Efficient Poultry Scalder Techniques for Optimal Processing and Quality Enhancement

Septemba . 25, 2024 12:12 Back to list

Efficient Poultry Scalder Techniques for Optimal Processing and Quality Enhancement

The Importance of Poultry Scalders in Modern Processing

In the modern poultry processing industry, one of the essential steps in ensuring product quality and safety is the use of poultry scalders. This crucial equipment is designed to facilitate the removal of feathers from birds such as chickens, turkeys, and ducks, following slaughter. A well-functioning scalder plays a significant role in the overall efficiency of the processing line, affecting both the quality of the end product and the efficacy of subsequent processing steps.

Poultry scalding involves immersing the birds in hot water, typically maintained at temperatures between 140°F and 160°F (60°C to 71°C). The primary purpose of scalding is to loosen the feathers, making them easier to pluck during the evisceration process. Effective scalding not only enhances feather removal but also has implications for the skin condition of the poultry, preventing bruising and ensuring a more aesthetically pleasing product.

There are two main types of scalders used in poultry processing batch and continuous. Batch scalders are used for smaller operations, where birds are scalped in groups, while continuous scalders are designed for high-capacity processing plants. The choice between these systems depends largely on the scale of production and the specific requirements of the processing facility.

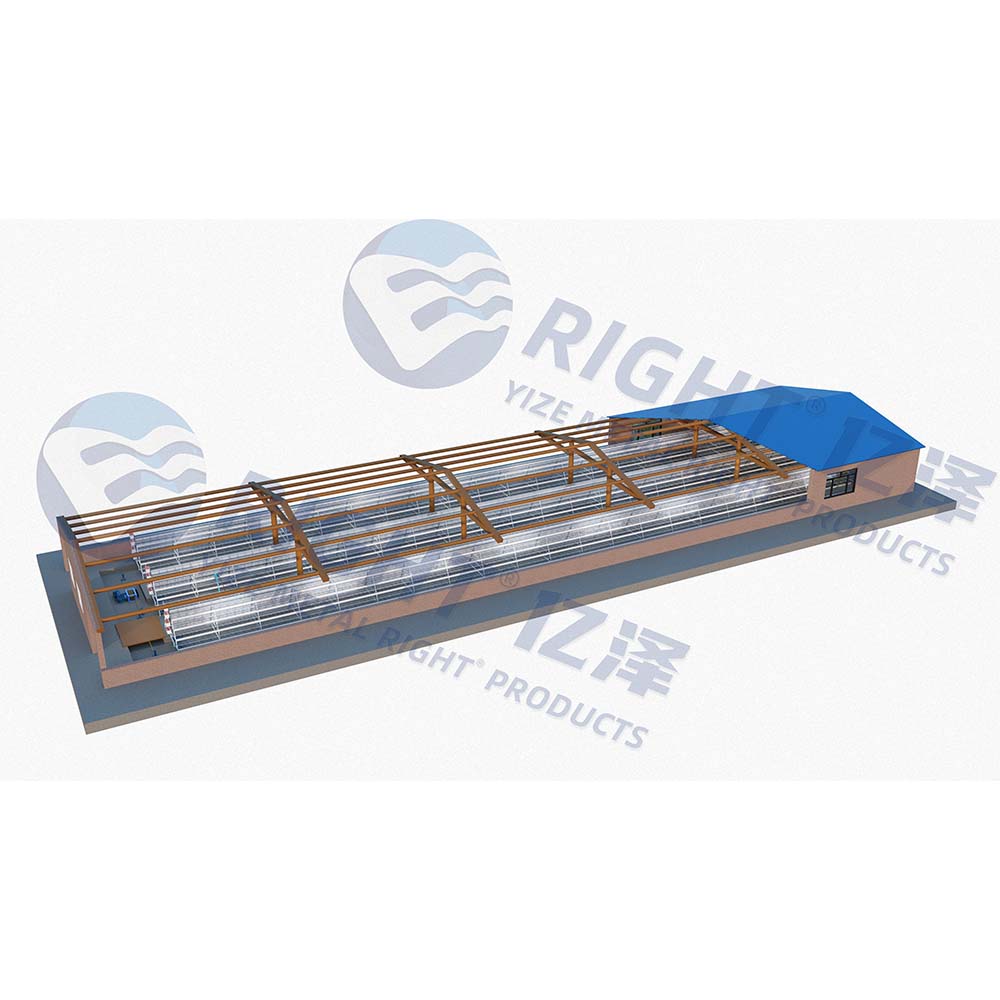

poultry scalder

Moreover, advancements in technology have led to the development of more sophisticated scalder designs that offer improved temperature control, water circulation, and hygiene. Modern scalder systems are often equipped with sensors and automated controls, ensuring that the water temperature remains consistent and that the scalding process is optimized. This not only improves feather removal rates but also minimizes the risk of over-scalding, which can result in damaged skin and reduced meat quality.

In addition to improving efficiency and product quality, proper scalding practices have significant implications for food safety. Inadequate scalding can lead to increased bacterial load on the surface of the poultry, posing health risks to consumers. By ensuring optimal scalding conditions, processors can help mitigate these risks, adhering to food safety standards and maintaining consumer trust.

In conclusion, poultry scalders are integral to the poultry processing industry. By facilitating effective feather removal and ensuring product quality, these machines play a vital role in producing safe, high-quality poultry products. As the industry continues to evolve, ongoing advancements in scalder technology will further enhance processing efficiency and food safety, solidifying their importance in modern poultry operations.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker-Anping County Yize Metal Products Co., Ltd.

NewsJul.30,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable Construction&Easy Maintenance

NewsJul.30,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker&Durable Poultry Farming Solution

NewsJul.30,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Equipment

NewsJul.29,2025