Premium Poultry Breeding Cages | Modern Layer Systems for Sale

Aug . 19, 2025 01:00 Back to list

Premium Poultry Breeding Cages | Modern Layer Systems for Sale

The Evolution and Precision Engineering of Poultry Breeding Cages for Modern Agriculture

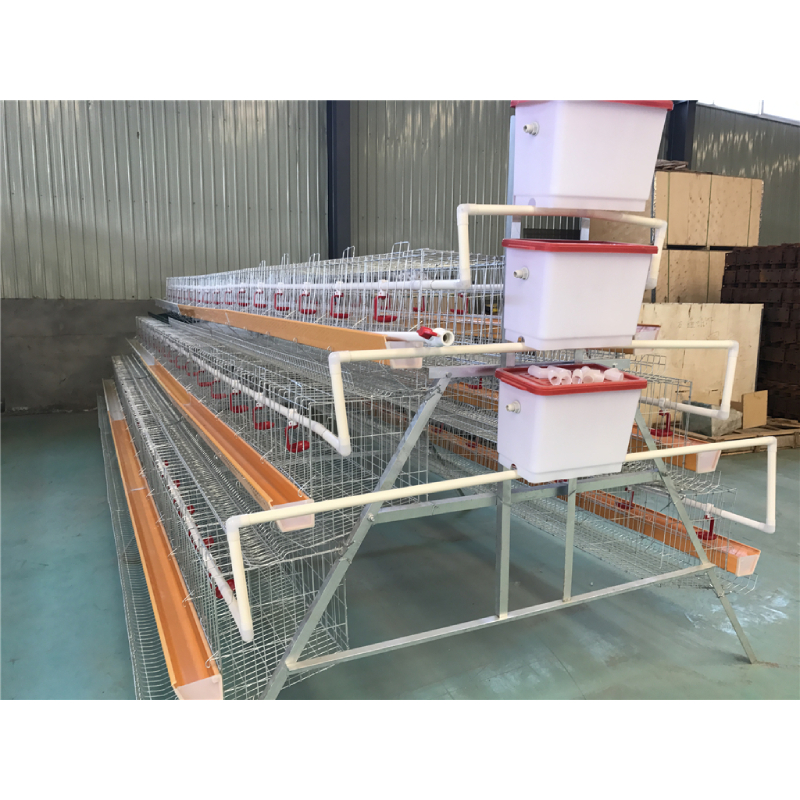

The contemporary poultry industry is undergoing a significant transformation, driven by an imperative for enhanced efficiency, sustainable production, and improved animal welfare standards. Central to this evolution are advanced housing solutions, notably the poultry breeding cage, which has transcended its traditional role as a simple enclosure to become a sophisticated, precision-engineered environment. These systems are meticulously designed to optimize the health and productivity of layer hens, directly impacting egg production rates and operational costs for commercial farms. The global trend towards higher bird densities per square meter, coupled with stringent bio-security requirements, has accelerated the adoption of multi-tier battery cage systems over conventional floor rearing. This paradigm shift offers distinct advantages, including superior hygienic conditions, reduced disease transmission risks, and more efficient resource utilization. Modern poultry breeding solutions are increasingly integrating automation and smart technologies, influencing every facet of their design and functionality, from advanced feeding and watering mechanisms to sophisticated environmental control and waste management systems. Such innovations contribute significantly to creating a highly controlled and productive agricultural ecosystem. The escalating demand for durable, high-quality materials and advanced manufacturing processes underscores the industry's focus on longevity, minimal maintenance, and consistent performance even in the most demanding farm environments. Our `96,120,128,160 Birds Layer Poultry Battery Chicken Cages` are a testament to this commitment, meticulously engineered to meet the rigorous demands of commercial egg production facilities. These systems are specifically designed to facilitate optimal bird well-being, which directly translates into improved laying performance, enhanced egg quality, and ultimately, greater profitability for poultry enterprises worldwide, emphasizing energy efficiency through optimized resource distribution and reduced overall operational expenditures. This comprehensive overview explores the technical intricacies, application benefits, and stringent manufacturing standards that define the forefront of poultry farming infrastructure today, providing B2B decision-makers with the insights necessary to make informed investments.

Deep Dive into Poultry Breeding Cage Manufacturing: A Process of Precision and Durability

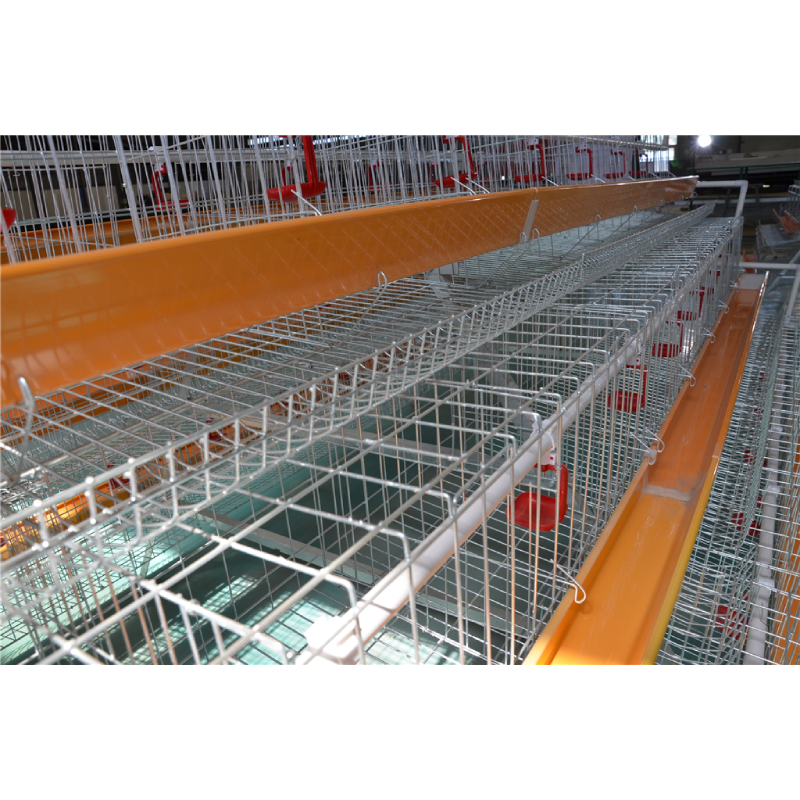

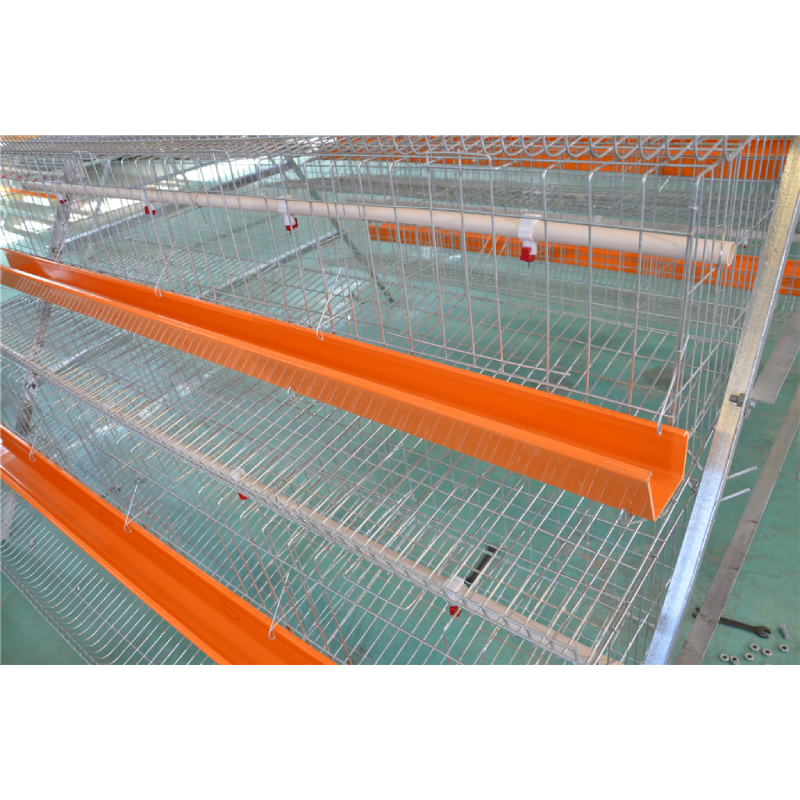

The manufacturing of advanced poultry breeding cage systems, such as our `96,120,128,160 Birds Layer Poultry Battery Chicken Cages`, is a testament to meticulous multi-stage engineering that prioritizes unparalleled durability, optimal hygiene, and maximum bird comfort. The process commences with the stringent selection of high-grade raw materials, primarily low-carbon steel wire (e.g., Q235), chosen for its exceptional tensile strength, ductility, and weldability, which are indispensable qualities for forming complex mesh structures that withstand the demands of continuous operation. This raw steel undergoes a precise wire drawing process, where its diameter is progressively reduced to meet exact specifications, followed by an annealing treatment to enhance its flexibility and prepare it for subsequent shaping and joining. The core fabrication phase involves state-of-the-art automated welding techniques, predominantly resistance spot welding, which ensures the creation of incredibly robust and uniformly structured mesh panels. This advanced automation guarantees consistency across thousands of weld points, a critical factor for the overall structural integrity and long-term stability of the entire cage system. Following welding, the material undergoes a crucial surface treatment: hot-dip galvanization. In this process, the steel mesh is fully immersed in a bath of molten zinc maintained at approximately 450°C. This creates a metallurgically bonded, highly resistant zinc coating that provides superior protection against the severe corrosive effects of moisture, ammonia, and various disinfectants commonly found in poultry house environments. The thickness and uniformity of this protective zinc layer are rigorously inspected to meet or exceed stringent international standards, including ISO 1461, which specifies hot-dip galvanized coatings on fabricated iron and steel articles. This meticulous attention to detail ensures an extended service life often surpassing two decades, even under the most challenging operational conditions, significantly reducing the need for premature replacements and associated costs, thereby offering substantial anti-corrosion advantages. Beyond the primary mesh structure, all ancillary components—including precision-engineered feeding troughs, automated watering lines, and advanced manure conveyor belts—are manufactured with an equally high degree of precision and quality. Feeding troughs are typically crafted from highly durable, food-grade PVC or robust galvanized steel, expertly shaped to minimize feed wastage while providing unrestricted access for the birds. Water lines are equipped with state-of-the-art stainless steel nipple drinkers, specifically designed for leak-free operation and effortless activation, ensuring a continuous supply of clean, fresh water on demand, crucial for avian health and productivity. The plastic components, such as feed pipes and some watering accessories, are often produced using advanced injection molding techniques, guaranteeing superior dimensional accuracy, consistent material properties, and a smooth finish that is easy to clean and sanitize. Every single component, regardless of its material, undergoes stringent quality control checks at multiple stages of the manufacturing pipeline. These checks encompass comprehensive visual inspections for any surface defects, precise dimensional verifications utilizing advanced precision instruments, and detailed material composition analyses to confirm compliance with specifications. Furthermore, both destructive and non-destructive testing methodologies, such as accelerated salt spray tests to assess corrosion resistance and rigorous load-bearing tests for structural integrity, are routinely performed to validate the product's long-term performance and endurance. Adherence to internationally recognized quality management systems like ISO 9001 is paramount, ensuring that every poultry cage mesh component seamlessly integrates into a reliable and highly efficient system. The entire manufacturing ecosystem is strategically geared towards producing a resilient product that performs flawlessly in modern poultry farming operations, supporting high bird densities while upholding optimal hygiene and maximizing productivity. This meticulous process significantly contributes to energy efficiency by optimizing resource distribution and substantially reducing overall operational expenditures for poultry producers.

Technical Parameters and Unrivaled Advantages of Our Layer Poultry Battery Cages

Our distinguished range of `96,120,128,160 Birds Layer Poultry Battery Chicken Cages` exemplifies the cutting-edge of `modern poultry cage` design, seamlessly integrating robust technical specifications with a suite of practical advantages that directly empower large-scale egg production facilities. The foundational material utilized is premium-grade Q235 steel wire, specifically chosen for its exceptional strength-to-weight ratio, superior weldability, and inherent durability, which collectively form the backbone of a resilient cage structure. This steel undergoes a meticulous hot-dip galvanization process, resulting in a zinc coating thickness consistently ranging from 275 g/m² to an impressive 400 g/m². This substantial coating provides unparalleled corrosion resistance, guaranteeing an operational lifespan often exceeding two decades, even when exposed to the highly corrosive conditions prevalent in poultry environments, significantly extending the service life of each poultry breeding cage. Each cage tier is engineered with meticulous precision, featuring specific dimensions that maximize space utilization while rigorously adhering to international animal welfare standards, typically providing between 450-500 cm² of floor space per bird. This optimal spatial allocation is crucial for ensuring bird comfort and facilitating natural movement within the confined system, thereby preventing stress-induced declines in egg production and promoting overall flock health. The wire mesh gauge is strategically varied across the cage: the bottom mesh, critical for egg collection and bird support, typically ranges from 2.0-2.2 mm, ensuring optimal egg roll-out without damage. Conversely, the side and top mesh utilize a thicker gauge of 3.0-3.5 mm, providing essential structural rigidity and containment. This precise engineering facilitates superior ventilation, minimizes egg damage during collection, and streamlines the efficient removal of manure, all contributing to a more hygienic and productive environment. The advanced design further incorporates fully automated feeding systems that utilize specialized feeding troughs or high-precision trolley feeders. These systems ensure uniform feed distribution across all cages, drastically reducing manual labor requirements and minimizing feed wastage, which are critical factors in managing and reducing operational overheads for large-scale poultry cages for layers. The integrated automated drinking system is equipped with high-quality, corrosion-resistant stainless steel nipple drinkers, meticulously designed to provide continuous, on-demand access to fresh, clean water while effectively preventing spillage and mitigating the risk of bacterial contamination. This ensures superior hygiene within the `modern poultry cage` environment, promoting optimal bird hydration and health. Manure removal systems, frequently employing durable polypropylene conveyor belts, are engineered for highly efficient waste collection, drying, and transportation. This innovation drastically reduces ambient ammonia levels within the poultry house, significantly improving air quality for both birds and personnel. Beyond environmental benefits, this streamlined waste management simplifies the process of converting manure into valuable fertilizer, potentially opening up additional revenue streams. A paramount advantage of these battery systems is their extraordinary capacity to increase bird density by up to 3-4 times compared to traditional floor rearing methods. This translates into substantial space savings, allowing for higher production volumes within a smaller footprint and reducing land requirements for large-scale operations. Furthermore, the contained and controlled environment of the cages facilitates superior bio-security protocols, significantly minimizing direct contact between birds and their feces, thereby dramatically reducing the incidence and spread of disease outbreaks. This controlled setting also enables precise monitoring of individual bird health and egg production metrics, allowing for targeted interventions and ultimately enhancing overall flock performance and uniformity. The inherent design of these systems contributes directly to unparalleled operational efficiency, substantially reduced labor costs due-to-automation, and a remarkable improvement in feed conversion ratios (FCR), all of which directly and positively impact the profitability and long-term sustainability of commercial poultry farms utilizing our advanced layer poultry cages for sale. The systematic approach in design and application ensures an unparalleled return on investment for our clients.

Key Product Specifications Table for Yize Machine Layer Poultry Cages

| Parameter | Specification for `96,120,128,160 Birds Layer Poultry Battery Chicken Cages` |

|---|---|

| Bird Capacity Per Set | 96, 120, 128, 160 birds (Configurable based on tiers and cells) |

| Standard Cage Dimensions (L x W x H) | Typically 2150mm x 380mm x 380mm (per 4-cell cage unit) |

| Primary Material | High-Strength Q235 Low-Carbon Steel Wire |

| Surface Treatment | Hot-dip Galvanization (Zinc coating thickness: 275-400 g/m²) |

| Wire Gauge (Bottom Mesh) | 2.0 - 2.2 mm (Optimized for gentle egg roll-out and bird support) |

| Wire Gauge (Side/Top Mesh) | 3.0 - 3.5 mm (Ensures robust structural integrity and containment) |

| Design Service Life | Exceeds 20 years under proper maintenance and operation |

| Feeding System | Automated Trolley Feeder or Chain Feeding System (Customizable) |

| Watering System | Automated Nipple Drinking System (High-grade Stainless Steel) |

| Manure Removal | Automated Belt Conveyor System (Durable Polypropylene) |

| Egg Collection | Automated Egg Collection System (Optional integration) |

Comparative Analysis: A-Type vs. H-Type Battery Cages for Poultry Breeding

| Feature | A-Type (Inclined Layer Cage) | H-Type (Vertical Tier Cage) |

|---|---|---|

| Structural Design | Pyramid-like, inclined tiers; suitable for open-sided houses. | Multi-story vertical tiers; designed for fully enclosed houses. |

| Space Utilization & Density | Good for smaller to medium farms; less bird density per footprint. | Extremely high density, maximizing birds per square meter; ideal for large-scale operations. |

| Manure Removal System | Typically uses manure scrapers or manual pit systems; less frequent removal. | Automated polypropylene conveyor belts beneath each tier for daily, efficient removal. |

| Ventilation Requirements | Relies more on natural cross-ventilation; simpler setup. | Requires sophisticated forced ventilation systems for optimal air quality and temperature control. |

| Automation Level | Can be semi-automatic (manual egg collection, feeding often automated). | Typically fully automated, encompassing feeding, watering, egg collection, and manure removal. |

| Initial Investment Cost | Generally lower capital outlay. | Higher initial investment due to advanced automation and structural complexity. |

| Operational Efficiency | Good efficiency but higher labor input compared to H-type. | Superior operational efficiency, significantly reduced labor costs due to comprehensive automation. |

Application Scenarios, Customization, and Proven Success in Poultry Farming

The remarkable versatility of our poultry breeding cage systems enables their seamless integration across a diverse spectrum of poultry farming operations, catering effectively to everything from rapidly expanding small-to-medium enterprises (SMEs) to sprawling industrial-scale layer farms. These advanced systems are ideally suited for high-volume commercial egg production, a sector where maximizing output per unit of space and rigorously maintaining optimal hygiene standards are absolutely paramount for profitability. Specifically, our battery cages find extensive application in large-scale layer houses, designed to accommodate tens of thousands, or even hundreds of thousands, of birds, where comprehensive automation plays an undeniably critical role in achieving peak efficiency and robust financial returns. Beyond purely commercial settings, these sophisticated cages are also proving invaluable for leading research institutions focusing on poultry nutrition, genetics, and sophisticated disease control studies, offering a highly controlled, consistent, and bio-secure environment essential for accurate scientific investigations. Furthermore, vocational training centers and educational farms globally benefit from these systems, providing aspiring poultry professionals with practical, hands-on experience in managing and operating modern poultry infrastructure and automation technologies. The inherent design advantages, such as significantly enhanced bio-security through drastically reduced bird-feces contact, make our systems indispensable for preventing costly disease outbreaks and ensuring sustained flock health. Moreover, the modular nature of our poultry breeding cage designs allows for highly flexible installation in a wide array of barn sizes and configurations, seamlessly accommodating various operational scales and spatial constraints while consistently delivering superior performance metrics in terms of egg yield, feed conversion efficiency, and overall bird well-being, proving their adaptability in challenging environments.

Recognizing that every poultry farm possesses its own unique set of requirements, environmental conditions, and operational nuances, we pride ourselves on offering comprehensive customization solutions for our poultry breeding cage systems. Our team of highly skilled engineers collaborates intensely with clients from the initial conceptualization phase through to final implementation, meticulously designing layouts that precisely optimize space utilization, ventilation efficacy, and ease of access for routine operations. This ensures that the chosen configuration perfectly aligns with the client's specific farm structure, existing infrastructure, and overarching production goals. Customization extends beyond mere physical dimensions, encompassing the tailoring of cage sizes, the number of tiers (e.g., 3-tier, 4-tier, 5-tier configurations), and the precise length of rows to seamlessly fit into existing poultry houses or facilitate the efficient planning of new construction projects. Moreover, customization is deeply integrated into our automated systems: clients have the flexibility to select from various sophisticated levels of automation for critical processes such as feeding, watering, egg collection, and manure removal, ranging from robust semi-automated setups to fully integrated, data-driven smart-farm solutions. For example, forward-thinking farmers can opt for advanced environmental control systems that autonomously regulate temperature, humidity, and ventilation, thereby creating an optimal microclimate that significantly enhances bird comfort and productivity. Material choices for specific components, such as different grades of galvanized steel or specialized UV-resistant PVC for certain parts, can also be adapted based on prevailing environmental conditions, specific regulatory compliance requirements, and budgetary considerations, all while maintaining our stringent quality benchmarks and adherence to international standards for `poultry cages for layers`. This bespoke approach ensures that every solution we deliver is not merely a product, but a strategic, long-term investment engineered for maximum return on investment and sustained operational excellence, meticulously addressing the specific challenges and unique opportunities presented by each individual poultry breeding cage installation.

Our unwavering commitment to delivering exceptional quality and ensuring profound client success is powerfully underscored by a robust and expanding portfolio of real-world application cases and compelling customer testimonials that vividly highlight the tangible and transformative benefits realized by implementing our systems. As a compelling example, a large-scale layer farm situated in Southeast Asia, which had been grappling with escalating labor costs and persistent challenges in disease management, strategically implemented our 120-bird capacity `poultry cages for layers` across five of their extensive poultry sheds. Within a mere six months following installation, they reported an impressive 15% reduction in labor expenditure, directly attributable to the enhanced automation features. Furthermore, they observed a significant 20% decrease in mortality rates, a direct consequence of the vastly improved hygiene and meticulously controlled environmental conditions facilitated by our cages. Crucially, the farm achieved and consistently maintained a remarkable 90%+ lay rate, leading to a substantial increase in overall profitability and a swift return on their initial investment. In another instance, a progressive mid-sized farm in Eastern Europe opted for our `modern poultry cage` solution, specifically integrating the advanced manure belt removal system. This implementation dramatically reduced ammonia levels within their barns, plummeting from an unhealthy 50 ppm to below 15 ppm, which directly resulted in a significant improvement in bird respiratory health and a notable enhancement in feed conversion efficiency. These real-world, quantifiable results serve as undeniable proof of our profound expertise and extensive experience in consistently delivering high-performance, exceptionally reliable `layer poultry cages for sale` that not only address but decisively overcome critical industry challenges. Our long-standing and deeply valued relationships with clients, meticulously built upon trust, consistent product performance, and an unwavering commitment to post-sales support, firmly reinforce our authoritative position as a leading innovator and trusted provider of comprehensive poultry farming solutions globally. These success stories are a powerful testament to our dedication to engineering solutions that are not merely technically sound but are also economically viable, environmentally responsible, and intrinsically sustainable, ensuring that our clients achieve their production targets with unparalleled efficiency, ethical integrity, and long-term viability, embodying the highest standards for poultry breeding cage excellence.

Ensuring Trustworthiness: FAQs, Comprehensive Warranty, and Dedicated Customer Support

Building and maintaining profound trust with our esteemed B2B partners forms the absolute cornerstone of our operational philosophy, and our meticulously structured approach to customer support, comprehensive warranty provisions, and transparent communication reflects this unwavering commitment. We profoundly understand that investing in a state-of-the-art poultry breeding cage system constitutes a significant strategic decision for any commercial poultry enterprise, and therefore, our expansive support framework is intricately designed to provide complete peace of mind throughout every stage of the product lifecycle. Our delivery cycle is rigorously managed to ensure the most timely and efficient dispatch of orders, typically ranging from a swift 15 to 30 business days from the precise order confirmation, with the exact duration contingent upon the level of customization required and the overall quantity of cages ordered. Each critical stage within our supply chain, from the initial procurement of high-grade raw materials to the meticulous final packaging and the intricate logistics of international shipping, is monitored with unparalleled rigor to proactively prevent any potential delays and to meticulously ensure the absolute product integrity upon its arrival at the client's designated location. For international shipments, we provide a comprehensive suite of necessary documentation, including official certificates of origin, detailed quality inspection reports, and exhaustive packing lists, all designed to facilitate an exceptionally smooth customs clearance process and streamline the setup at the client's facility. This unwavering dedication to logistical excellence minimizes any potential downtime for our valued clients, thereby allowing for the rapid deployment and immediate activation of their new poultry breeding cage systems, which in turn optimizes their operational continuity and significantly accelerates their return on investment from the very first day of installation, demonstrating our commitment to reliable delivery.

Frequently Asked Questions (FAQ) about Poultry Breeding Cages

-

Q1: What is the expected service life and durability of your poultry breeding cage systems?

A1: Our hot-dip galvanized cages are engineered for exceptional, long-term durability, boasting a robust service life that consistently exceeds 20 years under normal operating conditions. This remarkable longevity is directly attributed to the superior anti-corrosion properties afforded by the thick, uniformly applied zinc coating, which ranges from 275-400 g/m², ensuring maximum protection against harsh poultry house environments. -

Q2: Can your poultry breeding cages be specifically customized to fit unique farm layouts or varying bird capacities?

A2: Absolutely. We pride ourselves on offering comprehensive customization options, including precise variations in cage dimensions, flexible tier configurations (e.g., A-type or H-type), and highly tailored levels of automation for feeding, watering, manure removal, and egg collection. These bespoke solutions are designed to perfectly fit your existing or planned poultry house dimensions and to achieve your desired bird capacity, ranging efficiently from 96 to 160 birds per individual set, and scalable for entire large-scale farm operations. -

Q3: What specific maintenance procedures are typically required for these advanced battery cage systems to ensure longevity?

A3: Thanks to the robust materials and highly automated features, maintenance for our systems is remarkably minimal. Routine tasks generally include regular cleaning of manure belts and feeding troughs, periodic checks of nipple drinkers for any potential blockages, and ensuring proper tension and alignment on conveyor belts. Our poultry breeding cage systems are intelligently designed for unparalleled ease of access, simplifying all routine checks and necessary cleaning protocols. -

Q4: What are the distinct advantages of choosing hot-dip galvanization over alternative coating methods for poultry breeding cage materials?

A4: Hot-dip galvanization provides a significantly thicker, more uniform, and metallurgically bonded zinc coating when compared to electro-galvanization or powder coating. This results in far superior corrosion resistance, making the cages exceptionally more resilient to the highly corrosive effects of ammonia, moisture, and disinfectants prevalent in poultry environments, thereby ensuring a substantially longer operational lifespan and markedly reducing long-term replacement costs, providing excellent value over time.

Comprehensive Warranty and Dedicated After-Sales Support

We unequivocally stand behind the exceptional quality and superior performance of our poultry breeding cage solutions with a comprehensive and robust warranty program. All core structural components, most notably the hot-dip galvanized mesh, are proudly backed by an extensive 10-year warranty against any manufacturing defects and premature corrosion, provided that standard operational guidelines and recommended maintenance procedures are diligently followed. All integrated automated systems and critical electrical components carry a standard 1 to 2-year warranty, contingent upon the specific part and its manufacturer's guarantee. Our profound commitment to client success extends far beyond the point of sale, reinforced by a robust after-sales support infrastructure. This includes readily available remote technical assistance, guaranteed access to genuine spare parts, and, where feasible, expert on-site guidance for installation and complex troubleshooting. Our dedicated team of highly experienced and certified technicians is always available to provide unparalleled expert advice and innovative solutions, meticulously ensuring that your significant investment continues to operate at peak efficiency and optimal productivity for decades to come. Furthermore, we provide detailed, user-friendly operation manuals and comprehensive training resources to empower your on-site staff with the essential knowledge and practical skills required to manage and maintain the systems effectively and autonomously. This extensive and multi-faceted support infrastructure is a foundational cornerstone of our trustworthiness, guaranteeing that our clients receive not just a premium product, but a complete, reliable, and enduring solution for all their advanced poultry farming needs, fostering long-term partnership and mutual success in the industry.

References

- Food and Agriculture Organization of the United Nations (FAO). (2020). The State of Food and Agriculture 2020. Moving forward on climate change, agriculture and food security. Rome, Italy.

- Poultry Science Association. (2021). Journal of Poultry Science Research, Volume 100, Issue 3. Impact of Housing Systems on Layer Hen Performance and Welfare.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 - Quality management systems — Requirements.

- European Commission. (2018). Animal Welfare Regulations for Laying Hens. Directorate-General for Health and Food Safety.

- National Research Council (NRC). (1999). Guide for the Care and Use of Laboratory Animals (7th ed.). Washington, D.C.: National Academies Press.

-

Efficient & Sustainable Chick Brooding Cage Systems for Modern Poultry Farming

NewsNov.24,2025

-

Cage for Chick: Optimizing Poultry Care for Global Food Security

NewsNov.23,2025

-

Baby Chicks Cage – Global Solutions for Sustainable Poultry Farming

NewsNov.22,2025

-

Baby Chick Cage: The Essential Guide to Brooding Solutions for Poultry Farmers

NewsNov.22,2025

-

Understanding Square Grain Silos: Global Impact, Benefits, and Trends

NewsNov.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Automated Feeding&Watering

NewsNov.21,2025