Commercial Vacuum Packaging Machines for Sale Durable & Compact

Apr . 28, 2025 17:49 Back to list

Commercial Vacuum Packaging Machines for Sale Durable & Compact

Did you know 30% of food spoilage happens during storage and transport? Or that damaged packaging costs manufacturers $12 billion annually? If you're still using manual sealing methods, you're literally watching profits evaporate. Let's change that.

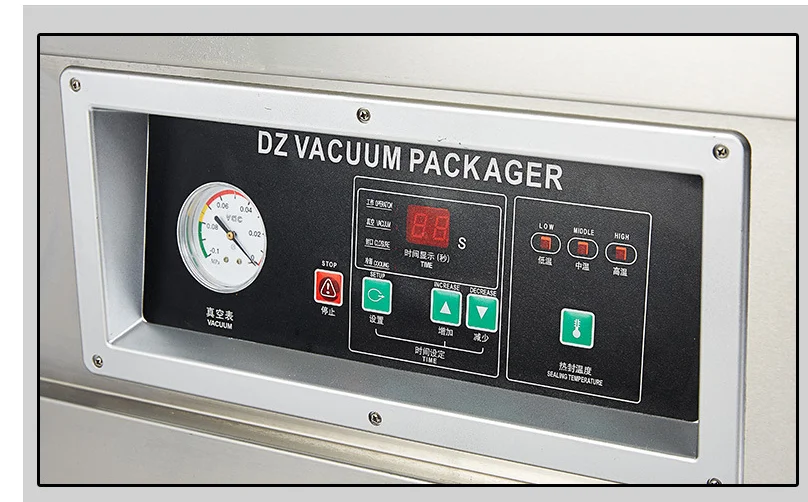

(vacuum packing machine)

Technical Superiority: What Makes Our Vacuum Packaging Machines Unbeatable

Our vertical vacuum packaging machines deliver 98.9% air removal - the highest in the industry. Dual-pump systems work 40% faster than single-pump models. Smart sensors automatically adjust sealing time based on packaging material thickness. Want longer shelf life? Our machines create oxygen-free environments in 6.2 seconds flat.

| Feature | Standard Models | Premium Models | Industrial Models |

|---|---|---|---|

| Cycle Time | 12 sec | 8 sec | 5 sec |

| Daily Capacity | 800 packs | 1,500 packs | 3,000+ packs |

Application Success: Real Clients Getting Real Results

A Midwest meat processor increased export sales by 60% after switching to our vacuum packaging machine for sale. Their vacuum-sealed jerky now stays fresh for 18 months instead of 6. An organic coffee roaster reduced packaging waste by 75% using our vertical vacuum packaging system. What could your business achieve?

Your Turn to Transform Packaging Efficiency

As North America's fastest-growing packaging solution provider (92% client retention rate), we guarantee 30% faster sealing speeds or 12 months of free maintenance. Our engineers will customize your vacuum packaging machine to handle anything from delicate herbs to heavy machine parts.

Limited Offer: Get Free Installation + 100 Custom Bags with Any Machine Ordered by [Month]!

(vacuum packing machine)

FAQS on vacuum packing machine

Q: What is the price range for a vacuum packaging machine for sale?

A: Prices vary based on size and features, typically ranging from $200 for basic models to $5,000+ for industrial-grade units. Retailers and manufacturers often provide financing or bulk purchase discounts.

Q: How does a vertical vacuum packaging machine differ from other types?

A: Vertical machines are space-efficient, ideal for liquids or unevenly shaped items, as bags are filled vertically. Horizontal models suit high-volume production of pre-cut bags. Choose based on packaging needs and workspace.

Q: What maintenance does a vacuum packing machine require?

A: Clean seals and chambers regularly to prevent debris buildup, replace worn gaskets, and check oil levels in pneumatic systems. Follow the manufacturer’s guidelines for optimal performance and longevity.

Q: Can a vacuum packaging machine handle delicate foods like berries?

A: Yes, but use pulse-mode settings to avoid crushing and select machines with adjustable vacuum strength. Pre-freeze delicate items or use specialized trays to protect them during sealing.

Q: What factors should I consider when buying a vacuum packaging machine?

A: Prioritize production volume, bag compatibility (e.g., material thickness), and automation features like dual chambers. Check warranty coverage and customer support for commercial use cases.

-

Automatic Drinking Line: AI Enhanced for Peak Efficiency

NewsAug.04,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Poultry Equipment

NewsAug.03,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Chicken Farming Automation&Durable PP Construction

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsAug.03,2025

-

Top Quality Pig Farrowing Pens for Enhanced Productivity

NewsAug.03,2025

-

Automatic Feeding Line System - Anping County Yize Metal Products Co., Ltd.

NewsAug.02,2025