Chicken Feet Processing Equipment for Efficient and Hygienic Preparation

Dec . 09, 2024 19:39 Back to list

Chicken Feet Processing Equipment for Efficient and Hygienic Preparation

The Importance of Chicken Feet Processing Machines in the Poultry Industry

In the poultry industry, chicken feet are often considered a valuable byproduct rather than waste. With the global interest in culinary traditions that elevate chicken feet to gourmet status, processing these appendages has become a burgeoning industry. To maximize the potential of chicken feet, modern technology has introduced specialized chicken feet processing machines designed to streamline and enhance the efficiency of production. This article explores the significance of these machines, the processing steps involved, and their impact on the poultry industry.

Understanding the Market for Chicken Feet

Chicken feet are a delicacy in many cultures, particularly in Asian countries such as China, the Philippines, and Thailand. They are used in various dishes, including soups and stews, and can also be fried or dried as crunchy snacks. This demand has led to an increased focus on chicken feet processing, making it essential for poultry businesses to adopt efficient machinery capable of meeting market needs. With a growing global market, the proper processing of chicken feet is not only lucrative but also a sustainable way to utilize all parts of the chicken.

Key Processing Steps Involved

The processing of chicken feet involves several critical steps, each requiring specific machinery for optimal results

1. Cleaning The first step in processing chicken feet is thorough cleaning. Machines designed for this purpose use high-pressure water jets to remove dirt, feathers, and other impurities. This ensures that the feet are sanitized and ready for the subsequent processing stages.

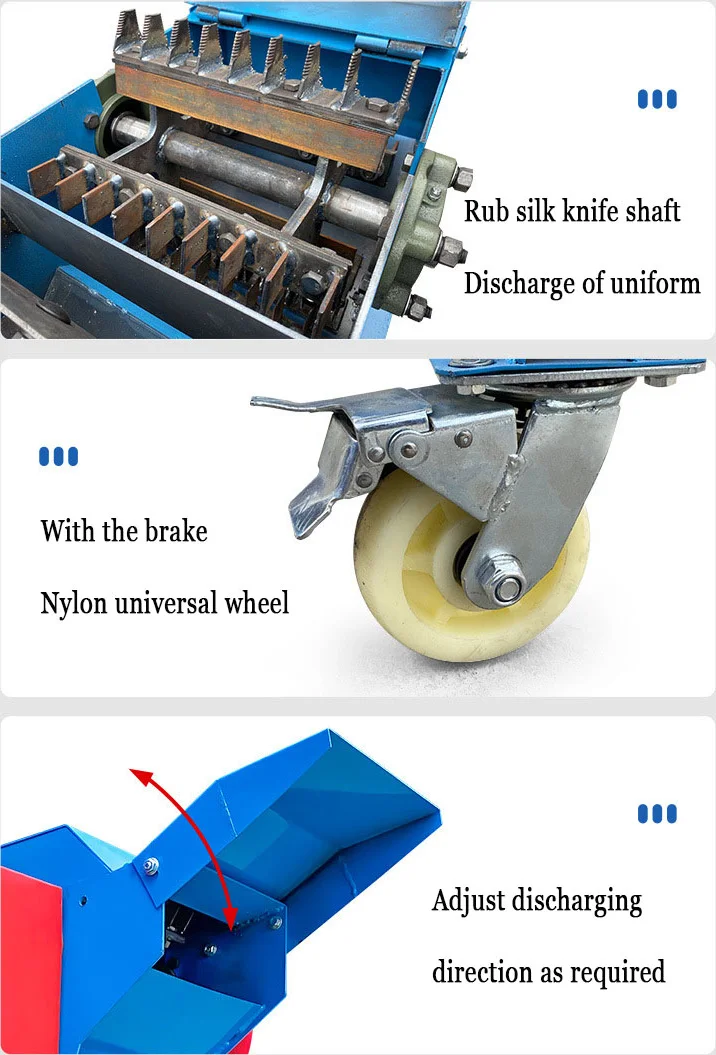

2. Deboning and Deskinning After cleaning, the feet are subjected to machines that can effectively debone and deskin them. The ability to remove the outer skin while preserving the structure of the feet is essential, as it affects both the appearance and the texture of the final product. Advanced machines use specialized blades to accomplish this task with precision.

chicken feet processing machine

3. Blanching Blanching is a crucial step that enhances flavor and texture while removing any remaining bacteria. Processing machines equipped with steaming or hot water systems can efficiently blanch chicken feet, ensuring they are cooked evenly and thoroughly.

4. Cooling and Drying After blanching, cooling machines are employed to bring the temperature of the chicken feet down rapidly, preventing overcooking and maintaining quality. Following cooling, drying machines remove excess moisture, which is crucial for preserving the product and preventing spoilage.

5. Packaging Once processed, chicken feet are packaged for distribution. Automated packaging machines play a vital role in this stage, ensuring that products are sealed securely to maintain freshness. Picture a facility where the entire process flows seamlessly, with products being packaged right after processing to meet market demand quickly.

Impact on the Poultry Industry

The introduction of chicken feet processing machines has transformed the way poultry businesses operate. By incorporating automation and advanced technology, companies can significantly increase their output while reducing labor costs. The efficiency of these machines allows processors to meet the growing demand for chicken feet in both local and international markets.

Moreover, the reduction of waste contributes to a more sustainable poultry industry. Using every part of the chicken, including feet, minimizes environmental impact and maximizes profit margins for producers. This commitment to utilizing byproducts resonates with consumers who are increasingly focused on sustainability and responsible sourcing in their purchasing decisions.

Conclusion

Chicken feet processing machines represent a vital aspect of the poultry industry, bridging the gap between traditional culinary practices and modern production efficiency. As global tastes evolve and the demand for chicken feet grows, investing in advanced processing technology becomes essential for poultry businesses aiming to thrive in a competitive market. The effective processing of chicken feet not only contributes to profitability but also aligns with sustainable practices that benefit producers and consumers alike. By embracing technological advancements, the poultry industry is poised to unlock the full potential of this often-overlooked byproduct, ensuring its place in the culinary world of tomorrow.

-

Automatic Feeding Line System - Anping Yize | Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System - Anping Yize|Poultry Efficiency&Durability

NewsJul.29,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable PP Material&Easy Maintenance

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025