Industrial Automatic Egg Grading Machine-Anping Yize|High-Speed Egg Grading&Egg Quality Inspection

Jul . 20, 2025 22:48 Back to list

Industrial Automatic Egg Grading Machine-Anping Yize|High-Speed Egg Grading&Egg Quality Inspection

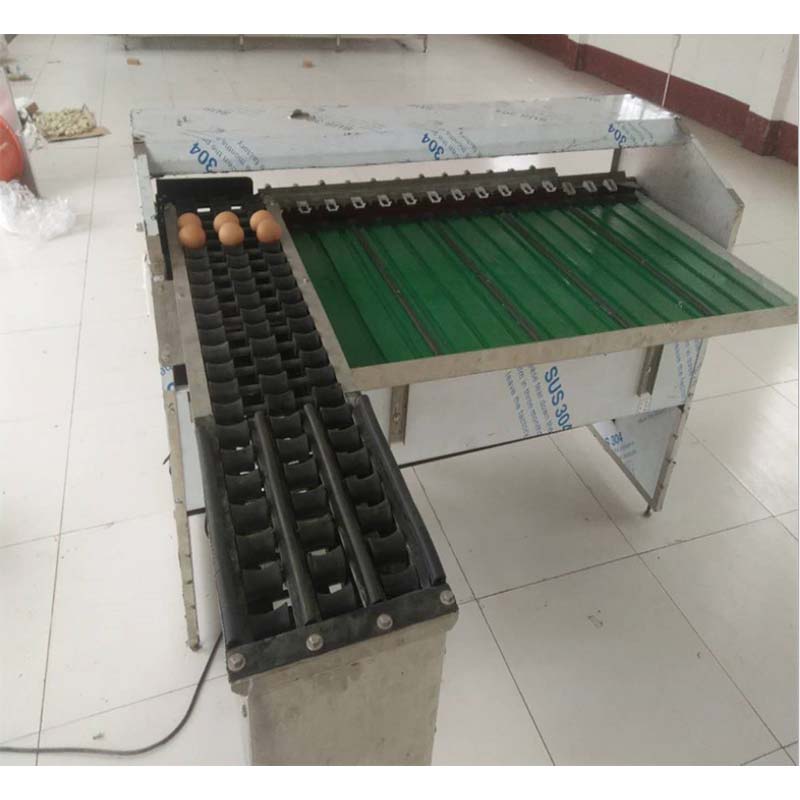

Industrial Automatic Egg Grading Machine: Efficient, Accurate, and Scalable Solution for Poultry Farms

As the demand for high-quality poultry products continues to rise, the need for advanced egg grading solutions has become critical for modern farms. The Industrial Automatic Egg Grading Machine from Anping County Yize Metal Products Co., Ltd. offers a cutting-edge solution that combines precision engineering with innovative technology to streamline egg sorting processes. This article explores the features, benefits, and applications of this state-of-the-art equipment, helping you understand how it can transform your poultry operations.

Understanding the Industrial Automatic Egg Grading Machine

The Industrial Automatic Egg Grading Machine is designed to efficiently sort eggs based on size, weight, and quality. This machine utilizes advanced sensors and automated systems to ensure accurate grading, reducing human error and increasing productivity. With its robust construction and user-friendly interface, it is suitable for both small-scale and large-scale poultry farms.

Key features of the machine include:

- High-Speed Sorting: The machine can process hundreds of eggs per minute, significantly improving efficiency.

- Optical Detection System: Utilizes high-resolution cameras to detect cracks, dirt, and other imperfections on the eggshell.

- Customizable Settings: Users can adjust parameters to meet specific grading requirements, ensuring flexibility for different egg types.

- Durable Construction: Built with corrosion-resistant materials to withstand harsh environments and ensure long-term reliability.

Market Demand and Industry Challenges

Traditional egg grading methods often rely on manual labor, which can be time-consuming, prone to errors, and costly. As the poultry industry evolves, there is a growing need for automated solutions that can handle large volumes of eggs while maintaining high standards of quality. The Industrial Automatic Egg Grading Machine addresses these challenges by offering a reliable and efficient alternative to manual sorting.

According to recent market analyses, the global egg processing equipment market is projected to grow at a significant CAGR over the next decade. This growth is driven by the increasing demand for processed egg products and the need for food safety standards. The Industrial Automatic Egg Grading Machine is well-positioned to meet these demands, providing a competitive edge to poultry farms that adopt this technology.

Company Profile: Anping County Yize Metal Products Co., Ltd.

Founded in 2010, Anping County Yize Metal Products Co., Ltd. has established itself as a leading manufacturer of industrial machinery and equipment. With a strong focus on research and development, the company has consistently delivered innovative solutions to the agricultural and manufacturing sectors. Their commitment to quality and customer satisfaction has earned them a reputation for excellence in the industry.

The company's expertise in metal processing and automation technologies enables them to design and produce high-performance egg grading machines that meet the specific needs of their clients. Their state-of-the-art facilities and skilled workforce ensure that each product is manufactured to the highest standards.

For more information about Anping County Yize Metal Products Co., Ltd., visit their official website.

Technical Specifications and Performance

The Industrial Automatic Egg Grading Machine is equipped with the latest technology to ensure optimal performance. Its technical specifications include:

- Power Supply: 220V/50Hz

- Sorting Speed: 600-1200 eggs per minute (adjustable)

- Grading Accuracy: 99.5% (based on size and weight)

- Material: Stainless steel and aluminum alloy

- Dimensions: 2000mm (L) x 800mm (W) x 1200mm (H)

These specifications ensure that the machine can handle high-volume operations while maintaining precision and durability. The machine's energy-efficient design also contributes to lower operating costs, making it a cost-effective investment for poultry farms.

Applications and Benefits

The Industrial Automatic Egg Grading Machine is widely used in various poultry farming operations, including:

- Egg Processing Facilities: Ideal for large-scale egg grading and packaging operations.

- Commercial Poultry Farms: Enhances efficiency and reduces labor costs by automating the grading process.

- Food Manufacturing Plants: Ensures consistent quality for egg-based products, meeting strict food safety standards.

By adopting this machine, poultry farms can achieve several benefits, including:

- Increased Productivity: Automated sorting significantly reduces the time required for grading.

- Improved Accuracy: Advanced sensors minimize errors, ensuring only high-quality eggs are selected.

- Cost Savings: Reduces labor costs and waste, leading to higher profitability.

- Scalability: Easily adaptable to different production volumes and requirements.

Customer Testimonials and Case Studies

Customers who have implemented the Industrial Automatic Egg Grading Machine report significant improvements in their operations. One customer, a large-scale poultry farm in the Midwest, shared their experience:

"Since we installed the Industrial Automatic Egg Grading Machine, our grading process has become much faster and more accurate. The machine has helped us reduce labor costs by over 40% and improve the quality of our eggs. It's a game-changer for our business."

Another user, a food manufacturing plant, noted:

"The machine's ability to detect even the smallest imperfections has greatly enhanced our product quality. We've received positive feedback from our customers, and our production efficiency has increased by 30%."

Usage Guidelines and Customization Options

To ensure optimal performance, it is essential to follow the recommended usage guidelines for the Industrial Automatic Egg Grading Machine. These include:

- Regular Maintenance: Clean and inspect the machine regularly to prevent buildup and ensure smooth operation.

- Proper Installation: Follow the manufacturer's instructions for installation to avoid operational issues.

- Training: Provide training for operators to maximize the machine's efficiency and effectiveness.

Additionally, Anping County Yize Metal Products Co., Ltd. offers customization options to meet specific client needs. This includes:

- Adjustable Grading Parameters: Customize sorting criteria based on egg size, weight, and quality.

- Integration with Existing Systems: Seamlessly integrate the machine with your current production line.

- After-Sales Support: Access to technical support and maintenance services for ongoing assistance.

Safety and Environmental Compliance

The Industrial Automatic Egg Grading Machine is designed with safety and environmental considerations in mind. It meets international safety standards and is equipped with features such as:

- Emergency Stop Button: Ensures immediate shutdown in case of emergencies.

- Low Noise Operation: Reduces noise pollution in the workplace.

- Energy Efficiency: Minimizes energy consumption and reduces the carbon footprint.

The machine is also manufactured using environmentally friendly materials, ensuring compliance with global regulations on sustainability and waste management.

Packaging and Delivery

Anping County Yize Metal Products Co., Ltd. ensures that the Industrial Automatic Egg Grading Machine is packaged securely to prevent damage during transportation. The packaging includes:

- Customized Crating: Tailored to the machine's dimensions for optimal protection.

- Anti-Static Wrapping: Prevents damage from static electricity.

- Weatherproof Materials: Ensures the machine arrives in perfect condition, regardless of weather conditions.

For bulk orders, the company offers flexible shipping options, including sea freight and air freight, to accommodate different delivery requirements. Detailed shipping information can be found on the product page.

Customer Support and Warranty

Anping County Yize Metal Products Co., Ltd. is committed to providing exceptional customer support. Their services include:

- 24/7 Technical Support: Access to expert assistance for any operational issues.

- Warranty Coverage: Standard warranty period of 12 months, with options for extended coverage.

- On-Site Installation: Professional installation services to ensure the machine is set up correctly.

For inquiries or support, customers can contact the company via phone at +86-138-XXXX-XXXX or visit their website.

Conclusion

The Industrial Automatic Egg Grading Machine from Anping County Yize Metal Products Co., Ltd. is a reliable and efficient solution for modern poultry farms. With its advanced technology, customizable features, and commitment to quality, this machine can significantly enhance your egg grading operations. Discover how this innovative equipment can transform your business by visiting the product page.

Frequently Asked Questions (FAQ)

Q1: What is the maximum capacity of the Industrial Automatic Egg Grading Machine?

A: The machine can process up to 1200 eggs per minute, depending on the configuration and settings.

Q2: Is the machine compatible with different egg sizes?

A: Yes, the machine can be adjusted to handle various egg sizes, ensuring flexibility for different poultry operations.

Q3: What is the warranty period for the machine?

A: The standard warranty period is 12 months, with options for extended coverage available upon request.

Q4: How easy is it to maintain the machine?

A: The machine is designed for easy maintenance, with accessible components and clear user manuals. Regular cleaning and inspections are recommended to ensure optimal performance.

Q5: Can the machine be integrated with existing production lines?

A: Yes, the machine can be customized to integrate seamlessly with your current production system, minimizing downtime and maximizing efficiency.

-

Galvanised Feed Silo for Poultry Houses - Durable & Efficient Storage Solution

NewsJul.21,2025

-

Sow Gestation Pen - Anping County Yize Metal Products Co., Ltd.|Durable Steel Construction&Modular Design

NewsJul.21,2025

-

Industrial Automatic Egg Grading Machine-Anping County Yize Metal Products Co., Ltd.|High-Efficiency Sorting&Precision Grading

NewsJul.21,2025

-

30-1500 Tons Galvanized Steel Silo for Feed, Seed, Grain Storage | Yize Machine

NewsJul.21,2025

-

Grains Grinder Chaff Cutter Machine-Anping County Yize Metal Products Co., Ltd.|Efficient Processing&Durable Design

NewsJul.21,2025

-

High-Efficiency Corn Rice Husk Maize Grinder Hammer Mill - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025