Efficient Machine for Producing High-Quality Floating Fish Feed

Th8 . 21, 2024 21:29 Back to list

Efficient Machine for Producing High-Quality Floating Fish Feed

The Floating Fish Feed Making Machine Revolutionizing Aquaculture

In recent years, the aquaculture industry has experienced significant growth due to increasing global demand for fish and seafood. As a result, the need for innovative solutions to improve fish farming efficiency has never been more critical. One such innovation is the floating fish feed making machine, a technology that has been transforming the way fish feed is produced.

Understanding Floating Fish Feed

Floating fish feed is specially designed to provide optimal nourishment for various fish species. Unlike traditional sinking feeds, floating feeds remain on the surface, allowing farmers to monitor consumption and reduce waste. This not only enhances feed efficiency but also ensures a healthier environment for fish by preventing feed debris from accumulating at the bottom of the water body. The formulation of floating feed typically includes high-quality protein sources, vitamins, and minerals tailored to meet the nutritional needs of specific fish species.

The Role of the Fish Feed Making Machine

The floating fish feed making machine is integral to aquaculture operations, automating the production process and allowing for large-scale manufacturing of quality fish feed. These machines are engineered to create pellets that float, offering a uniform size and composition that promotes better digestibility and absorption of nutrients by the fish.

The core operation of the floating fish feed making machine involves several steps grinding, mixing, conditioning, pelleting, and drying. First, raw materials such as fish meal, corn, soybeans, and other ingredients are ground into a fine powder. Next, these ingredients are mixed thoroughly to create a homogenous blend. The mixture is then conditioned with steam to enhance binding properties and improve nutrient availability before being extruded through a pelletizing process, where it is shaped into pellets of various sizes and densities.

Advantages of Floating Fish Feed Making Machines

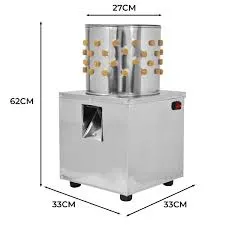

floating fish feed making machine

1. Efficiency and Scalability The floating fish feed making machine significantly increases production capacity compared to manual methods, allowing fish farmers to produce large quantities of feed in a shorter timeframe.

2. Customizable Formulation The technology enables precise control over the formulation of fish feed. Farmers can adjust the ingredients based on the specific nutritional requirements of different fish species, improving health and growth rates.

3. Cost-Effectiveness While the initial investment in a fish feed making machine may be substantial, the long-term savings in feed costs, reduced wastage, and improved fish growth performance can lead to a strong return on investment.

4. Quality Control Modern machines are equipped with advanced monitoring systems that ensure consistent quality in feed production. This reduces the risk of nutritional deficiencies in fish, ultimately leading to better marketable fish.

5. Environmental Benefits By minimizing feed waste and ensuring that feed is consumed efficiently, floating fish feed contributes to a healthier aquaculture ecosystem. This can result in reduced environmental impacts associated with water pollution and resource depletion.

Conclusion

The floating fish feed making machine represents a significant advancement in aquaculture technology. As the global demand for fish continues to rise, this machinery will play an essential role in meeting the needs of both fish farmers and consumers. By streamlining production processes, enhancing feed quality, and promoting sustainable practices, floating fish feed machines are revolutionizing the industry, ensuring that fish farming remains a viable and profitable venture for years to come. As the aquaculture sector continues to evolve, embracing such innovations will be crucial for sustainability and efficiency in food production.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025