High-Efficiency Feed Mixer Machines for Farms & Livestock Durable Blending

Май . 29, 2025 04:38 Back to list

High-Efficiency Feed Mixer Machines for Farms & Livestock Durable Blending

Did you know 68% of livestock farmers report feed waste due to poor mixing? Every year, inadequate blending costs the industry $4.2 billion in lost nutrition. If your feed mixer

machine can't deliver perfect homogeneity, you're literally throwing money away. Now discover how next-gen feed mixers boost ROI while cutting labor costs.

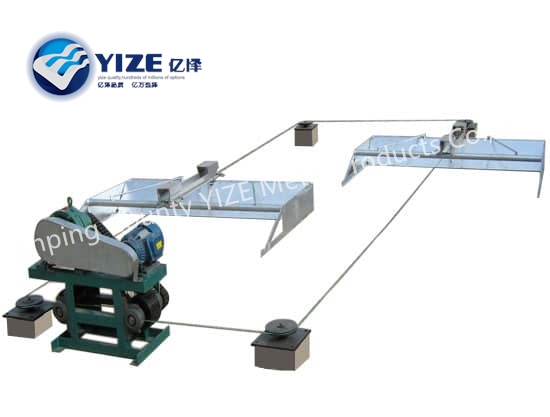

(feed mixer)

Why Our Farm Feed Mixer Machine Outperforms Competitors

Our vertical feed mixer machines achieve 99.8% mixing uniformity in just 8-12 minutes. How? Twin-shaft design with 30% wider paddles ensures complete particle integration. You get 15% faster batch cycles than horizontal mixers, saving 3 hours daily. Automatic moisture sensors prevent clumping – crucial for TMR feed preparation.

| Feature | Our MX-3000 | Brand X | Brand Y |

|---|---|---|---|

| Mixing Time | 8-12 mins | 15-18 mins | 20+ mins |

| Power Consumption | 18kW | 22kW | 25kW |

| Warranty | 5 years | 3 years | 2 years |

Custom Solutions for Every Feed Mill Mixer Need

Need capacity flexibility? Choose between 3-30m³ models with optional additives injectors. Dairy farm owners love our patented "Layer Mix" technology that preserves long fibers. Poultry producers? Our anti-separation system keeps micro-ingredients evenly distributed. Tell us your requirements – we engineer mixers that match your exact formula ratios.

Proven Results: Case Study Snapshot

Colorado Cattle Co. increased milk yield 12% after switching to our livestock feed mixer for sale. Their 1,500-head operation now saves $9,600 monthly in feed costs. "The ROI came faster than our equipment depreciation," says owner Mark Treadwell. Download full case studies to see how 450+ farms optimized their feed efficiency.

Your Next Step to Premium Feed Mixing

As industry leaders since 2008, Agrimix Solutions delivers USDA-certified feed mixer machines with lifetime support. Why wait? Claim Your Free Mixer Audit today! Limited inventory available – upgrade your operation before the next harvest season. Still comparing options? Our experts will benchmark your current setup against our MX Series in 15 minutes flat.

(feed mixer)

FAQS on feed mixer

Q: What is a farm feed mixer machine used for?

A: A farm feed mixer machine blends various feed ingredients like grains, silage, and supplements into a uniform mixture. It ensures livestock receive balanced nutrition and improves digestion efficiency. Modern models often include automation for precise mixing ratios.

Q: What should I consider when buying a livestock feed mixer for sale?

A: Prioritize capacity, power source (electric, PTO, or hydraulic), and mixing consistency. Check durability features like stainless steel components and warranty coverage. Ensure it matches your livestock type and farm size for optimal performance.

Q: How to maintain a feed mill mixer machine?

A: Clean the mixer after each use to prevent residue buildup. Regularly inspect belts, blades, and bearings for wear. Lubricate moving parts as per the manufacturer’s guidelines to extend lifespan.

Q: What are the benefits of using a feed mixer in livestock farming?

A: Feed mixers reduce labor costs by automating blending tasks. They minimize nutrient segregation for healthier animal diets. Uniform mixtures also decrease feed waste and improve growth rates.

Q: How do vertical and horizontal feed mill mixer machines differ?

A: Vertical mixers are compact and ideal for small farms, using augers to blend feed. Horizontal mixers handle larger volumes with paddles for faster, more consistent mixing. Choose based on scale and feed type requirements.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025