egg tray making machine fully automatic

Dhj . 30, 2024 02:16 Back to list

egg tray making machine fully automatic

The Fully Automatic Egg Tray Making Machine Revolutionizing Packaging Solutions

In recent years, the demand for sustainable packaging solutions has surged dramatically, especially in the food industry. One innovation that stands out in this niche is the fully automatic egg tray making machine. This advanced piece of equipment is not only transforming the way we package eggs but is also setting new standards in efficiency and environmental sustainability.

What is an Egg Tray Making Machine?

An egg tray making machine is designed to produce egg trays from recycled paper pulp. The process involves several steps, including pulping, molding, drying, and packaging. The fully automatic version of this machine streamlines these processes with little to no manual labor, thereby increasing production capacity and consistency in quality.

Features and Benefits

1. High Efficiency A fully automatic egg tray making machine operates with minimal human intervention. It can produce thousands of trays per hour, making it a valuable asset for large-scale egg production businesses. With automation, the entire production line is optimized for speed, leading to increased profitability.

2. Energy Conservation Modern machines are designed with energy-efficient technologies. By utilizing waste paper as raw material and employing energy-saving drying systems, manufacturers can significantly reduce their carbon footprint, contributing to a greener planet.

3. Customizable Production These machines can often be adjusted to create different tray sizes and styles. This flexibility allows manufacturers to produce trays that cater specifically to various types of eggs, including chicken, quail, and duck eggs, as well as accommodating various packaging requirements.

4. Reduced Labor Costs With automated systems in place, the need for a large workforce is mitigated. This not only reduces labor costs but also minimizes the risk of human error, resulting in a more consistent product output.

egg tray making machine fully automatic

5. Eco-Friendly Production By using recycled paper pulp as the primary material, egg tray production aligns with sustainable practices. The products are biodegradable, making them an environmentally responsible choice for egg packaging. This focus on sustainability is critical as consumers increasingly favor eco-friendly products.

The Production Process

The fully automatic egg tray machine follows a systematic process

- Pulping Waste paper is broken down into pulp through mechanical and chemical processes. This pulp is then mixed with water to achieve the desired consistency. - Molding The pulp is transferred to molding dies that shape it into egg tray forms. This stage often involves suction or pressure to ensure that the trays have the required strength and durability.

- Drying Once molded, the trays are dried. This can be done using natural sunlight or advanced drying systems that utilize heat exchangers to minimize energy consumption.

- Packing After drying, the trays are counted, packed, and prepared for shipment. Automation ensures that each step flows smoothly into the next, significantly reducing downtime.

Conclusion

The fully automatic egg tray making machine is a prime example of how technology can improve traditional processes while promoting sustainability. With its high efficiency, energy conservation, and reduced labor costs, it has become an indispensable tool for egg producers. Furthermore, it supports the global shift toward eco-friendly packaging solutions, aligning with consumers' growing expectations for sustainable practices.

Investing in a fully automatic egg tray making machine is not just a smart business decision; it is a commitment to innovation and environmental stewardship. As the demand for sustainable packaging continues to rise, businesses equipped with this technology will undoubtedly have a competitive edge in the market. Thus, the future of egg packaging looks promising, driven by automation and sustainability.

-

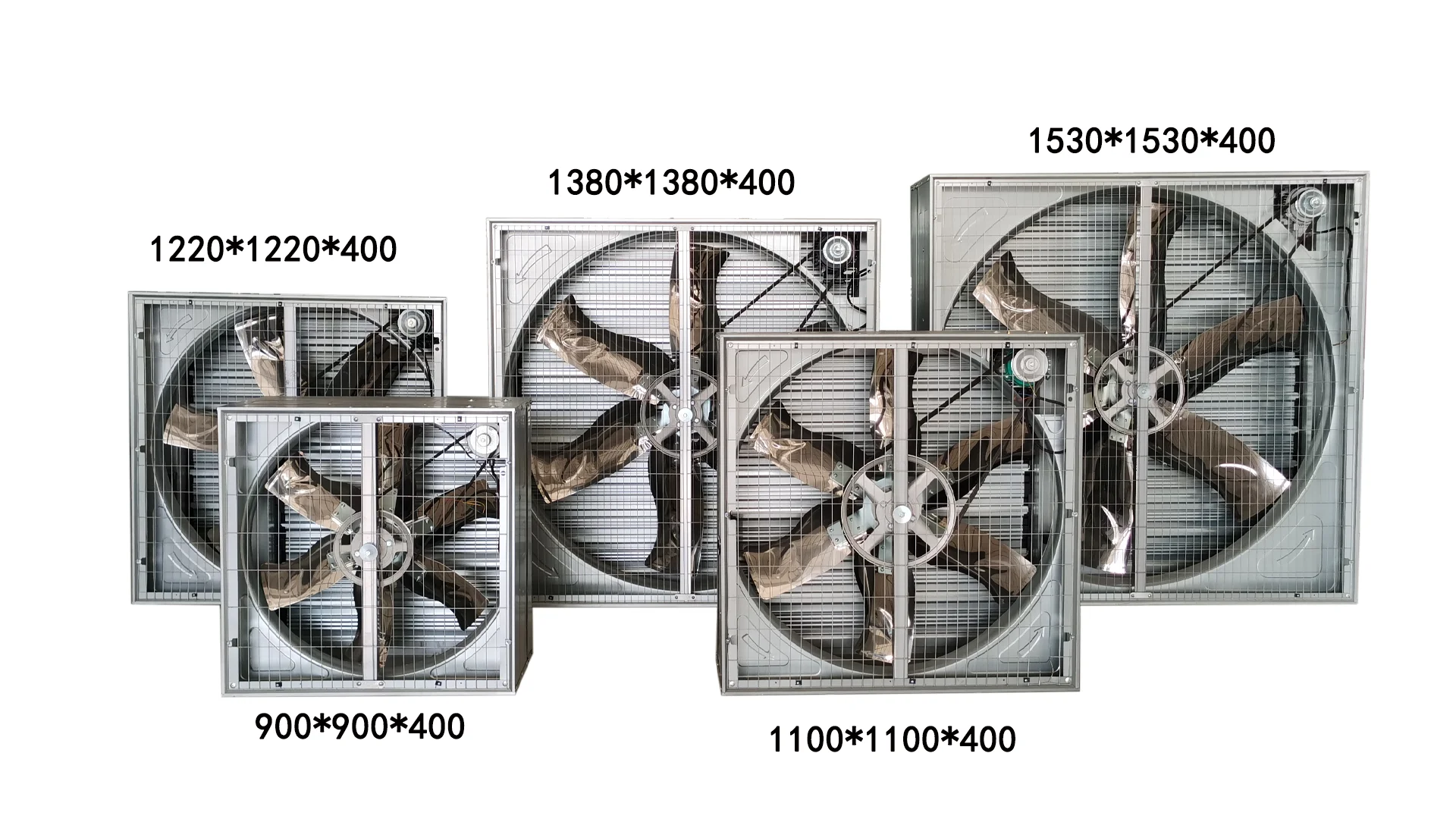

High Performance Exhaust Fan – Efficient Ventilation Solutions for Home

NewsJun.10,2025

-

High-Quality Gestation Pen for Sows Durable Mobile Pig Pen & Simple Pig Pen Solutions

NewsJun.10,2025

-

High Quality Rabbit Cage Double Tier Designs & Welded Wire Mesh Supplier

NewsJun.10,2025

-

Floating Fish Feed Machine - High Efficiency Floating Fish Feed Extruder for Small Scale Production

NewsJun.10,2025

-

Premium Poultry Housing Solutions Mobile & Commercial Free Range Options

NewsJun.10,2025

-

Industrial FRP Fans Corrosion-Resistant Blades & Centrifugal Systems

NewsJun.09,2025