.20,2025

-

Practical Guide to Egg Laying Chicken Cages for Sale – Durable, Scalable & Sustainable

NewsNov.19,2025