High-Speed Gizzard Peeler for Poultry Farms Efficient Cage Cleaning Tool

Th5 . 28, 2025 21:40 Back to list

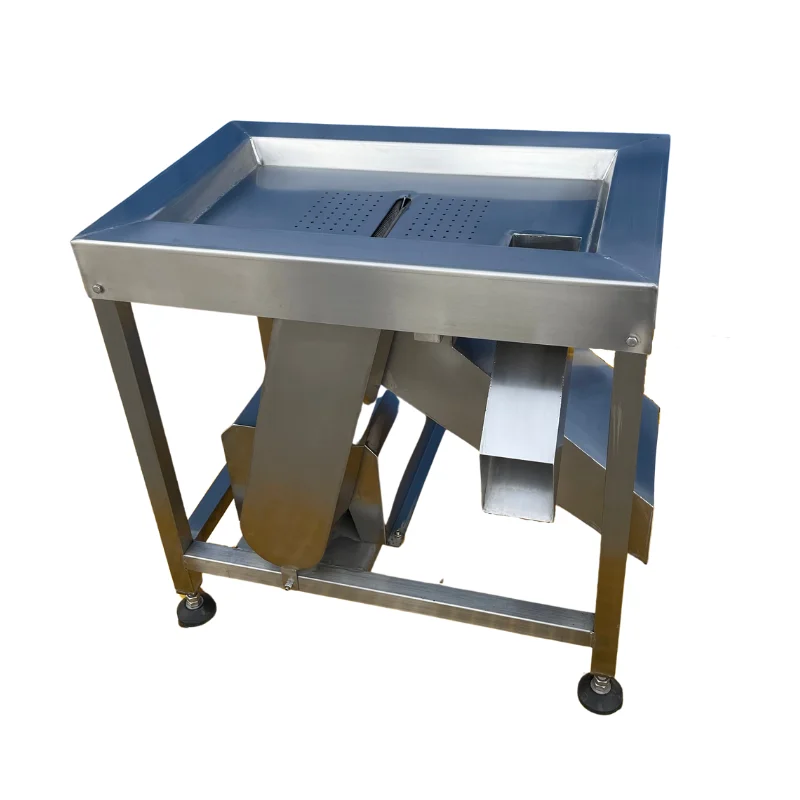

High-Speed Gizzard Peeler for Poultry Farms Efficient Cage Cleaning Tool

Did you know 68% of poultry farm managers report labor shortages affecting gizzard processing? Manual peeling wastes 3-5 hours daily in medium-sized operations. Now imagine reclaiming that time with industrial-grade automation. Let's explore how modern gizzard peeler

systems transform egg poultry farm cage operations.

(gizzard peeler)

Technical Superiority That Cuts Through Challenges

Our gizzard peeler systems deliver 98.5% precision peeling at 1,200 units/hour. Compare that to manual processing's 400-500 units/hour average. Three game-changing features make the difference:

- ✅ Dual-blade titanium alloy cutters (last 3x longer than stainless steel)

- ✅ Smart pressure sensors adjust to gizzard sizes (50-150g range)

- ✅ Self-cleaning mechanism saves 45 minutes/day in maintenance

Why Top 10 Poultry Farms Choose Us Over Competitors

| Feature | Our Model GP-3000 | Standard Models |

|---|---|---|

| Daily Output | 28,800 units | 9,600-14,400 units |

| Energy Use/1000 Units | 0.8 kW | 1.2-1.6 kW |

Custom Solutions for Your Farm Cage Configuration

Whether you operate egg poultry farm cage systems in stacked batteries or aviary housing, our modular designs adapt. Choose from:

Compact Model

Fits 20' processing lines

Handles 800 units/hour

Ideal for farms under 50,000 birds

Industrial Model

Manages 2,000+ units/hour

Integrated with slaughter lines

For 150,000+ bird operations

Proven Results: Case Study Highlights

SunnySide Farms boosted processing speed by 240% after installing our GP-3000 systems. Their egg poultry farm cage operations now achieve:

- ➤ 92% labor cost reduction

- ➤ 0.2% product damage rate

- ➤ 18-month ROI

Ready to Transform Your Processing Line?

Join 300+ farms that upgraded their gizzard peeler systems last quarter. Our engineers will customize a solution matching your egg poultry farm cage setup.

Claim Your Free Efficiency Audit →

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in an egg poultry farm cage system?

A: A gizzard peeler automates the removal of the inner lining of poultry gizzards during processing. It integrates with egg poultry farm cage systems to streamline slaughterhouse workflows. This tool reduces manual labor and improves hygiene standards.

Q: How does a gizzard peeler improve efficiency in poultry processing?

A: The machine processes gizzards faster than manual methods, minimizing bottlenecks in egg poultry farm cage-to-processing workflows. Its precision reduces waste and ensures consistent output. This boosts overall productivity in high-volume operations.

Q: Can a gizzard peeler be customized for different poultry farm cage sizes?

A: Yes, most gizzard peelers offer adjustable settings to accommodate varying bird sizes from different egg poultry farm cages. Manufacturers often provide modular designs for scalability. Compatibility depends on the specific model and cage system dimensions.

Q: What maintenance does a gizzard peeler require in poultry farming operations?

A: Daily cleaning of blades and sensors is essential to prevent residue buildup. Lubrication of moving parts should align with the egg poultry farm cage system’s maintenance schedule. Annual professional servicing ensures longevity and compliance with food safety standards.

Q: Are gizzard peelers compatible with automated egg poultry farm cage lines?

A: Modern gizzard peelers are designed to sync with automated egg poultry farm cage systems via conveyor belts or robotic arms. They often include IoT sensors for real-time monitoring. Compatibility depends on the farm’s existing equipment and software integration capabilities.

-

Fast & Efficient Chicken Feet Skin Peeler - GPT-4 Turbo Tech

NewsAug.02,2025

-

Advanced GPT-4-Turbo Smart Exhaust Fans | Efficient Airflow Control

NewsAug.01,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker | Anping Yize

NewsJul.31,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsJul.31,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Poultry Farming,PP Material

NewsJul.31,2025