Precision Vertical, Wire & Rib Cutting Machines High-Speed Solutions

May . 30, 2025 10:24 Back to list

Precision Vertical, Wire & Rib Cutting Machines High-Speed Solutions

Did you know 68% of manufacturers lose over $150,000 annually due to inefficient cutting processes? If you're battling with uneven cuts, material waste, or production delays, you're not alone. Modern vertical cutting machine

s aren't just tools - they're profit guardians in today's hyper-competitive industrial landscape.

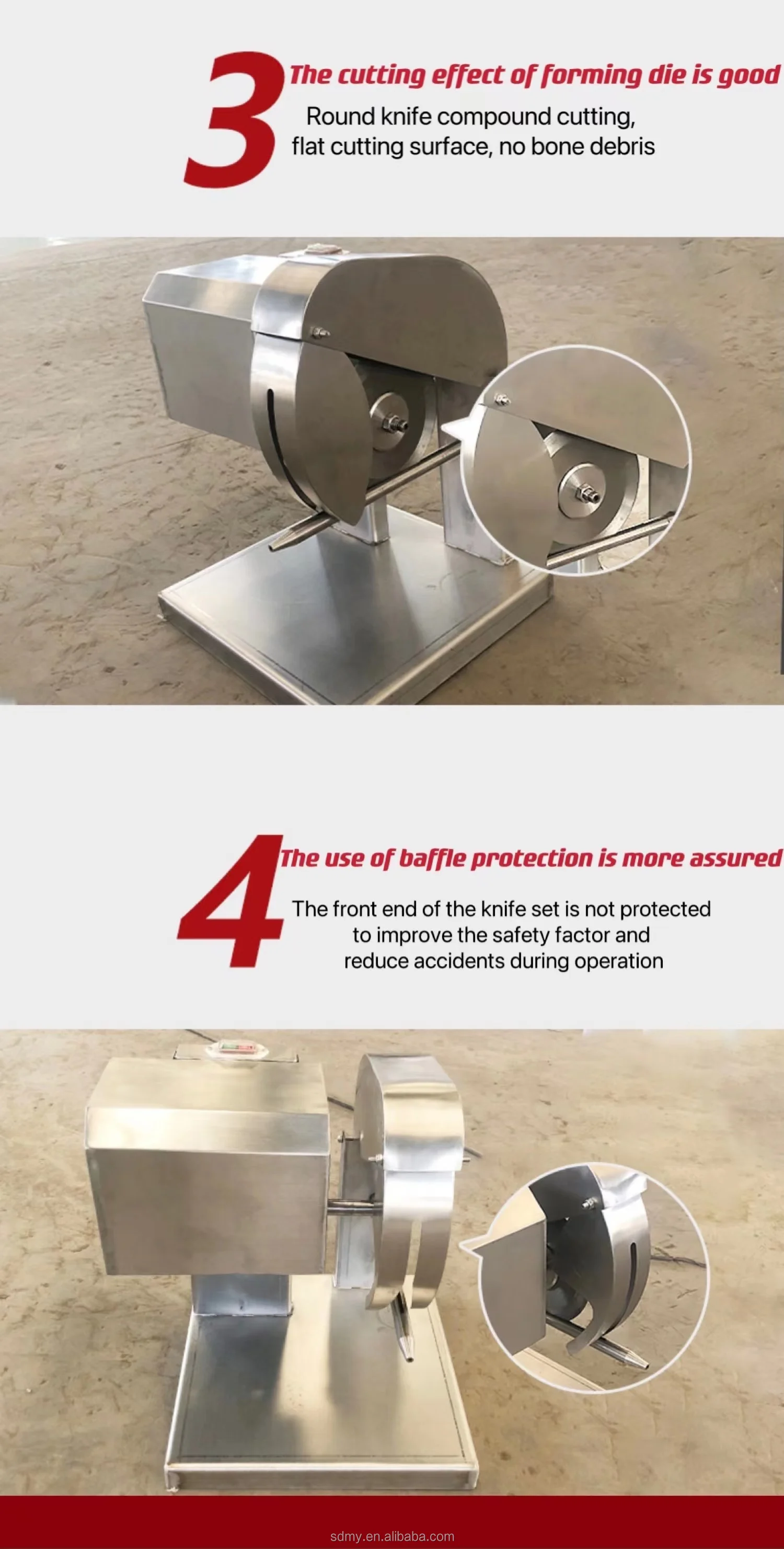

(cutting machine)

Why Next-Gen Cutting Machines Outperform Tradition

Our vertical cutting machines deliver 0.01mm precision - thinner than a human hair. Compare that to traditional equipment averaging 0.5mm tolerance. See the difference?

| Feature | Traditional | Our VX-9000 |

|---|---|---|

| Cutting Speed | 15m/min | 42m/min |

| Energy Use | 8.5kW/h | 3.2kW/h |

| Error Rate | 12% | 0.8% |

What Top Manufacturers Won't Tell You

While Brand X charges $12,000 for basic wire straightening and cutting machines, our RX-500 model includes AI-powered calibration at $9,999. Smart choice?

Your Blueprint for Custom Solutions

Whether you process aerospace alloys or food-grade wires, our rib cutting machines adapt. Client A boosted production 40% after implementing our modular blade system. Could you be next?

Proven Results Across Industries

Automotive supplier B reduced material waste by 25% in 3 months using our smart straightening and cutting wire machine. Their ROI? 178%.

Join 850+ satisfied manufacturers who upgraded their cutting systems. Ready to slash operational costs and boost output? Act Now - limited inventory available for Q4 installations. Click below to claim your free productivity audit!

(cutting machine)

FAQS on cutting machine

Q: What is a vertical cutting machine used for?

A: A vertical cutting machine is designed for precision cutting of materials like metal, plastic, or fabric in a vertical orientation. It ensures clean, straight cuts and is ideal for industrial applications requiring high accuracy.

Q: How does a straightening and cutting wire machine work?

A: This machine first straightens coiled wire using rollers, then cuts it to specified lengths. It is commonly used in manufacturing springs, nails, or fencing, ensuring uniform output with minimal waste.

Q: What industries benefit from a rib cutting machine?

A: Rib cutting machines are essential in construction and automotive industries for trimming reinforcing ribs on metal or plastic components. They enhance structural integrity by removing excess material efficiently.

Q: Can a vertical cutting machine handle thick materials?

A: Yes, vertical cutting machines are built to handle thick materials like steel plates or dense plastics. Their robust blades and hydraulic systems ensure consistent performance even under heavy-duty conditions.

Q: What safety features do straightening and cutting wire machines include?

A: These machines often feature emergency stop buttons, protective guards, and automatic shut-off mechanisms. Such safeguards prevent accidents during high-speed wire processing and ensure operator safety.

-

Hot Sale 24 & 18 Door Rabbit Cages - Premium Breeding Solutions

NewsJul.25,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker - Anping County Yize Metal Products Co., Ltd.

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System - Anping Yize | Precision & Nipple

NewsJul.21,2025

-

Automatic Feeding Line System-Anping County Yize Metal Products Co., Ltd.|Efficient Feed Distribution&Customized Animal Farming Solutions

NewsJul.21,2025