Grading Standards for Machine Egg Sizes and Quality Assessment Techniques

அக் . 02, 2024 23:16 Back to list

Grading Standards for Machine Egg Sizes and Quality Assessment Techniques

Machine Egg Size Grading Enhancing Efficiency and Quality in the Poultry Industry

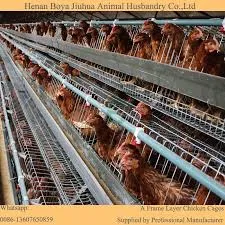

In the poultry industry, egg production is a significant sector that contributes to global food supplies. One crucial aspect of egg production is the grading of eggs, which ensures that they meet specific quality standards before reaching consumers. Traditionally, egg grading was done manually, a labor-intensive process that required skilled workers to assess the size and quality of each egg. However, with advancements in technology, machine egg size grading has become an efficient alternative that enhances productivity and ensures consistent quality.

Machine egg size grading involves the use of specialized equipment designed to automatically sort and classify eggs based on their size. This process typically includes multiple stages gathering, cleaning, sizing, and packing. High-quality machines are equipped with sophisticated sensors and software that can accurately measure the dimensions of each egg. By analyzing factors such as weight, length, and diameter, machines can categorize eggs into various sizes rapidly and with a high degree of precision.

One of the primary benefits of machine egg size grading is increased efficiency. Automated systems can process thousands of eggs per hour, significantly outpacing manual grading operations. This rapid sorting capability reduces the time between egg collection and distribution, allowing producers to deliver fresher products to market. Additionally, with a higher throughput, poultry farms can meet the demands of larger retailers and consumers who often require consistent and large supplies of eggs.

machine egg size grading

Furthermore, machine grading minimizes the potential for human error. Manual grading can lead to inconsistencies due to fatigue or subjective assessments, which may result in lower-quality eggs being sold. Automated systems, on the other hand, rely on precise measurements and algorithms, ensuring that eggs are graded uniformly. This consistency not only boosts the quality of the final product but also enhances consumer trust and satisfaction. Customers can expect that eggs are graded according to standardized sizes, which is vital for recipes and food manufacturing that rely on specific egg sizes.

The technology used in machine egg grading also allows for better inventory management. By integrating the grading process with inventory systems, producers can easily track the sizes and quantities of eggs being processed. This data-driven approach empowers producers to make informed decisions about production and sales, optimizing operational efficiency and reducing waste.

Moreover, machine egg size grading contributes to food safety standards. Automated systems often include cleaning and sanitization processes, reducing the likelihood of contamination. As consumers become increasingly concerned about food safety and quality, employing machine grading technologies helps producers align with industry regulations and consumer expectations.

In summary, machine egg size grading represents a pivotal advancement in the poultry industry, driving efficiency, quality, and safety. By automating the grading process, producers can enhance productivity while providing consistent and high-quality products to consumers. As technology continues to evolve, the integration of machine grading systems in egg production is likely to grow, leading to further innovations that benefit both producers and consumers alike. The future of the poultry industry looks promising as these technologies pave the way for more sustainable and efficient practices.

-

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025