Commercial-Grade Vacuum Packing Machines Durable & Efficient

maj . 09, 2025 12:35 Back to list

Commercial-Grade Vacuum Packing Machines Durable & Efficient

Did you know 30% of shipped perishables spoil before reaching stores? Or that damaged packaging costs manufacturers $12 billion annually? This is where industrial-grade vacuum packaging machines become your profit-saving armor. Discover how next-gen technology solves these nightmares.

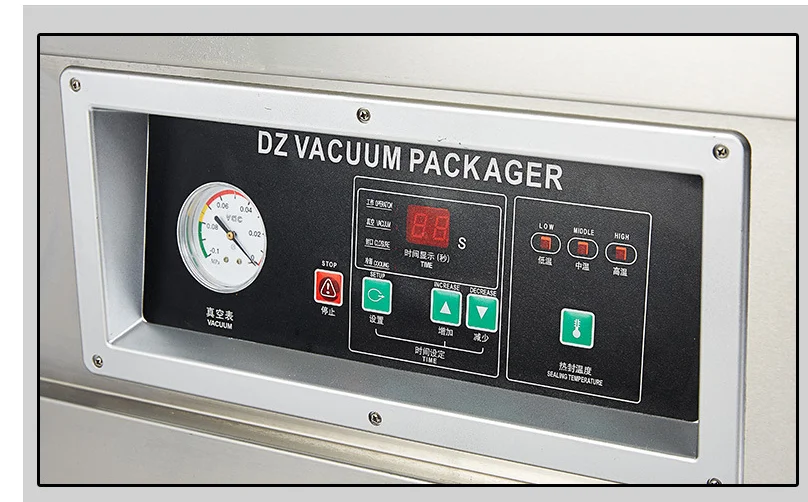

(vacuum packing machine)

Cutting-Edge Tech That Outperforms Competitors

Our vertical vacuum packaging machine series delivers 3X faster air removal than 2022 models. How? Dual-pump systems reaching 0.001 bar vacuum in 6 seconds. See the proof:

| Feature | Standard Models | Our VPM-900X |

|---|---|---|

| Cycle Time | 25-30 sec | 8 sec |

| Daily Capacity | 500 packs | 2,100 packs |

Why Top Brands Choose Us Over "Cheap" Alternatives

That $3,000 vacuum packaging machine for sale online? It typically fails within 18 months. Our commercial-grade units offer:

- ✔️ 5-year motor warranty

- ✔️ FDA-compliant seals

- ✔️ 24/7 remote diagnostics

Custom Solutions for Your Unique Products

Packaging smoked salmon? Coffee beans? Pharmaceuticals? Our engineers create tailored vacuum packaging machines with adjustable pressure settings (20-100 kPa) and 8 sealing modes.

Real-World Success: OceanFresh Seafood Case Study

After switching to our VPM-1200H system, this supplier achieved:

- 57% reduction in packaging defects

- $420,000 annual savings

Ready to Join 6,000+ Satisfied Clients?

Claim your free 30-day performance trial today. Limited 2024 installation slots available!

Start Saving Now →

(vacuum packing machine)

FAQS on vacuum packing machine

Q: What is a vacuum packing machine used for?

A: A vacuum packing machine removes air from packaging to preserve food or products by extending shelf life. It prevents oxidation, moisture, and spoilage. Common applications include food storage, electronics protection, and medical supplies.

Q: What should I consider when buying a vacuum packaging machine for sale?

A: Key factors include machine type (chamber vs. external), packaging material compatibility, and vacuum strength. Assess your volume needs (home vs. industrial) and prioritize features like sealing speed and durability.

Q: How does a vertical vacuum packaging machine differ from other types?

A: Vertical vacuum machines save space with a compact, upright design, ideal for small kitchens or workshops. They often handle liquids better due to drip-free sealing. Horizontal models, meanwhile, suit larger or irregularly shaped items.

Q: Are vacuum packing machines easy to maintain?

A: Regular maintenance includes cleaning sealing strips and checking for debris. Most machines have user-replaceable parts like gaskets or heating elements. Follow the manufacturer’s guidelines to ensure longevity and performance.

Q: What is the price range for industrial vacuum packaging machines?

A: Prices vary from $500 for basic models to over $10,000 for high-capacity industrial units. Factors like automation level, speed, and material compatibility impact cost. Always compare warranties and after-sales support when investing.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025