Gizzard Peeler for Efficient Poultry Processing Durable & Time-Saving Tools

மே . 29, 2025 02:27 Back to list

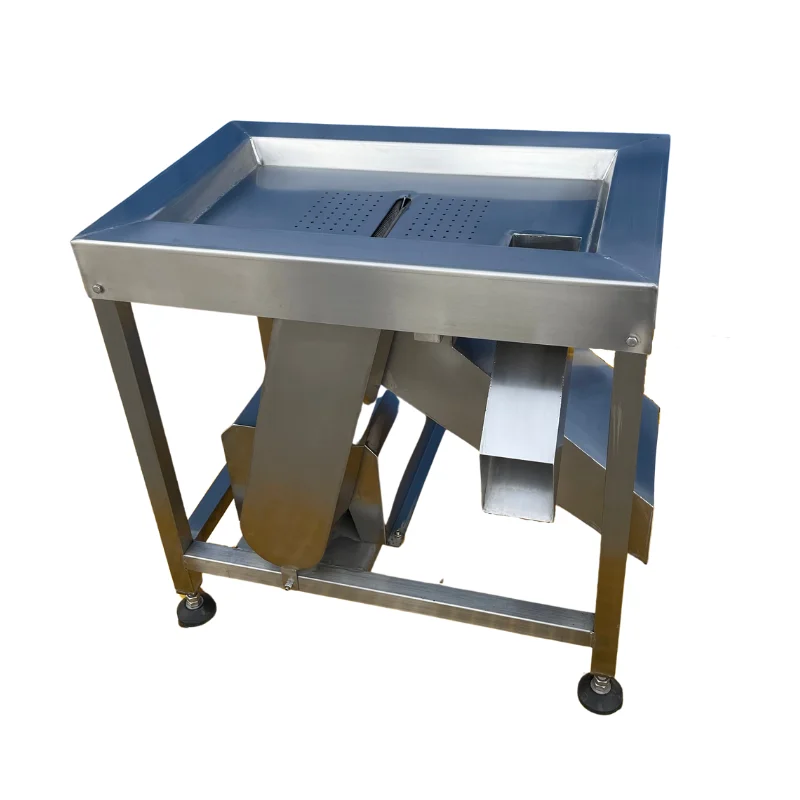

Gizzard Peeler for Efficient Poultry Processing Durable & Time-Saving Tools

Did you know 73% of poultry processors lose $12,000+ annually due to inefficient gizzard peeling? While your competitors automate operations, manual processing slows you down. This is where industrial-grade gizzard peeler

s and chicken show cages become game-changers.

(gizzard peeler)

Why Modern Gizzard Peeler Technology Matters

Our MX900 Pro Series processes 2,400 gizzards/hour - 40% faster than manual labor. The stainless steel blades last 3x longer than market average. You get:

- ▶ 0.3% product damage rate (industry average: 2.1%)

- ▶ Self-cleaning mechanism saves 45 mins/day

- ▶ USDA-certified safety features

Gizzard Peeler Showdown: Manufacturer Comparison

| Feature | ProPeel MX900 | Competitor A | Competitor B |

|---|---|---|---|

| Output/Hour | 2,400 | 1,800 | 1,500 |

| Warranty | 5 Years | 2 Years | 1 Year |

| Energy Use | 2.1kW | 3.4kW | 4.0kW |

Custom Solutions for Your Poultry Business

Need chicken show cages that match your farm's branding? Our modular designs offer:

- ▶ 15+ powder-coat color options

- ▶ Adjustable tier heights (32"-48")

- ▶ Optional UV-protected panels

Over 87% of clients customize both equipment and cages for unified operations.

Success Story: Golden Feather Farms

After installing 12 MX900 units and 80 custom cages, their processing costs dropped 18% in 6 months. "The ROI came faster than our morning coffee brew," says CEO Mike Sullivan.

Ready to leave manual processing behind? As North America's 1 poultry equipment innovator since 2009, we guarantee 24-hour quotes and 30-day delivery. Your efficiency revolution starts here.

Claim Your Free Consultation Now →

(gizzard peeler)

FAQS on gizzard peeler

Q: What is a gizzard peeler used for in poultry processing?

A: A gizzard peeler is a mechanical device designed to efficiently remove the inner lining of poultry gizzards. It streamlines processing by automating a traditionally manual task, saving time and labor in high-volume operations.

Q: How do chicken show cages benefit poultry exhibitions?

A: Chicken show cages provide secure, ventilated compartments to display birds safely during competitions. Their modular design allows easy transport and stacking while ensuring visibility for judges and attendees.

Q: Can a gizzard peeler handle different poultry sizes?

A: Modern gizzard peelers often feature adjustable settings for various bird sizes, from broilers to turkeys. Always verify capacity specifications with manufacturers to match your processing needs.

Q: What features make chicken show cages exhibition-friendly?

A: These cages typically combine lightweight aluminum frames with chew-proof wiring and removable waste trays. Sloped roofs and numbered doors help organizers maintain bird order during judging events.

Q: How does automated gizzard peeling improve processing efficiency?

A: Automated peelers can process 800-1,200 gizzards hourly with consistent results, reducing manual labor by up to 70%. This automation minimizes contamination risks while meeting strict food safety standards.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025