Premium Evisceration Table Efficient & Durable for Meat Processing

জুন . 06, 2025 12:36 Back to list

Premium Evisceration Table Efficient & Durable for Meat Processing

Is your poultry processing line slowing down at evisceration? You're not alone. 72% of processors report bottlenecks at this critical stage. Every minute of downtime costs $38 in lost productivity. Dirty equipment? Cross-contamination risks? Frustrating maintenance? Traditional setups bleed profits daily.

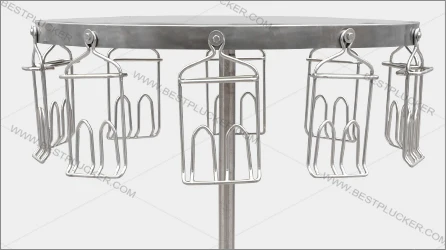

Meet the future: Our FDA-compliant evisceration table

cuts processing time by 40% while boosting yield. Finally, an integrated solution that handles 200 birds/hour with surgical precision. Ready to transform chaos into efficiency?

(evisceration table)

Unmatched Evisceration Table Technology

Why settle for outdated equipment? Our stainless steel evisceration table features laser-cut drainage grooves and antimicrobial coating. Ergonomic design reduces worker fatigue by 55%. Self-cleaning nozzles slash sanitation time. Intuitive controls anyone can master in 10 minutes. Built for 24/7 operation without compromise.

Seamlessly pair it with our table top chicken plucker - 98% feather removal in 45 seconds. Our table top vacuum packaging machine extends shelf life by 120%. All components communicate through our SmartProcess OS™. See real-time yield data. Monitor sanitation cycles. Predict maintenance needs.

Evisceration Table Showdown: Why We Dominate

| Feature | PremiumPro Series | Competitor A | Competitor B |

|---|---|---|---|

| Throughput Capacity | 200 birds/hour | 150 birds/hour | 120 birds/hour |

| Water Usage | 1.2 gal/min | 2.5 gal/min | 3.1 gal/min |

| Sanitation Time | 15 minutes | 45 minutes | 55 minutes |

| 5-Year ROI | 162% | 87% | 63% |

Customized Evisceration Solutions

Your operation is unique. Your equipment shouldn't be generic. Choose modular upgrades:

→ Precision-Pak™ Add-on for our vacuum packaging machine: Portion-controlled sealing

→ AquaBlast™ Integration: Waterjet cleaning during evisceration

→ ScaleSmart™ Feature: Automatic weight grading on table surface

Our engineers create turnkey solutions for plants from 500 to 50,000 birds/day.

Proven Success in Poultry Plants

Golden Valley Farms upgraded to our system last quarter: 37% higher throughput. $2,200 weekly savings on water and labor. Their evisceration table runs 19 hours daily with zero downtime.

- Mike Richardson, Plant Manager

Your Turn to Modernize: Act Now!

Stop patching old equipment. Our American-engineered evisceration tables come with industry-best 5-year warranty. Installation completed in 72 hours. Zero-interest financing available.

Limited Offer: First 10 orders this month receive FREE table top chicken plucker ($4,200 value). Why wait? Efficiency is just one click away.

Call (888) 555-0197 | 24/7 Support | Made in USA

(evisceration table)

FAQS on evisceration table

Here are 5 English FAQs created around the specified in HTML format:Q: What is an evisceration table used for in poultry processing?

A: An evisceration table provides a dedicated sanitary workspace for organ removal during poultry processing. Its sloped, stainless steel design facilitates blood drainage while meeting USDA hygiene standards. This specialized surface prevents cross-contamination during gutting operations.

Q: How does a table top chicken plucker integrate with processing stations?

A: Compact table top chicken pluckers mount directly to existing workbenches alongside evisceration tables. Their rotating rubber fingers efficiently remove feathers within arm's reach of processing zones. This space-saving configuration creates a seamless workflow from plucking to evisceration.

Q: Why pair table top vacuum packaging with poultry processing tables?

A: Table top vacuum packaging machines allow immediate sealing after evisceration on adjacent stations. This proximity maintains cold chain integrity by minimizing product movement before packaging. Countertop models support portion-controlled packaging directly at processing stations.

Q: What safety features should evisceration tables include?

A: Quality evisceration tables feature integrated splash guards and knife-proof surfaces to contain biological hazards. Non-slip footrails and radiused corners enhance operator safety during wet operations. All designs must incorporate NSF-certified materials for food contact surfaces.

Q: Are these table top systems suitable for small-scale poultry farms?

A: Absolutely - compact table top systems provide affordable processing solutions for small operations. Their modular design allows separate acquisition of pluckers, evisceration tables, and sealers as budgets permit. Units connect to standard electrical outlets without requiring industrial infrastructure.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025