Equipment for Processing Chicken Feet Efficiently and Effectively in Food Manufacturing

Dec . 25, 2024 00:42 Back to list

Equipment for Processing Chicken Feet Efficiently and Effectively in Food Manufacturing

The Importance of Chicken Feet Processing Machines in Modern Agriculture

In the realm of poultry processing, chicken feet have garnered significant attention due to their nutritional value and growing demand in various culinary traditions across the globe. As a result, the importance of chicken feet processing machines has become increasingly evident. These machines are pivotal in transforming raw chicken feet into market-ready products, enabling producers to meet consumer demands efficiently.

Understanding Chicken Feet Processing

Chicken feet are rich in collagen and essential nutrients, making them a sought-after ingredient in soups, stews, and various dishes, particularly in Asian cuisines. However, processing chicken feet requires specialized equipment to ensure hygiene, quality, and efficiency.

The processing of chicken feet involves several steps, including cleaning, sterilizing, peeling, trimming, and packaging. Each of these stages demands precise operations that can be optimized through the use of advanced processing machines. This is where chicken feet processing machines come into play.

Key Features of Chicken Feet Processing Machines

Modern chicken feet processing machines are designed to streamline the processing line. They incorporate various features that facilitate the efficient handling of chicken feet

1. Automated Cleaning Systems These machines often have built-in washing systems that thoroughly remove contaminants and feathers from chicken feet. The automation of the cleaning process ensures consistency and reduces labor costs.

2. Scalding and De-feathering A critical step in processing chicken feet is scalding to loosen the skin and feathers. Advanced machines come equipped with scalding tanks and de-feathering mechanisms that enhance the yield and quality of the final product.

3. Trimming and Quality Control Processing machines are equipped with cutting tools that trim excess skin and nails from the feet, ensuring that the product meets market standards. Some machines even include camera systems for quality control, allowing for real-time monitoring and adjustments.

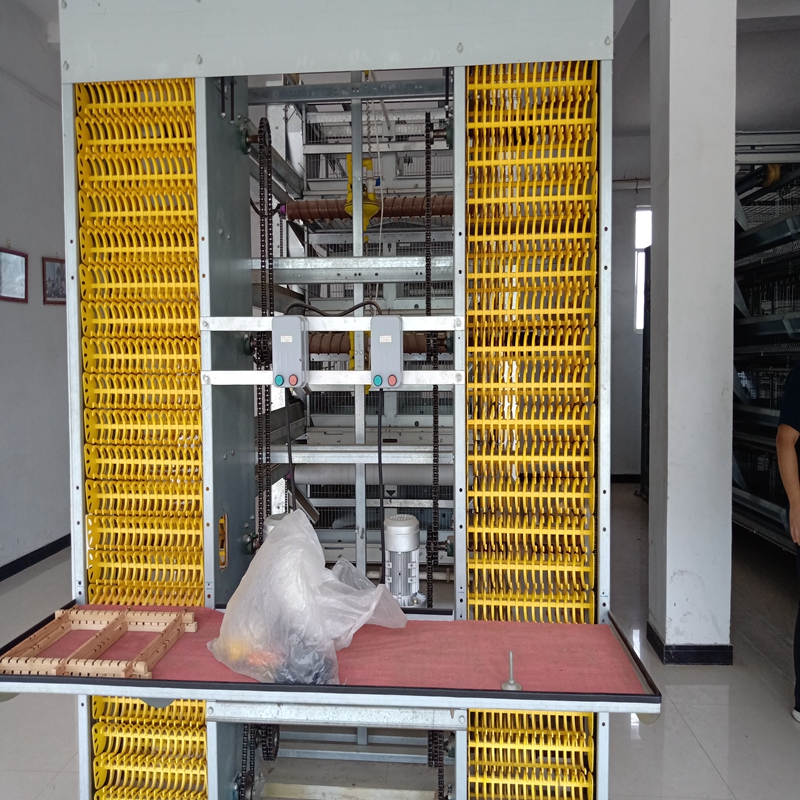

chicken feet processing machine

4. Packaging Solutions After processing, the efficient packaging of chicken feet is essential for preserving freshness and ensuring hygienic transport. Modern processing machines often integrate packaging systems that use vacuum sealing or modified atmosphere packaging to extend shelf life.

Economic Benefits

Investing in chicken feet processing machines presents myriad economic advantages. With the demand for chicken feet on the rise, particularly in emerging markets, poultry producers can capitalize on this trend by incorporating efficient processing technologies. These machines not only enhance productivity but also reduce labor costs by minimizing the need for manual intervention.

Moreover, by improving product quality and consistency, producers can attract premium prices for their finished products. This is especially important in competitive markets where consumers prefer high-quality, safe food options.

Environmental Considerations

Another vital aspect of chicken feet processing machines is their contribution to sustainability. By streamlining processing operations, these machines help reduce waste and improve overall resource efficiency. For instance, any by-products generated during processing can be repurposed for animal feed or other applications, minimizing environmental impact.

Conclusion

The advancement of chicken feet processing machines is revolutionizing the poultry industry. As the global market continues to embrace chicken feet for their nutritional benefits and culinary versatility, the efficiency and quality assurance offered by modern processing technologies will become essential. For poultry producers, investing in such machines is not just a step toward enhancing productivity; it is a strategic move to position themselves favorably in a burgeoning market.

In summary, chicken feet processing machines not only facilitate the processing of one of the most undervalued parts of the chicken but also contribute to a brighter economic future for poultry producers while addressing environmental concerns. As technology continues to evolve, so too will the practices surrounding chicken feet processing, paving the way for continued growth and innovation in the industry.

-

Automatic Feeding Line System Pan Feeder Nipple Drinker-Anping County Yize Metal Products Co., Ltd.

NewsJul.30,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Durable Construction&Easy Maintenance

NewsJul.30,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Pan Feeder Nipple Drinker&Durable Poultry Farming Solution

NewsJul.30,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System-Pan Feeder Nipple Drinker|Anping County Yize Metal Products Co., Ltd.

NewsJul.29,2025

-

Automatic Feeding Line System - Pan Feeder Nipple Drinker|Broiler Farming Equipment

NewsJul.29,2025