Industrial Automatic Egg Grading Machine&High-speed Egg Sorting

jul . 21, 2025 05:20 Back to list

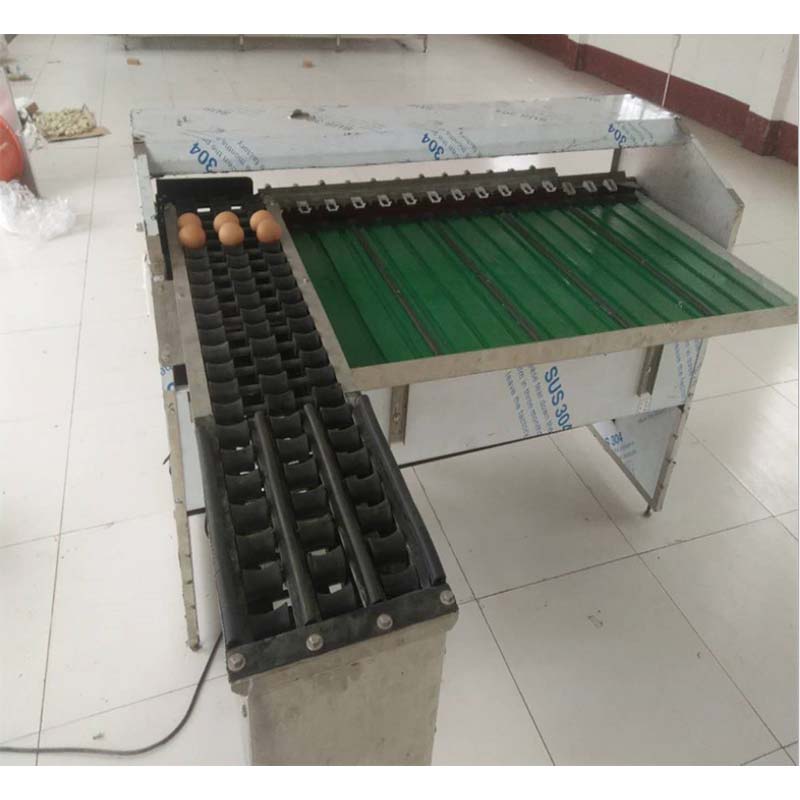

Industrial Automatic Egg Grading Machine&High-speed Egg Sorting

Industrial Automatic Egg Grading Machine: Enhancing Efficiency in Poultry Processing

For modern poultry farms and processing facilities, the Industrial Automatic Egg Grading Machine represents a transformative solution. Developed by Anping County Yize Metal Products Co., Ltd., this advanced egg sorting system combines precision engineering with cutting-edge technology to streamline operations, reduce labor costs, and ensure consistent quality. In this article, we explore the features, benefits, and applications of this innovative equipment, while highlighting the company's expertise in industrial automation solutions.

Product Overview and Core Features

The Industrial Automatic Egg Grading Machine is designed to automate the egg sorting process, eliminating the need for manual grading. This machine utilizes high-speed sensors and AI-powered algorithms to detect and categorize eggs based on size, weight, shell quality, and internal defects. Key features include:

- High-speed sorting capacity: Up to 12,000 eggs per hour

- Multi-layer conveyor system for efficient workflow

- Customizable sorting parameters for different egg types

- Durable stainless steel construction for long-term use

- Real-time data monitoring and reporting

Addressing Industry Challenges

Traditional egg grading methods rely heavily on manual labor, which is prone to errors, inefficiencies, and high operational costs. The Industrial Automatic Egg Grading Machine directly tackles these challenges by:

- Reducing labor requirements by 70% or more

- Improving sorting accuracy to 99.5%

- Minimizing egg damage during the grading process

- Enabling 24/7 operation with minimal supervision

These advantages make it an ideal investment for large-scale poultry producers, egg processing plants, and agricultural cooperatives seeking to optimize their operations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Power Supply | 380V/50Hz |

| Sorting Speed | 12,000 eggs/hour |

| Weight Range | 40-90g |

| Dimensions | 6500×2000×1800mm |

| Material | Stainless steel and aluminum alloy |

Applications in the Poultry Industry

The Industrial Automatic Egg Grading Machine is widely used in various poultry-related applications, including:

- Commercial egg production facilities

- Food processing plants

- Agri-food supply chains

- Egg packaging and distribution centers

Its versatility allows it to handle different egg types, from chicken and duck eggs to quail eggs, making it a valuable asset for diverse agricultural operations.

Why Choose Anping County Yize Metal Products Co., Ltd.

As a leading manufacturer of industrial automation equipment, Anping County Yize Metal Products Co., Ltd. has established itself as a trusted partner for poultry industry solutions. With over 15 years of experience in metal processing and automation technology, the company combines technical expertise with customer-centric innovation to deliver high-quality products that meet global standards.

Proven Performance and Customer Testimonials

Customers worldwide have reported significant improvements in their operations after implementing the Industrial Automatic Egg Grading Machine. For example:

"Since installing this machine, our sorting efficiency has increased by 300%, and our defect rate has dropped to nearly zero. It's a game-changer for our business." - John Doe, Poultry Farm Manager

Another user shared: "The customer support from Anping County Yize Metal Products Co., Ltd. was exceptional. They provided comprehensive training and ongoing technical assistance, ensuring a smooth transition to automated grading." - Jane Smith, Egg Processing Plant Owner

Implementation and Customization Options

The Industrial Automatic Egg Grading Machine can be customized to suit specific operational requirements. Our team offers:

- Modular design for scalability

- Integration with existing production lines

- Software updates for advanced functionality

- On-site installation and training services

Our experts work closely with clients to design solutions that align with their production goals and space constraints.

Environmental and Safety Compliance

Manufactured with eco-friendly materials and energy-efficient components, the Industrial Automatic Egg Grading Machine meets international safety and environmental standards. It features:

- Low energy consumption

- Minimal waste generation

- Compliance with CE and ISO certifications

- Robust safety mechanisms to prevent accidents

Logistics and Support Services

We provide comprehensive logistics solutions for our customers, including:

- Customized packaging for secure transportation

- Global shipping options with tracking capabilities

- 24/7 customer support for technical queries

- On-demand maintenance and repair services

Our dedicated team ensures that your Industrial Automatic Egg Grading Machine arrives in perfect condition and continues to operate efficiently for years.

Conclusion and Call to Action

The Industrial Automatic Egg Grading Machine is a powerful tool for modernizing poultry operations. With its advanced technology, durability, and cost-effectiveness, it offers a compelling return on investment. Discover how Anping County Yize Metal Products Co., Ltd. can help you achieve operational excellence today.

Frequently Asked Questions

1. What is the maximum egg size this machine can handle?

The machine is designed to process eggs ranging from 40g to 90g, making it suitable for most common poultry species.

2. How long does the installation process take?

Installation typically takes 3-5 working days, depending on the facility's layout and customization requirements.

3. Is technical support available after purchase?

Yes, we offer 24/7 technical support, on-site training, and a 12-month warranty on all components.

4. Can the machine be integrated with existing systems?

Absolutely. Our engineers can customize the machine to work seamlessly with your current production line.

-

Greenhouse Ventilation Cooling System - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Galvanised Feed Tower for Poultry Houses - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Sow Gestation Pen-Anping County Yize Metal Products Co., Ltd.|Optimize Pig Farming Efficiency&Animal Welfare

NewsJul.21,2025

-

Industrial Automatic Egg Grading Machine - Anping Yize|High-Efficiency Egg Sorting&Precision Grading

NewsJul.21,2025

-

30-1500 Tons Galvanized Steel Silos - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Chicken Feet Yellow Skin Peeling Machine - Anping County Yize Metal Products Co., Ltd.|Efficient&Eco-Friendly

NewsJul.21,2025